Tinted glass produced by using chromium-containing waste slag and method for producing the same

A technology for chromium waste residue and glass, which is applied to the color glass prepared by using chromium-containing waste residue and the field of preparation thereof, can solve the problems of environmental pollution, cannot completely seal the chromium residue particles, and cannot be too high, and achieves the solution of environmental pollution problems and good architectural decoration. effect, the effect of lowering the melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

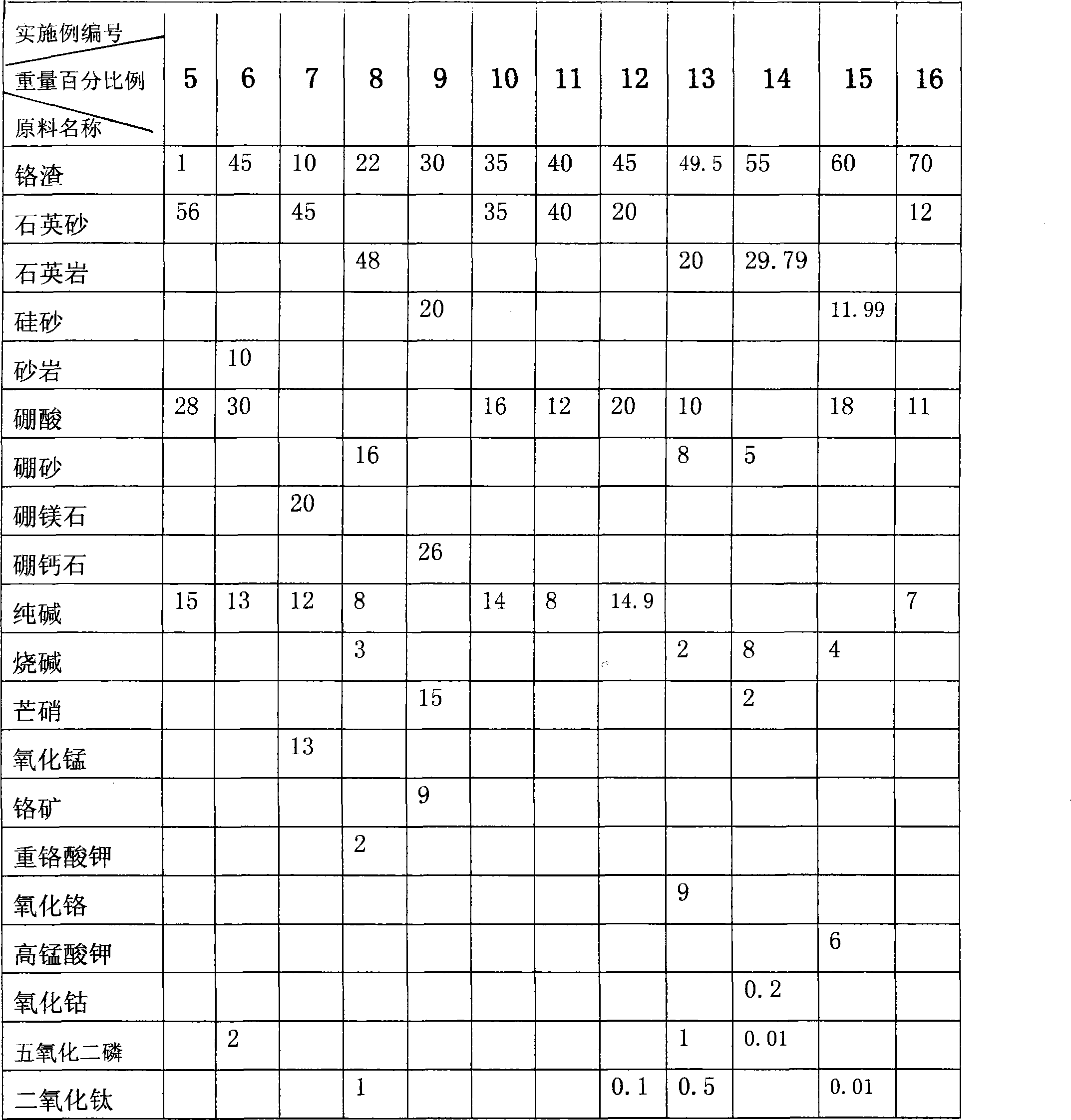

Examples

Embodiment 1

[0039] A method for preparing colored glass prepared from chromium-containing waste residue,

[0040] The process is: preparation of batch materials → glass melting → crystallization treatment → rapid cooling → Venus dilution → glass forming → glass annealing;

[0041] Its main specific steps are as follows:

[0042] a. Preparation of batch materials: 30% chrome slag, SiO 2 30% of quartz sand with a weight percentage of 95%, 20% of boric acid, 15% of alkali, 4.9% of chrome sand, and 0.1% of titanium dioxide. The raw material composition and weight percentage take each component and mix them into a batch;

[0043] b. Glass melting: melt the batch material in a melting furnace at a temperature of 1400-1440°C for 2 hours to obtain a uniform colored glass liquid;

[0044] c. Crystallization treatment: heat the prepared molten glass at a temperature of 1200-1250°C for 1 hour to obtain molten glass containing "Venus"; the size of the Venus is 0.3-1mm;

[0045] d. Rapid cooling: p...

Embodiment 2

[0051] A method for preparing colored glass prepared from waste slag containing chromium, mainly consists of the following steps:

[0052] a. Preparation of batch materials: according to 39.8% chromium slag, SiO 2 35% of quartz sand, 15% of boric acid, 10% of soda ash, 0.2% of cobalt oxide and the weight percentage are not less than 95% of the raw material composition and weight percentage. Take each component and mix it into a batch;

[0053] b. Glass melting: melt the batch material in a melting furnace at a temperature of 1400-1440°C for 2 hours to obtain a uniform colored glass liquid;

[0054] d. Rapid cooling: put the prepared colored glass liquid into cooling water for rapid cooling to obtain small pieces of colored glass;

[0055] e, coloring and dilution: at a temperature of 1250-1270 ° C, the colored glass fritters prepared are dropped into the colorless glass liquid (the colorless glass liquid in the prior art) for 20 minutes according to about 15% glass;

[0056]...

Embodiment 3

[0060] A method for preparing colored glass prepared from waste slag containing chromium, mainly consists of the following steps:

[0061] a. Preparation of batch materials: 50% chrome slag, SiO 2 The raw material composition and weight percent example of 95% quartz sand, 25% boric acid, 15% boric acid, and 10% soda ash are taken by weight and mixed to form a batch;

[0062] b. Glass melting: melt the batch material in a melting furnace at a temperature of 1400±20°C for 2 hours to obtain a uniform colored glass liquid;

[0063] f. Glass forming: the glass is formed into the desired shape by pressing, which is the same as the prior art;

[0064] g. Glass annealing: cooling the molded color glass including Venus glass to room temperature according to the set temperature system to obtain glass products, which is the same as the prior art.

[0065] The glass prepared by the method has no calculus, air bubbles, etc., the color is dark green, and the light transmittance of the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com