Special control-release fertilizer for resin coated bagasse and preparation thereof

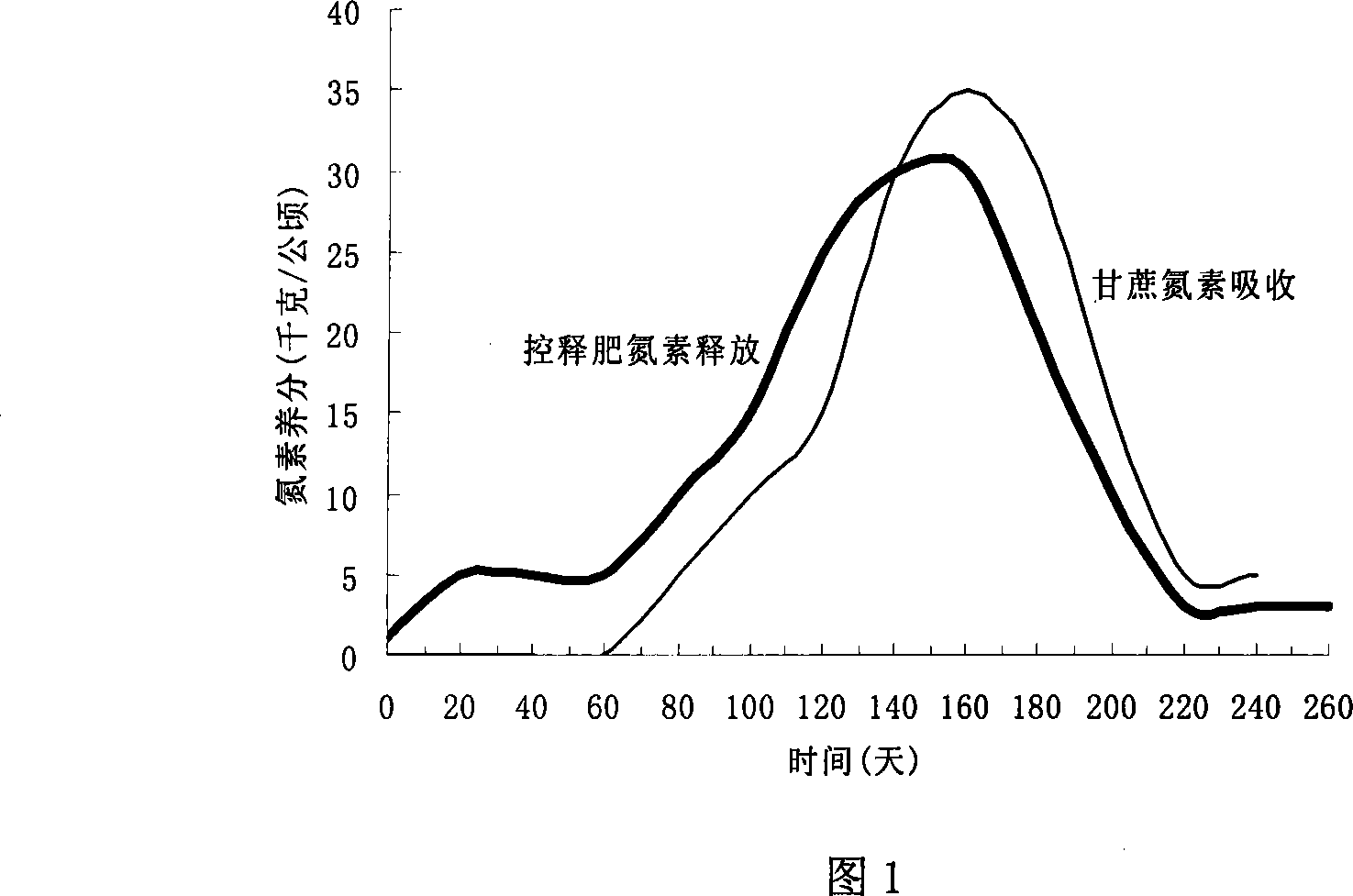

A technology for controlled-release fertilizer and sugarcane, applied in fertilization methods, applications, nitrogen fertilizers, etc., can solve the problems of aggravating the fixation of nutrient ions in the soil, losing the effectiveness of sugarcane, and reducing the utilization rate of fertilizers, so as to reduce soil water evaporation and improve The effect of fertilizer utilization rate and water utilization rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Controlled release fertilizer special for sugarcane, total nutrient: nitrogen, phosphorus pentoxide, potassium oxide content are respectively 19%, 10%, 19%, all are percentage by mass. The raw material components are as follows:

[0048] 6% thermoplastic resin coated potassium nitrate 140kg

[0049] 7% thermoplastic resin coated potassium nitrate 140kg

[0050] 5% thermoplastic resin coated ammonium phosphate 35kg

[0051] 4% thermoplastic resin coated urea 50kg

[0052] 5% thermoplastic resin coated urea 60kg

[0053] 6% thermoplastic resin coated urea 70kg

[0054]8% thermoplastic resin coated urea 35kg

[0055] Potassium sulfate compound fertilizer 465kg

[0057] The preparation method is that the above-mentioned raw materials are put into a blender and stirred for 5-10 minutes, and fully mixed to obtain the product. Then the mixed fertilizer is sent to the metering and packaging machine for metering and packaging.

Embodiment 2

[0058] Embodiment 2: special controlled-release fertilizer for sugarcane, total nutrient: nitrogen, phosphorus pentoxide, potassium oxide content are respectively 17%, 10%, 21%, all are percentage by mass. The raw material components are as follows:

[0059] 6% thermoplastic resin coated potassium nitrate 165kg

[0060] 7% thermoplastic resin coated potassium nitrate 165kg

[0061] 5% thermoplastic resin coated ammonium phosphate 35kg

[0062] 4% thermoplastic resin coated urea 30kg

[0063] 5% thermoplastic resin coated urea 50kg

[0064] 6% thermoplastic resin coated urea 60kg

[0065] 8% thermoplastic resin coated urea 25kg

[0066] Potassium sulfate compound fertilizer 465kg

[0067] Zinc sulfate 5kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com