Superparamagnetism mesoporous silicon dioxide composite ball and preparing method thereof

A mesoporous silica and superparamagnetic technology, applied in the direction of magnetic properties of silica, silica, inorganic materials, etc., can solve the problems of low saturation magnetization, wide size distribution of silica composite particles, irregular shape, etc. , to achieve the effect of high content of magnetic substances, low equipment requirements, and strong external magnetic field responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

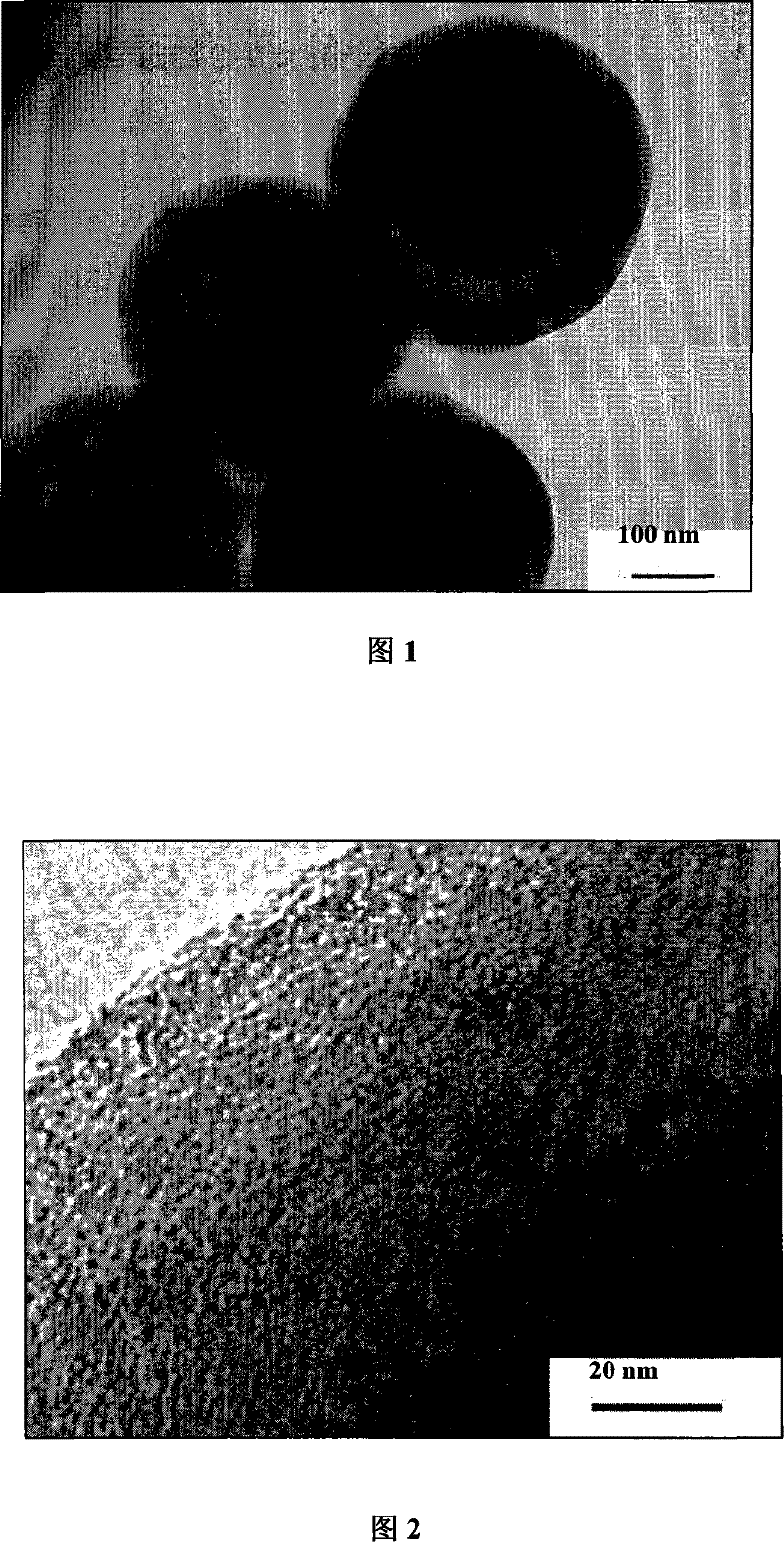

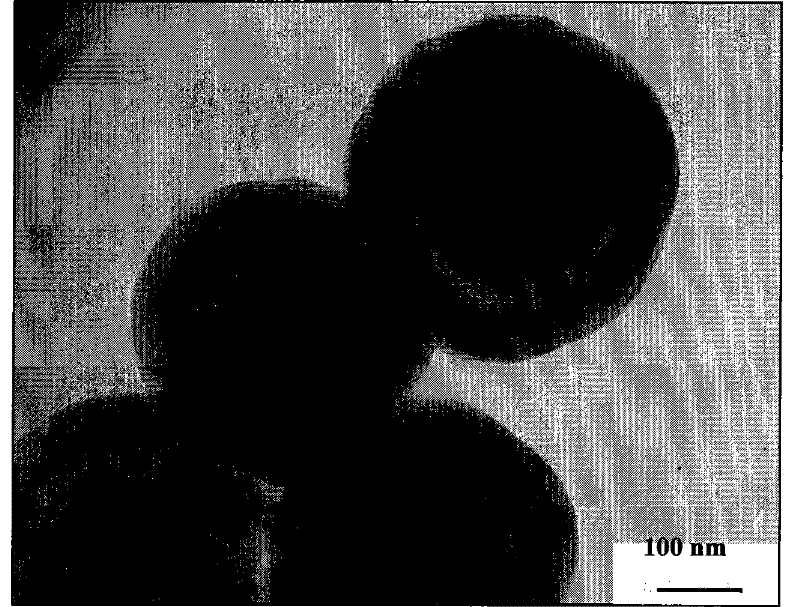

[0023] Example 1: Fe 3 o 4 Preparation of nanoparticles

[0024] Weigh 13.73g of FeCl 3 ·6H 2 O and 5.1 g FeCl 2 4H 2 O, dissolved in 100mL of water that has passed through nitrogen and deoxygenated to obtain a mixed solution. Take 400mL of water in a 1L three-necked bottle to pass through nitrogen to remove oxygen, add 25mL of concentrated ammonia water with a concentration of 25% to 28% by mass, and quickly pour the above iron salt mixed solution into it under vigorous stirring. Reaction 1h. After the reaction is completed, use a 0.4T permanent magnet to separate the black solid from the reaction solution, and wash the obtained solid with high-purity water for 3 to 5 times to obtain Fe with a particle size of 7 to 12 nm. 3 o 4 Nanoparticles.

Embodiment 2

[0025] Example 2: γ-Fe 2 o 3 Preparation of nanoparticles

[0026] Weigh 13.73g of FeCl 3 ·6H 2 O and 5.1 g FeCl 2 4H 2 O, dissolved in 100mL of water that has passed through nitrogen and deoxygenated to obtain a mixed solution. Take 400mL of water in a 1L three-necked bottle to pass through nitrogen to remove oxygen, add 25mL of concentrated ammonia water with a concentration of 25% to 28% by mass, and quickly pour the above iron salt mixed solution into it under vigorous stirring. Reaction 1h. Oxygen was then introduced into the reaction solution for 2 h. After the reaction is completed, use a 0.4T permanent magnet to separate the red solid from the reaction solution, and wash the obtained solid with high-purity water for 3 to 5 times to obtain γ-Fe with a particle size of 7 to 12 nm. 2 o 3 Nanoparticles.

Embodiment 3

[0027] Example 3: CoFe 2 o 4 Preparation of nanoparticles

[0028] Weigh 14g of CoCl 3·6H 2 O and 5.1 g FeCl 2 4H 2 O, dissolved in 100mL of water that has passed through nitrogen and deoxygenated to obtain a mixed solution. Take 400mL of water in a 1L three-necked bottle to pass through nitrogen to remove oxygen, add 25mL of concentrated ammonia water with a concentration of 25% to 28% by mass, quickly pour the above mixed salt solution into it under vigorous stirring, and react at 50°C 1h. After the reaction is completed, use a 0.4T permanent magnet to separate the black solid from the reaction solution, and wash the obtained solid with high-purity water for 3 to 5 times to obtain CoFe with a particle size of 7 to 12 nm. 2 o 4 Nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com