Micro mechanical adjustable microwave band-pass filter

A microwave strip and micro-mechanical technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of low withstand power, difficulty in reducing control power consumption, increase process difficulty and cost, and avoid the use of through holes. , the effect of reducing passband loss and reducing parasitic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

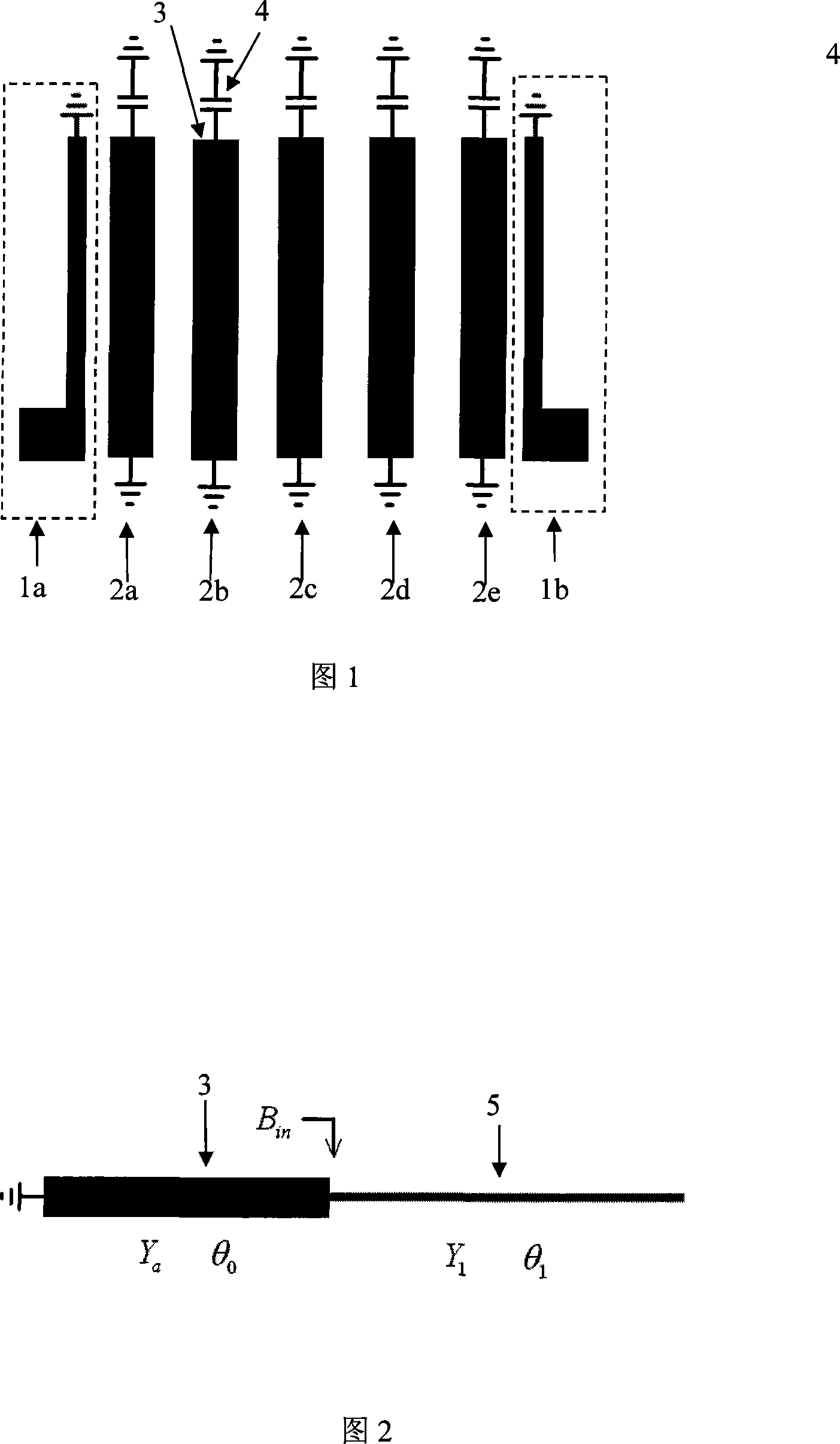

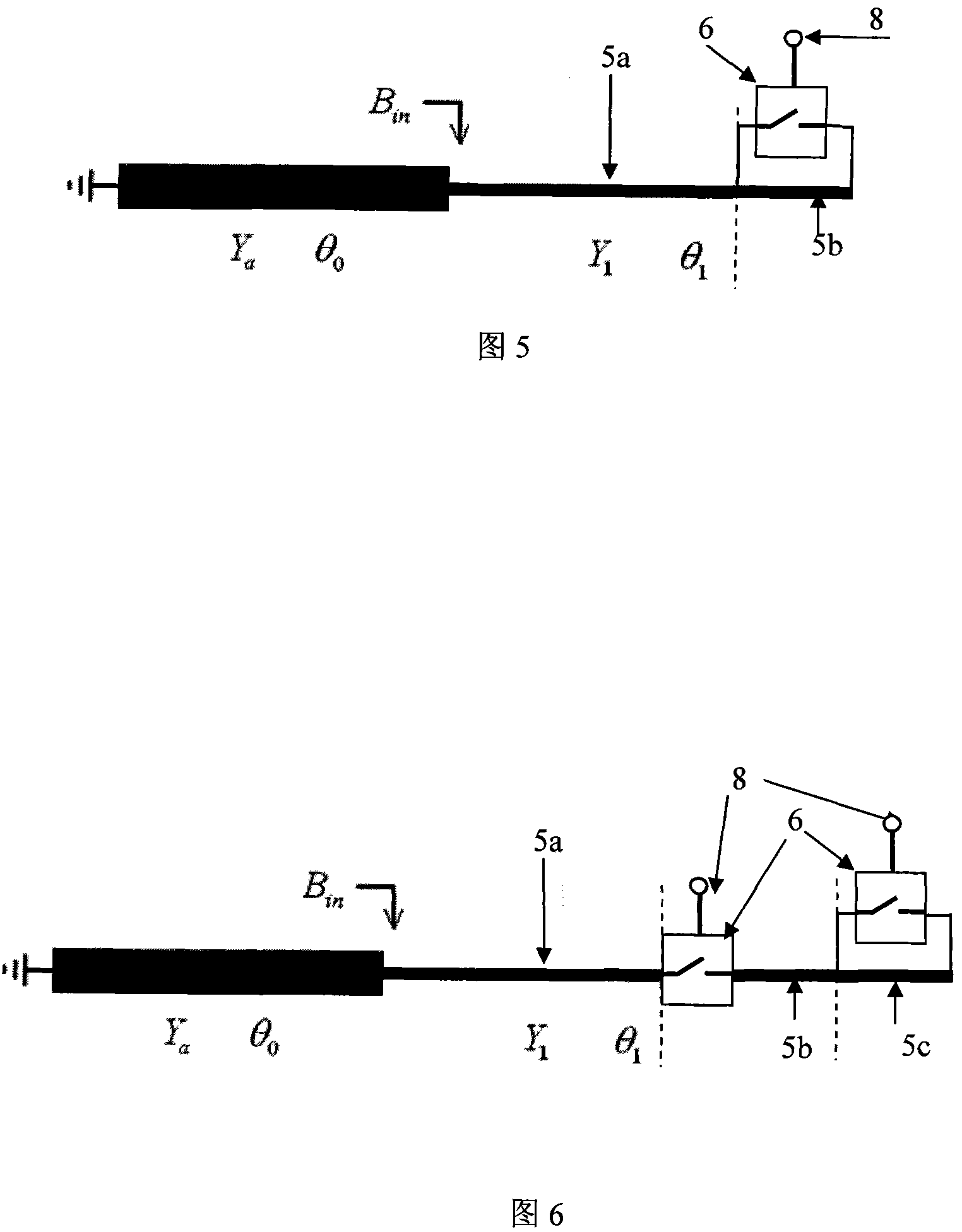

[0037] The micro-mechanical adjustable microwave bandpass filter of the present invention adopts a comb filter structure with adjustable resonance characteristics. The following takes the 5th order filter as an example to illustrate its structure and working principle.

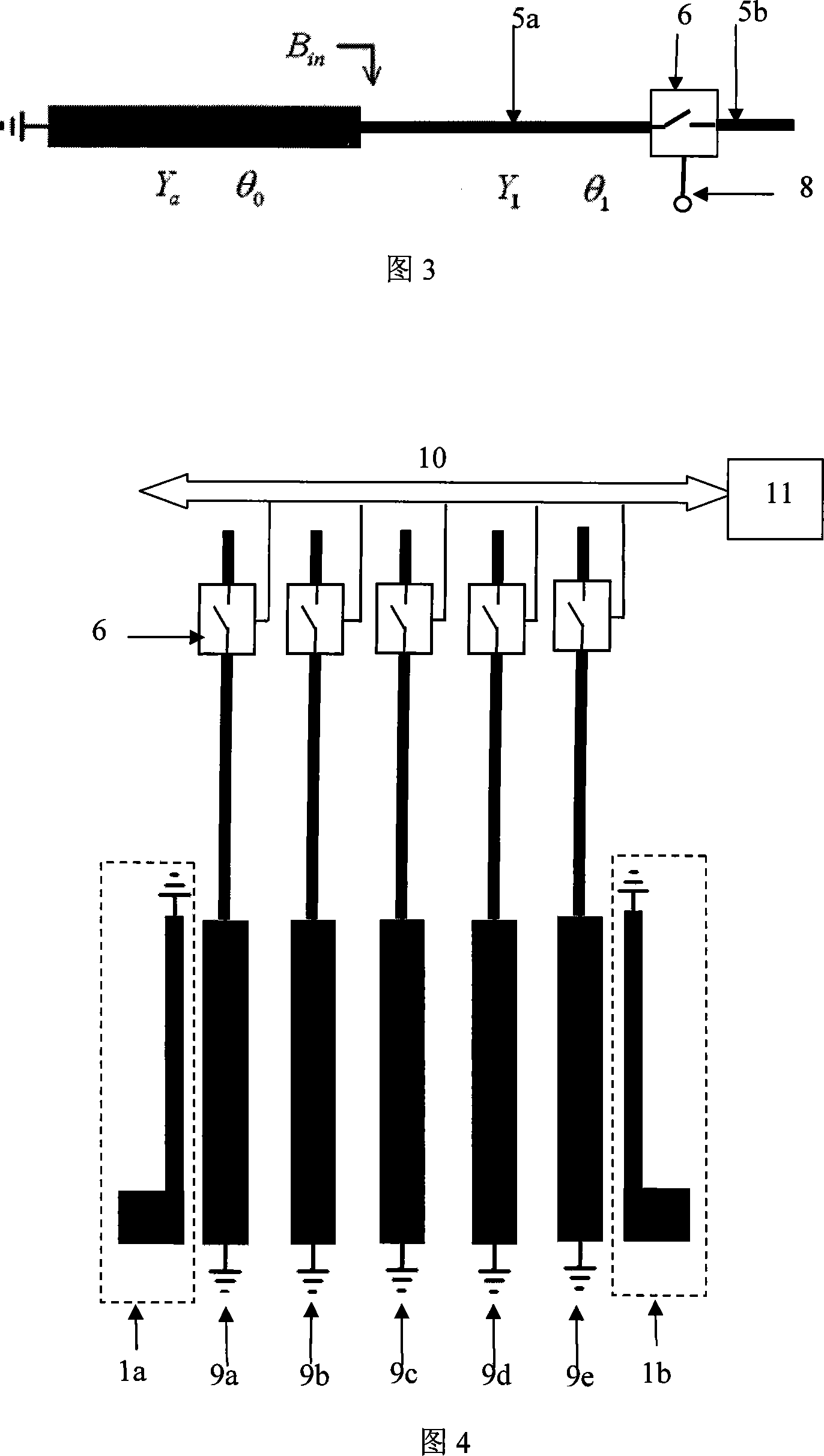

[0038] At first, with reference to Fig. 2, in the resonator unit circuit structure of the present invention, the capacitor 4 in the resonator unit 2a, 2b, 2c, 2d, 2e shown in Fig. and the characteristic impedance are θ 1 and Y 1 ), then the medium-impedance transmission line 3 and the high-impedance transmission line 5 are connected in series to form the S resonator unit structure shown in FIG. The resonant frequency and slope of the resonator unit in a comb filter are key parameters that determine the filter characteristics. Considering the equivalent electrical length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com