Tungsten bronze structure lead lanthanum niobate titanate high-temperature piezoelectric ceramic and preparation method thereof

A lanthanum niobate titanate, high-temperature piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of poor repeatability of the preparation process, difficulty in mass production, extreme The problems of reducing the chemical yield and other problems, to achieve the effect of simple preparation process, low cost, and reduced dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

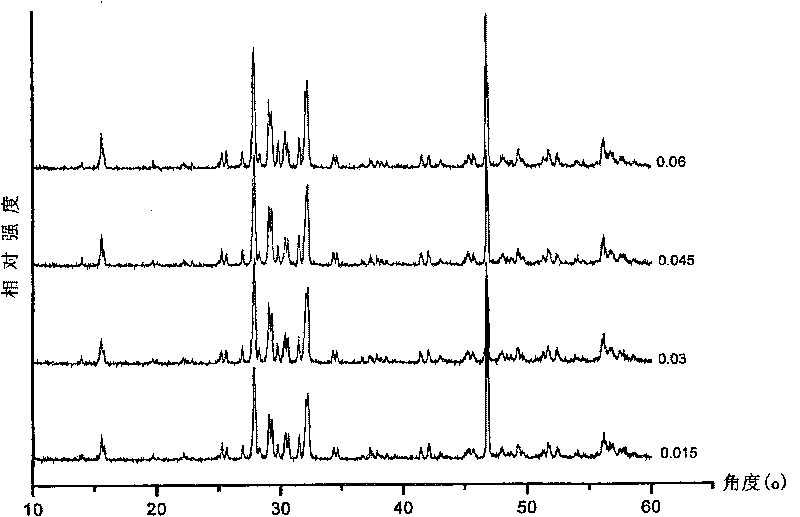

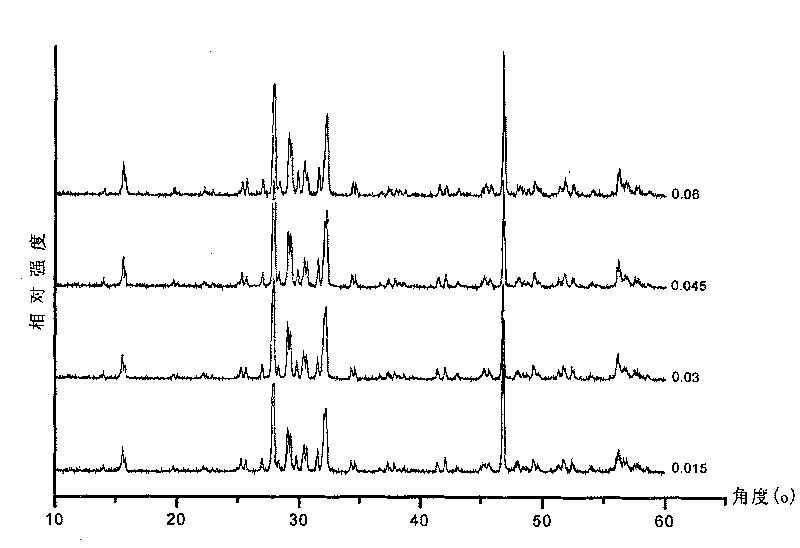

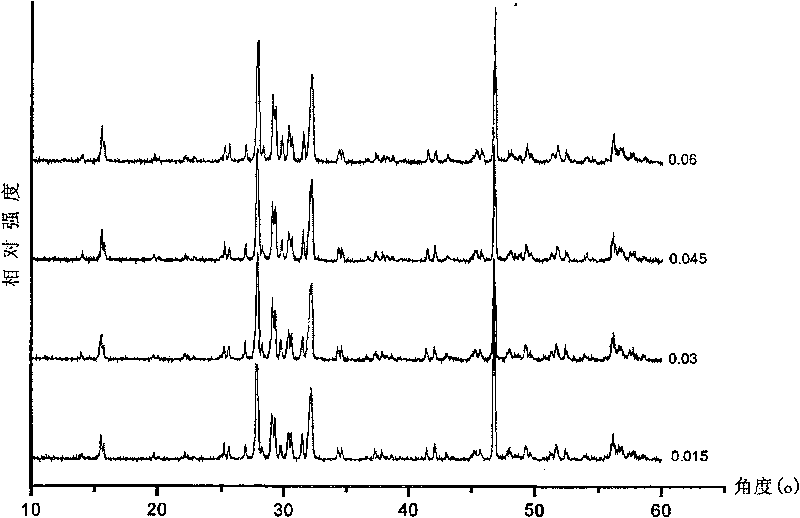

Image

Examples

Embodiment 1

[0037] Take the used raw material 100g of producing product of the present invention as example, when x is 0.045, y is 0.05, use general formula (Pb 0.955 La 0.03 )(Nb 0.95 Ti 0.0625 ) 2 o 6 The expressed raw materials and their weight proportions are:

[0038] PbO 44.36g

[0039] La 2 o 3 1.02g

[0040] Nb 2 o 5 52.55g

[0041] TiO 2 2.07g

[0042] Its preparation method is as follows:

[0043] 1. Ingredients synthesis

[0044] Put above-mentioned raw material in nylon tank, add dehydrated alcohol 200g to be dispersant, zirconia ball 150g is ball milling medium, the diameter of zirconia ball is 3~15mm, promptly raw material: dehydrated alcohol: the weight ratio of zirconia ball is 1:2:1.5, use a ball mill to grind for 17 hours at a speed of 300 rpm, separate the zirconia balls, put the mixture in a drying oven at 80°C, dry it for 5 hours, then put it in a mortar and grind for 25 minu...

Embodiment 2

[0058] Take the used raw material 100g of producing product of the present invention as example, when x is 0.015, y is 0.025, use general formula (Pb 0.985 La 0.01 )(Nb 0.975 Ti 0.03125 ) 2 o 6 Indicated raw materials and their weight ratio:

[0059] PbO 45.27g

[0060] La 2 o 3 0.34g

[0061] Nb 2 o 5 53.36g

[0062] TiO 2 1.03g

[0063] Its preparation method is as follows:

[0064] Put the raw materials into a nylon tank, add 200 g of absolute ethanol as a dispersant, and 150 g of zirconia balls as a ball milling medium. The other steps of this process step are the same as in Example 1. In step 2 of the pre-firing process, the ground material is pressed into a disc with a diameter of 20mm and a thickness of 15mm, placed in an alumina crucible, covered, and kept at 850°C for 4 hours in a muffle furnace. Cool to room temperature and remove from the oven. In step 3 of the...

Embodiment 3

[0066] Take the used raw material 100g of producing product of the present invention as example, when x is 0.06, y is 0.10, use general formula (Pb 0.94 La 0.04 )(Nb 0.9 Ti 0.125 ) 2 o 6 Indicated raw materials and their weight ratio:

[0067] PbO 44.12g

[0068] La 2 o 3 1.37g

[0069] Nb 2 o 5 50.31g

[0070] TiO 2 4.20g

[0071] Its preparation method is as follows:

[0072] Put the raw materials into a nylon tank, add 200 g of absolute ethanol as a dispersant, and 150 g of zirconia balls as a ball milling medium. The other steps of this process step are the same as in Example 1. In step 2 of the pre-firing process, the ground material is pressed into a disc with a diameter of 20 mm and a thickness of 15 mm, placed in an alumina crucible, covered, and kept at 1050 ° C for 2 hours in a muffle furnace. Cool to room temperature and remove from the oven. In ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com