Metallic surface passivating film carrier density detection method

A carrier density and metal surface technology, applied in the direction of current density measurement, measuring devices, instruments, etc., can solve the problems of loss of protection ability, carrier accumulation, elimination, etc., and achieve the effect of monitorability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, test electrodes are prepared. The base material of the test electrode is a Φ10mm 304 stainless steel rod. After being sealed with epoxy resin, the working surface is polished with 05# metallographic sandpaper, washed with absolute ethanol and acetone in sequence, dried, and placed in a desiccator for later use.

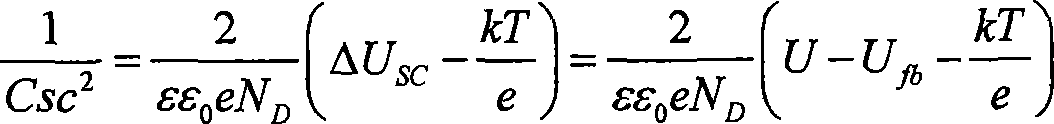

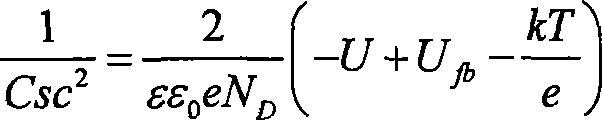

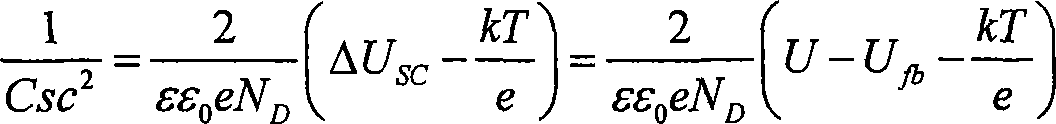

[0029] Then soak the electrode to be tested in 5% Na prepared by analytical grade reagents and deionized water 2 SO 4 Solution, with saturated calomel electrode as reference electrode, platinum electrode as counter electrode, carry out potential-capacitance test on the CHI660C electrochemical workstation controlled by computer, and then draw the data Mott-Schottky relationship diagram; due to the stainless steel rod 5%Na 2 SO 4 The solution shows n-type semiconductor characteristics, so according to the Mott-Schottky relationship:

[0030] 1 Csc 2 = 2 ...

Embodiment 2

[0032] Embodiment 2: The method of this embodiment is basically the same as that of Embodiment 1, and the electrode to be tested is a 20# carbon steel rod with a diameter of 10 mm. The measured Mott-Schottky relationship diagram; see Table 1 for the measured carrier data when the soaking time is 10min, 1h, 3h, 6h, and 11h.

Embodiment 3

[0033] Embodiment 3: The method of this embodiment is basically the same as that of Embodiment 1, and the electrode to be tested is an H62 brass rod with a diameter of 10 mm. The measured Mott-Schottky relationship diagram; see Table 1 for the measured carrier data when the soaking time is 10min, 1h, 3h, 6h, and 11h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com