Method for preparing oil smoke absorbing material by microwave

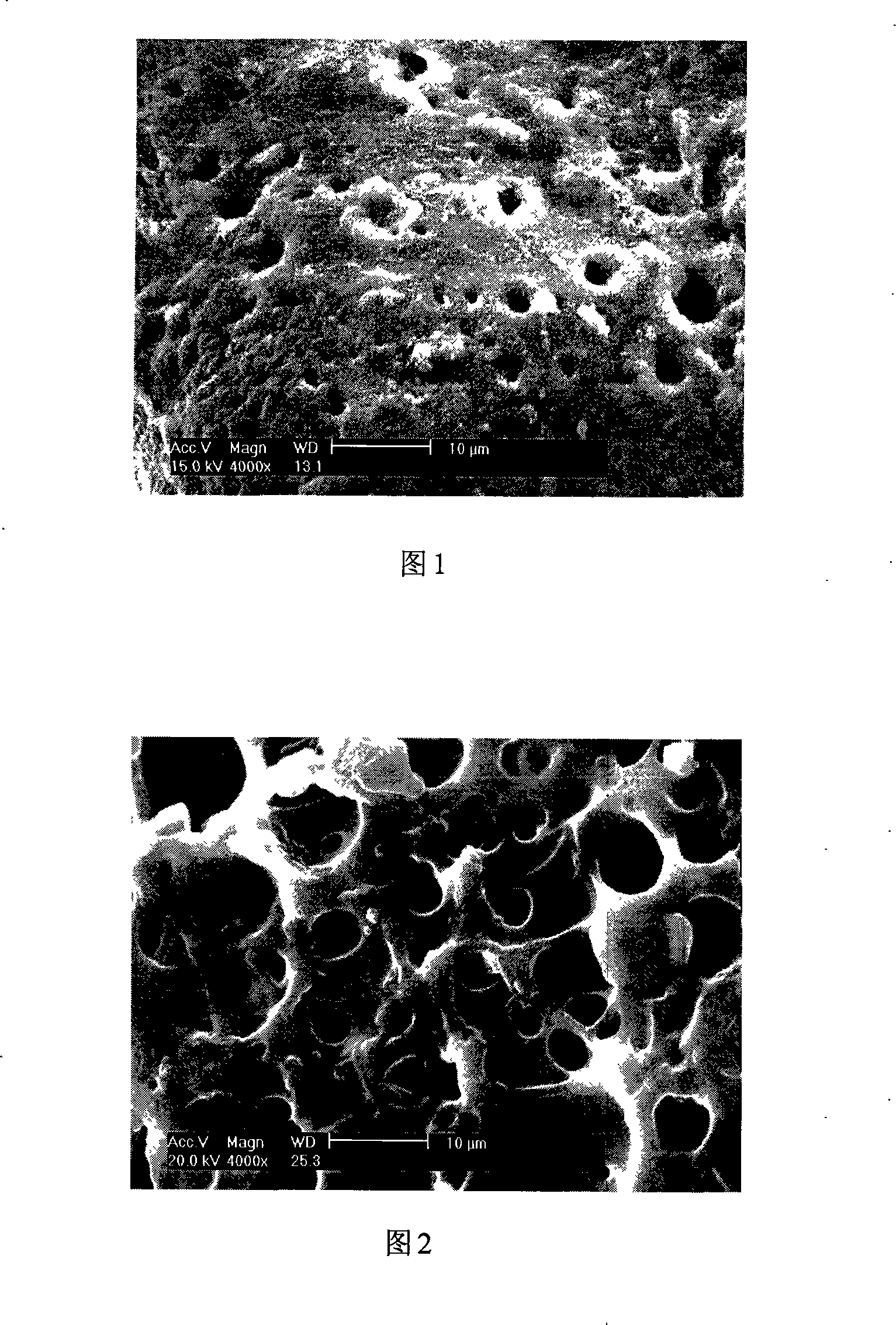

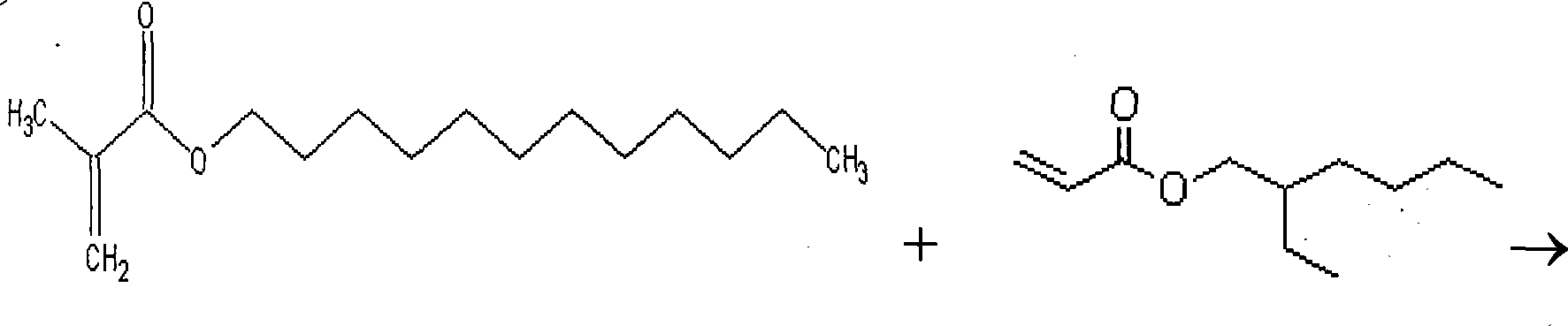

A technology for absorbing oil fume and microwave radiation, which is applied in the field of preparing oil fume absorbing materials by microwave, can solve the problems of poor gas-phase oil fume adsorption effect and long time, and achieve the effects of saving synthesis time, developing pores and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

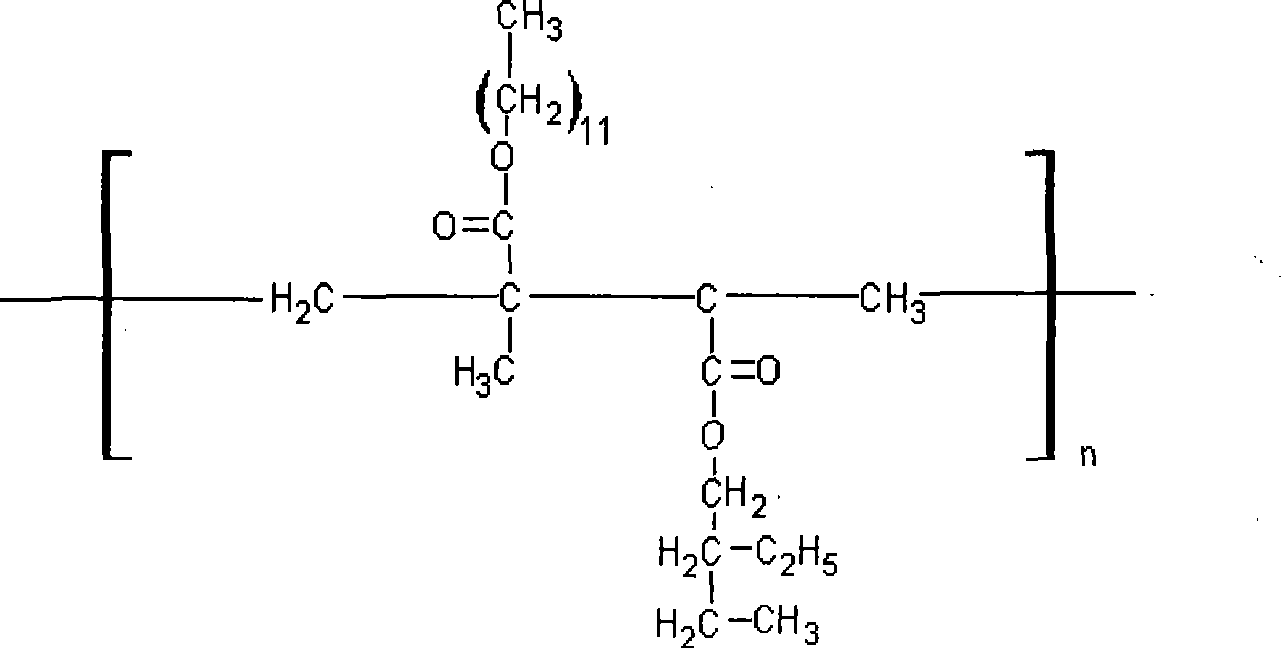

[0022] Embodiment 1: The method for preparing oil-absorbing fume material by using microwave radiation in this embodiment includes the following steps:

[0023] (1) Add 10g of water, 0.04g of gelatin as a dispersant, 0.02g of BPO (benzoyl peroxide) as an initiator, 0.2g of 0.5% divinylbenzene as a crosslinking agent, and 14g of formaldehyde in a flask. Lauryl acrylate and 6g of 2-ethylhexyl acrylate were used as comonomers, stirred and heated to 50°C to dissolve;

[0024] (2) Add a stirring magnet to the mixed solution obtained in (1), adjust the stirring speed to a medium speed, stir the solution on the magnetic stirrer for 10 minutes and then pour the solution into an XP1500 polytetrafluoroethylene microwave special reaction tank (100mL) , and then placed in a microwave reaction chamber to react for 3 hours at 80°C and the power per unit volume of the microwave radiation power is 600W / L;

[0025] (3) The product obtained in (2) was washed with deionized water, filtered, and...

Embodiment 2

[0035] The method for preparing the oil-absorbing material by using microwave radiation in this embodiment includes the following steps:

[0036] (1) Add 120g of water, 0.4g hydroxypropyl methylcellulose as a dispersant, 0.4gBPO (benzoyl peroxide) as an initiator, and 0.1g of 0.1% N, N-sub Methylbisacrylamide is used as a crosslinking agent, 10g of methyl methacrylate and 10g of butyl methacrylate are used as comonomers, and the temperature is stirred to 60°C to dissolve;

[0037] (2) Add a stirring magnet to the mixed solution obtained in (1), adjust the stirring speed to a medium speed, stir the solution on the magnetic stirrer for 10 minutes and then pour the solution into an XP1500 polytetrafluoroethylene microwave special reaction tank (100mL) , and then put it into a microwave reaction chamber and react for 1h under the condition of 50°C and the power per unit volume of the microwave radiation power is 200W / L;

[0038] (3) The product obtained in (2) was washed with dei...

Embodiment 3

[0045] Embodiment 3: First synthesize isobutyl acrylate, the specific method is as follows: Weigh a certain amount of cation exchange resin and pour it into a flask, acrylic acid and isobutanol each take 50mL and add them to a 500mL four-neck flask in an equimolar ratio, and add A small amount of inhibitor. The whole reaction process was stirred under reduced pressure, and the crude product of isobutyl acrylate was obtained after reacting for about 2 hours. The product was washed repeatedly with 5% NaOH solution, and finally washed with deionized water until neutral.

[0046] Using microwave radiation to prepare the oil-absorbing material, including the following steps:

[0047] (1) Add 100g of water, 1g of polyvinyl alcohol as a dispersant, 1g of benzoyl oxide as an initiator, 0.1g of 1% 1,4-butanediol as a crosslinking agent, 100g of acrylic acid in a flask Isobutyl fat is used as a comonomer, stir and heat up to 95°C to dissolve;

[0048] (2) Add a stirring magnet to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com