Raw material prescription with hydrophile ion interchange and inphase opposition ion interchange separation mode chromatographic column and preparation

A technology of ion exchange and reversed-phase ions, applied in the field of electrochromatography, can solve the problems of brittle columns, high column packing skills, and low sample capacity, and achieve a wide range of separation objects, high space utilization, and fast mass transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

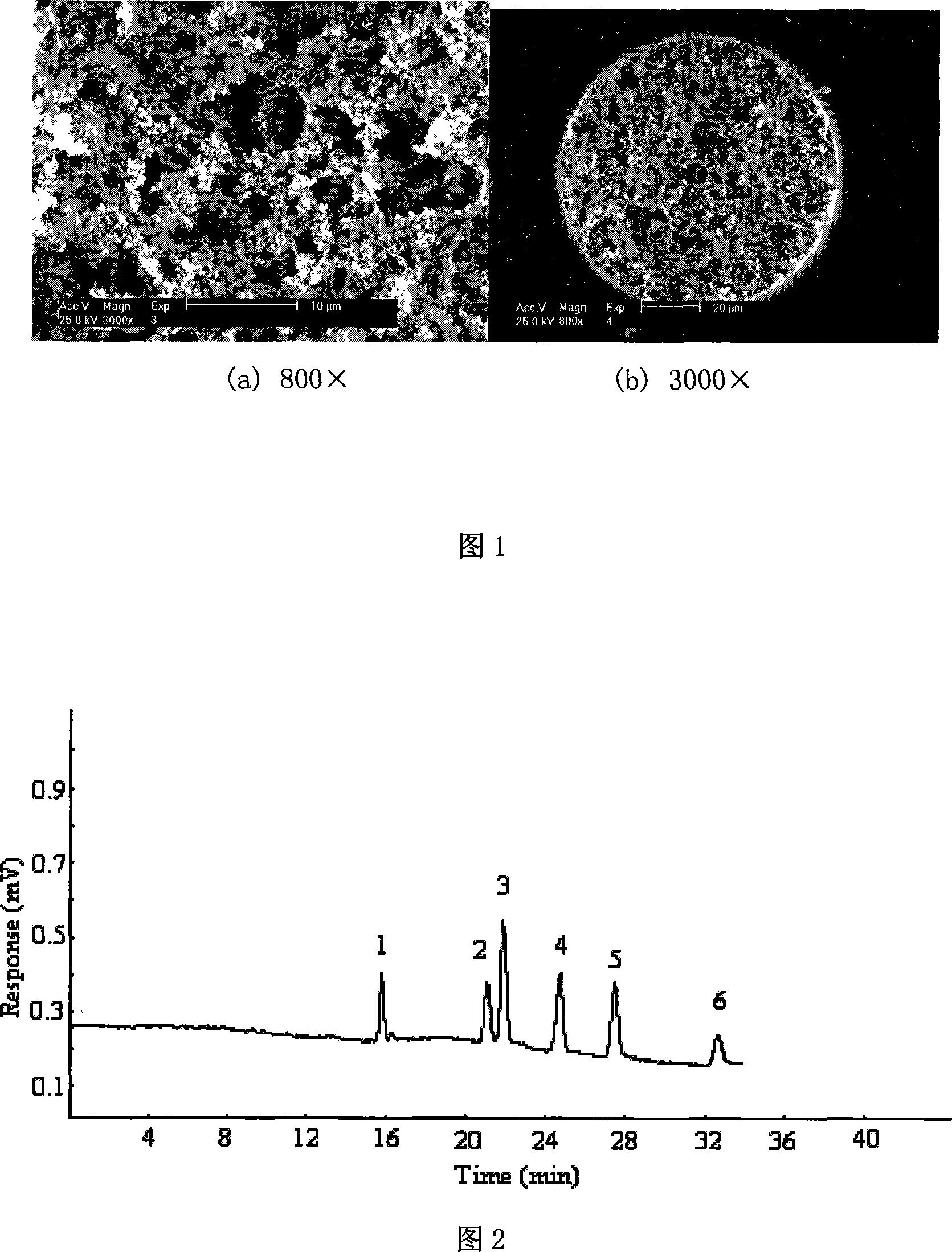

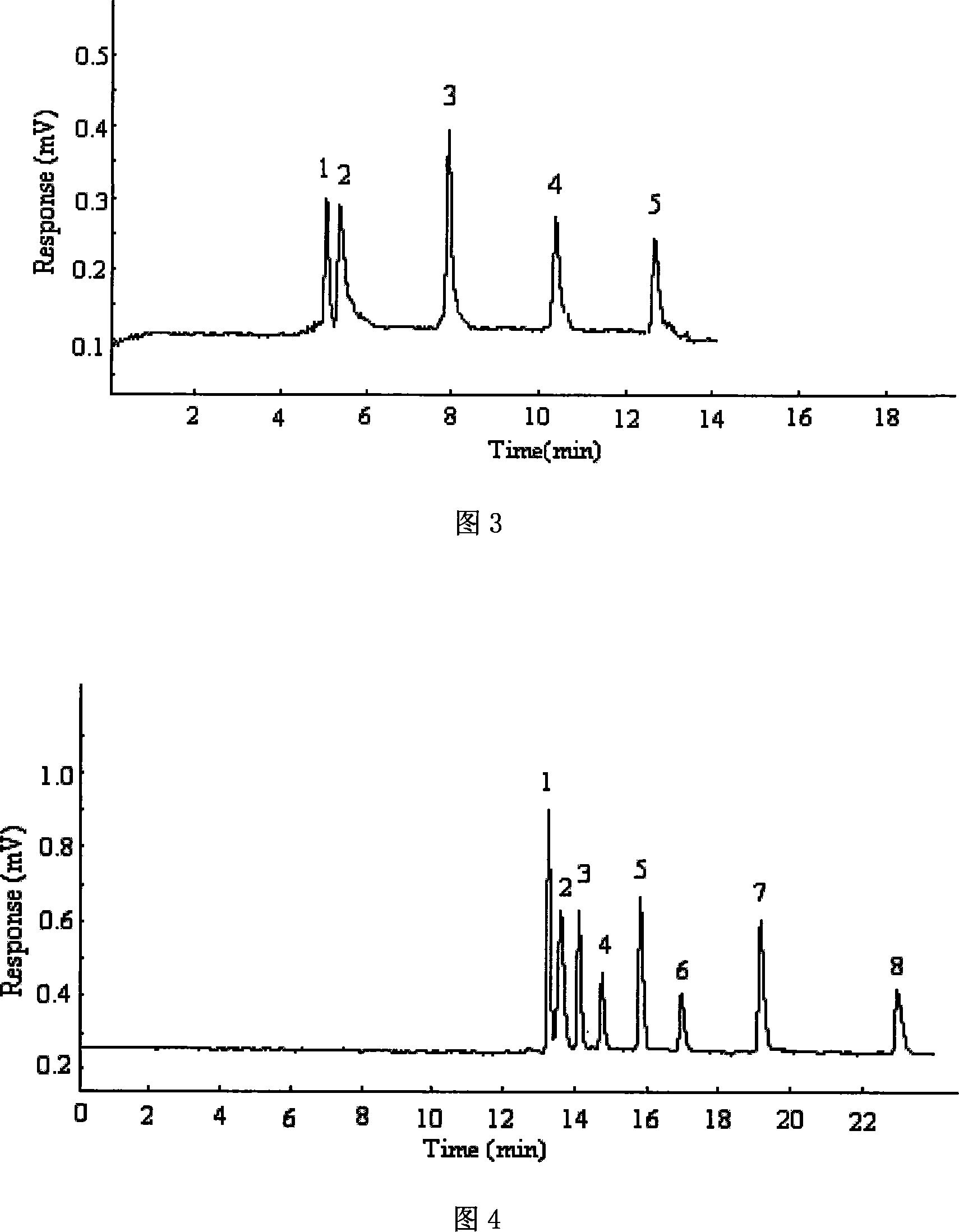

Image

Examples

Embodiment 1

[0022] 1. Pretreatment of capillaries

[0023] Rinse the empty capillary column with 0.1mol / L HCl solution for 30 minutes, then rinse it with deionized water for 10 minutes, then rinse it with 0.1mol / L NaOH for 4 hours, then rinse it with methanol for 15 minutes, and dry it with nitrogen gas for use;

[0024] 2. Silanization of the Capillary Wall

[0025] Inject a mixture of methanol and methacryloxypropyltrimethoxysilane with a volume ratio of 1:1 into the capillary treated in step 1, and react at 60°C for 24 hours to bond a layer of alkenyl on the capillary wall. The silanized substance; then rinse with methanol for 15 minutes; dry the capillary with nitrogen at 70°C;

[0026] 3. In-column synthesis

[0027] Glycidyl methacrylate, ethylene glycol dimethacrylate, propyl methacrylate sulfonate, N,N-dimethylformamide and 1,4-butanediol are respectively 29.6% by weight , 10.0%, 0.4%, 12.0%, 48.0%, the amount of added initiator azobisisobutyronitrile (AIBN) is 0.3% of the tota...

Embodiment 2

[0030]Glycidyl methacrylate, ethylene glycol dimethacrylate, methacryloyloxyethyltrimethylammonium chloride, N,N-dimethylformamide and 1,4-butanediol were weighed The ratios are 22.2%, 7.5%, 0.3%, 14.0%, and 56.0%, respectively, and the amount of added initiator azobisisobutyronitrile (AIBN) is 0.3% of the total amount of matrix monomer and ionic monomer. Mix the raw materials according to the above formula, ultrasonically vibrate the resulting mixture for 15 minutes, blow nitrogen gas for 10 minutes to remove dissolved oxygen in the mixture, then inject the mixture into a silanized capillary, and control a certain length to seal both ends of the capillary And immersed in a 60°C water bath, reacted for 36 hours, after the reaction was completed, rinse the capillary column with methanol to remove the residual reagent in the column; then, fill the capillary column with 1mol / L hydrochloric acid solution, and heat it in a 60°C water bath for 4 hours, and finally wash the capillary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com