Cement clinker calcium sulphoaluminate content measuring method

A technology of cement clinker and calcium sulfoaluminate, which is applied in fluid tightness testing, machine/structural component testing, measuring devices, etc. It can solve the problems of cumbersome experimental steps, environmental pollution, and high sample fineness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

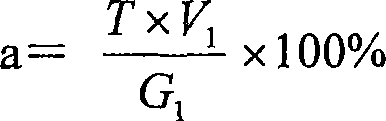

[0062] Adopt the present invention to the content that NJLS cement factory produces Mineral Portland cement clinker The content was determined, which includes the following steps:

[0063] (1) Determination of gypsum decomposition rate:

[0064] (1) Analytical pure CaSO 4 .2H 2 O was heated in a silicon carbide rod furnace at 400°C for 4h, then sealed and placed in a desiccator for later use

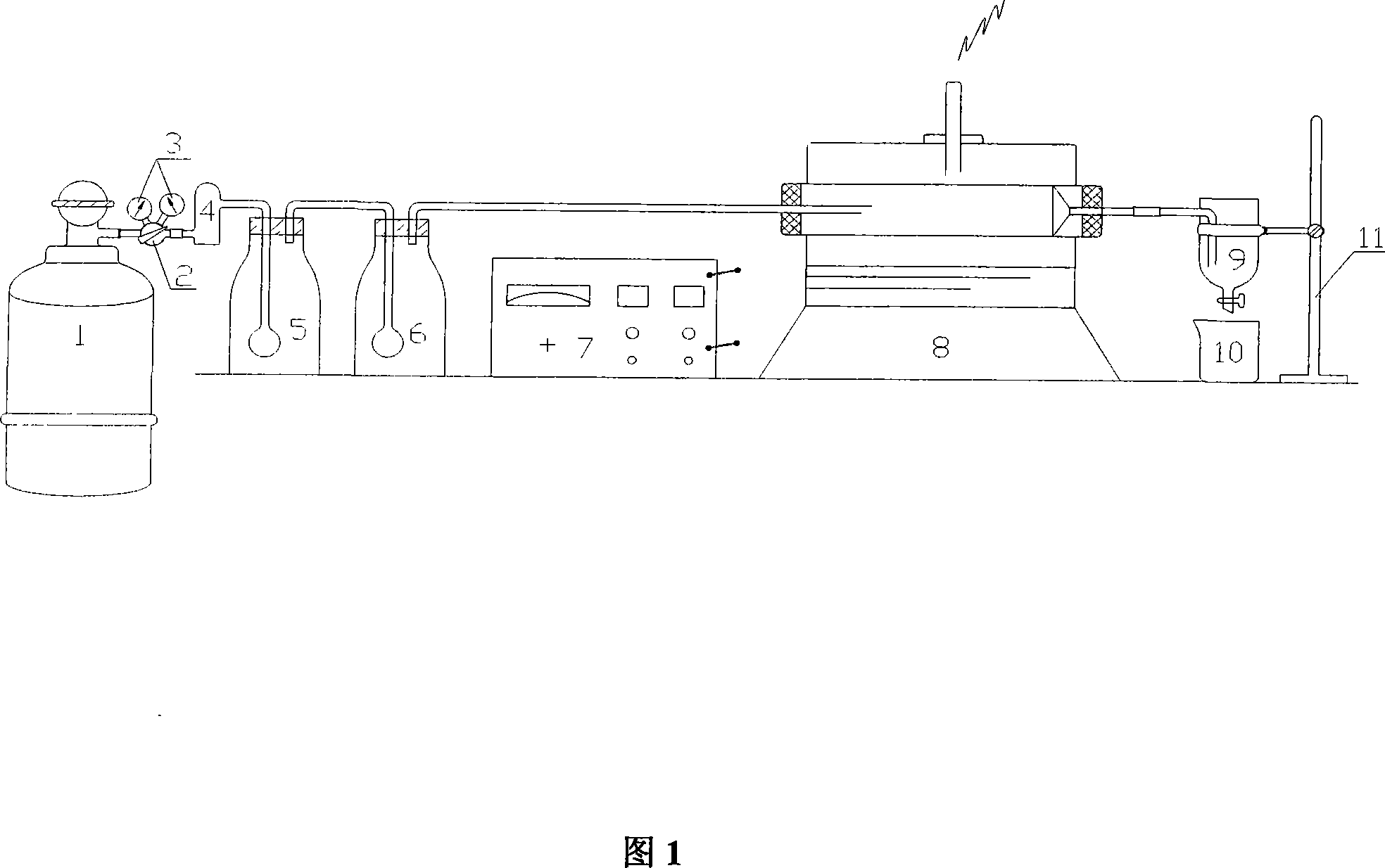

[0065] (2) Connect all devices and check the airtightness of the whole system.

[0066] (3) Turn on the switch of the tubular high-temperature furnace, and set the temperature at 1150°C.

[0067] (4) After the temperature rises to 1150°C, turn on the switch of the nitrogen bottle, adjust the nitrogen pressure reducing valve to make the pressure 0.3MPa, and then adjust the micro rotor flowmeter to control the flow rate to 200ml / min.

[0068] (5) Accurately weigh 0.0209gCaSO 4 , placed in an unglazed porcelain boat.

[0069] (6) Add 250 ml of 0.5% H in the absorption bottle 2 o ...

Embodiment 2

[0107] Adopt the present invention to the content that FJGP cement factory produces Mineral Portland cement clinker The content was determined, which includes the following steps:

[0108] (1) Determination of CaSO 4 decomposition rate

[0109] Measure CaSO according to embodiment 1 method 4 Decomposition rate, a=93.09%

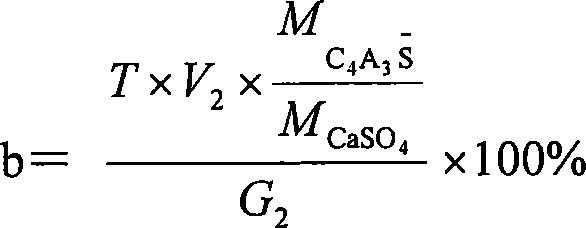

[0110] (2) Determination decomposition rate

[0111] Measure CaSO according to embodiment 1 method 4 Decomposition rate, b=14.19%

[0112] (3) SO in clinker 3 Assay

[0113] SO in the clinker produced by the FJGP factory measured according to the method of embodiment 1 3 Content, the results are shown in Table 2.

[0114] (4) In the clinker Assay

[0115] The determination steps are as follows:

[0116] (1) Connect all devices and check the airtightness of the whole system.

[0117] (2) Turn on the switch of the tube-type high-temperature furnace, and set the temperature at 1150°C.

[0118] (3) After the temperature rises to 1150°C, turn o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com