Technique for reclaiming byproduct o-chlorobenzoic acid of o-chlorobenzaldehyde production

A technology of o-chlorobenzoic acid and o-chlorobenzaldehyde is applied in the field of recovery technology of by-product o-chlorobenzoic acid in the production of o-chlorobenzaldehyde, and can solve the problems of high recovery cost, environmental pollution, and difficulty in implementation, and reduce the recovery cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

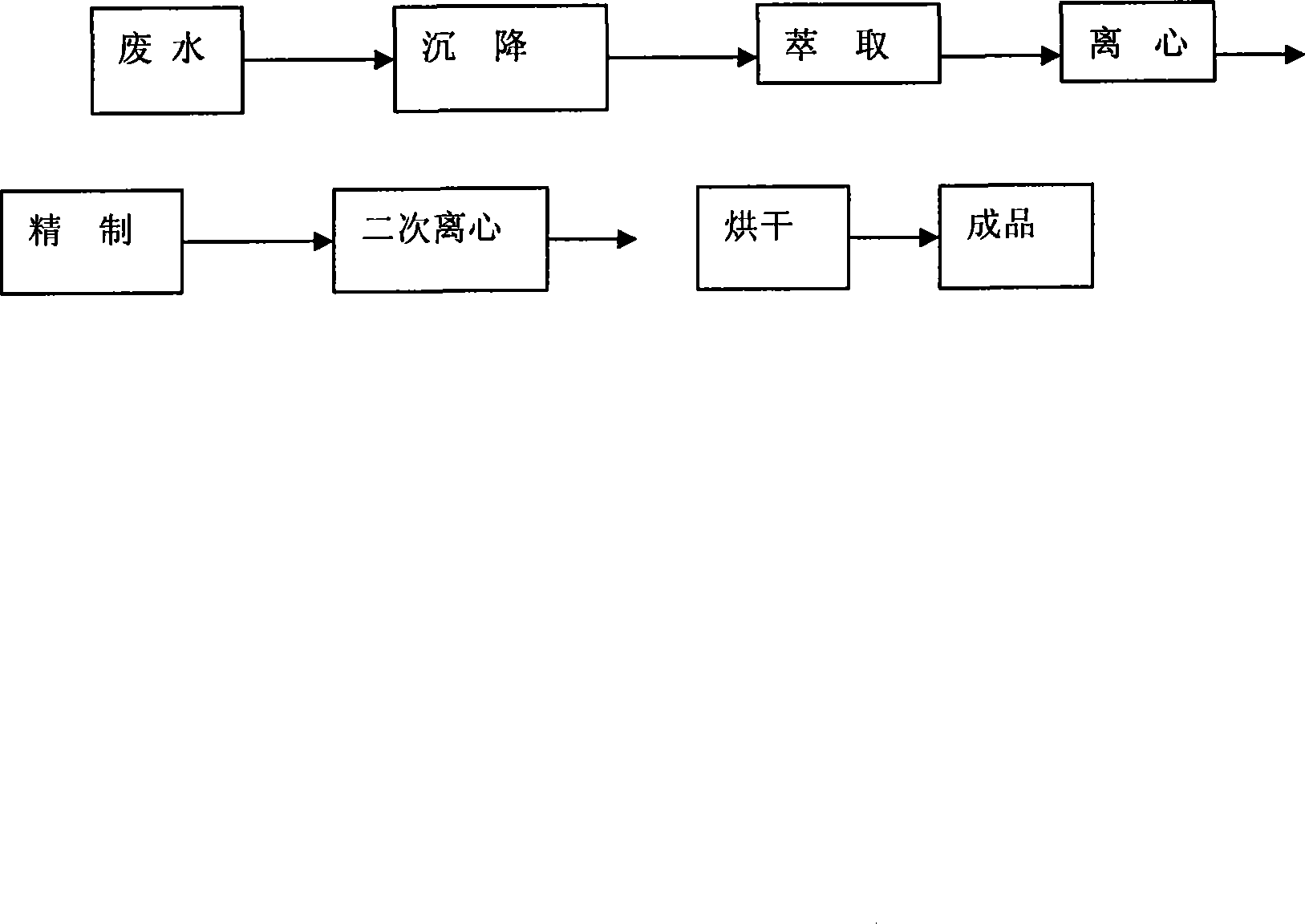

Image

Examples

Embodiment 1

[0016] Process for recovery of by-product o-chlorobenzoic acid in the production of o-chlorobenzaldehyde of the present invention: After the washing water in the production of o-chlorobenzaldehyde is settled for 1h in a 5000L enamel storage tank, a small amount of mechanical impurities in the lower floor are removed, and the water is removed with negative pressure (-0.095MPa) Take 4000L of the solution and pump it into another 5000L enamel reaction kettle, gradually add about 360L of 31% industrial hydrochloric acid dropwise from the industrial hydrochloric acid metering tank (2000L), when the pH value of the solution is 6-7, fully stir for 1-1.5 After h, the o-chlorobenzoic acid in the solution was all separated out, and the solution at that time was an emulsion, and the o-chlorobenzoic acid particles were suspended in the water phase. After centrifugal filtration, 483Kg of o-chlorobenzoic acid filter cake was obtained, and its filter cake contained moisture. About 8%, the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com