Composite bacteria leaven and preparation method thereof

A technology of compound strain and starter, applied in biochemical equipment and methods, microorganism-based methods, bacteria, etc., can solve problems such as difficult industrialization, and achieve the effects of stable performance, good curative effect, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

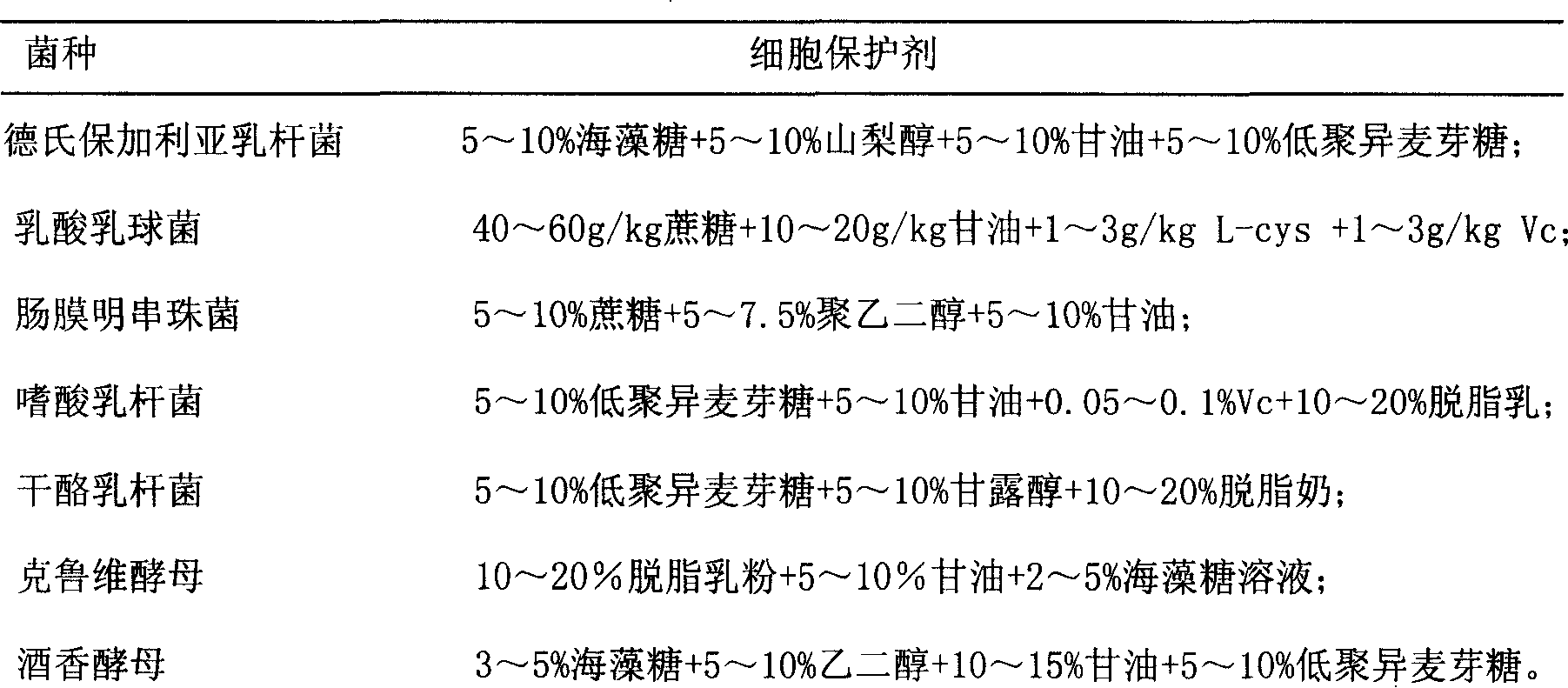

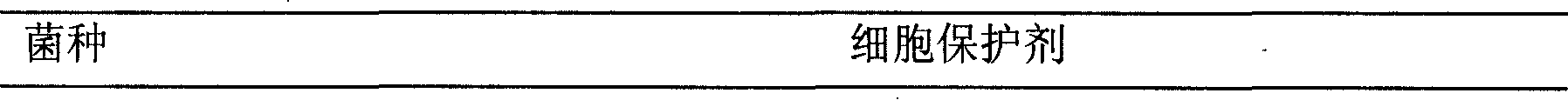

Method used

Image

Examples

Embodiment 1

[0024] Lactobacillus germanitis subsp. bulgaricus; Lactococcus lactis; Leuconostoc enterococci; Lactobacillus acidophilus; Lactobacillus casei; Density culture, the enrichment culture conditions of each bacteria are as follows: Lactobacillus delbrueckii subsp. bulgaricus: use 12% skimmed milk + proteolytic enzyme as the optimized medium, Lactobacillus delbrueckii subsp. Medium, pH value 6.5, stirring speed 250rpm, continuous culture at 30°C without ventilation for 6 hours, adding proliferation factor 5% wort + 3% yeast powder + 10% tomato juice, the feeding amount is 20% of the medium, continue After culturing for 6 hours, the same volume of optimized medium was added, and after culturing for another 6 hours, the fermentation broth was collected. Lactococcus lactis: use 12% skimmed milk + proteolytic enzyme as the optimized medium, inoculate it into the optimized medium at an amount of 5%, control the pH value to 6.0, culture at 32°C, and stir at 250rpm for 6 hours without ven...

Embodiment 2

[0027] Lactobacillus delbrueckii subsp. bulgaricus; Lactococcus lactis; Leuconostoc enterococci; Lactobacillus acidophilus; Lactobacillus casei; Density culture, the enrichment culture conditions of each bacteria are as follows: Lactobacillus delbrueckii subsp. bulgaricus: use 12% skimmed milk + proteolytic enzyme as the optimized medium, Lactobacillus delbrueckii subsp. Medium, pH value 6.5, stirring speed 250rpm, continuous culture at 30°C without ventilation for 4 hours, adding proliferation factor 3% wort + 5% yeast powder + 10% tomato juice, the feeding amount is 15% of the medium, continue After culturing for 4 hours, the same volume of optimized medium was added, and after culturing for another 8 hours, the fermentation broth was collected. Lactococcus lactis: use 12% skimmed milk + proteolytic enzyme as the optimized medium, inoculate it into the optimized medium at an amount of 5%, control the pH value to 6.0, cultivate at 32°C, and stir at 250rpm for 4 hours without ...

Embodiment 3

[0030] Lactobacillus delbrueckii subsp. bulgaricus; Lactococcus lactis; Leuconostoc enterococci; Lactobacillus acidophilus; Lactobacillus casei; Density culture, the enrichment culture conditions of each bacteria are as follows: Lactobacillus delbrueckii subsp. bulgaricus: use 12% skimmed milk + proteolytic enzyme as the optimized medium, Lactobacillus delbrueckii subsp. Medium, pH value 6.5, stirring speed 200rpm, continuous culture at 30°C without ventilation for 6 hours, adding proliferation factor 3.5% wort juice + 3.5% yeast powder + 10% tomato juice, the feeding amount is 15% of the medium, continue After culturing for 6 hours, the same volume of optimized medium was added, and after culturing for another 6 hours, the fermentation broth was collected. Lactococcus lactis: use 12% skimmed milk + proteolytic enzyme as the optimized medium, inoculate it into the optimized medium at an amount of 3%, control the pH value to 6.0, culture at 32°C, and stir at 200rpm for 6 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com