Bacteria cellulose and Hydroxyethyl methacrylate transparency compound material and preparation thereof

A technology of poly(beta-hydroxyethyl methacrylate) and beta-hydroxyethyl methacrylate, which is applied in the field of biomedical materials, can solve the problems of limited application range, poor mechanical properties, reduced transparency, etc., and achieves good biocompatibility , good mechanical properties, high moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Using Acetobacter xylinum as a bioreactor, bacterial cellulose hydrogel film was prepared by fermentation [L.Hong, Y.L.Wang, S.R.Jia, Y.Huang, C.Gao, Y.Z.Wan Hydroxyapatite / bacterial cellulose composites synthesized via a biomimetic route , Materials Letters 60 (2006) 1710-1713.].

[0017] Add 0.2% azobisisobutyronitrile and 0.5% ethylene glycol dimethacrylate to the β-hydroxyethyl methacrylate monomer, and stir at room temperature for 30 minutes to obtain a uniformly mixed solution. Bacterial cellulose membrane (5×1 cm) was immersed in the solution, soaked for 3 days, taken out and put into a polytetrafluoroethylene mold, protected by nitrogen gas, and reacted at 70° C. for 7 hours. After the reaction was finished, the reaction product was taken out and soaked in deionized water for 7 days, and new deionized water was changed every day during the soaking period.

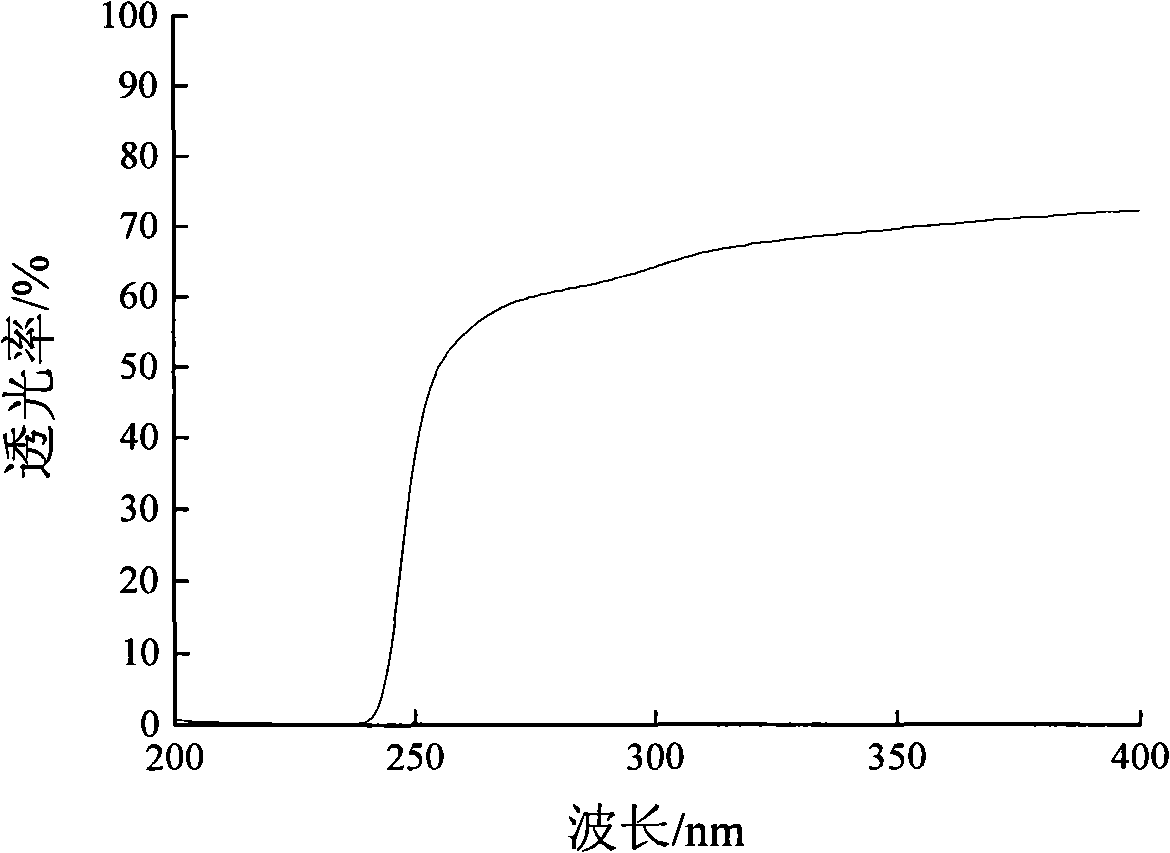

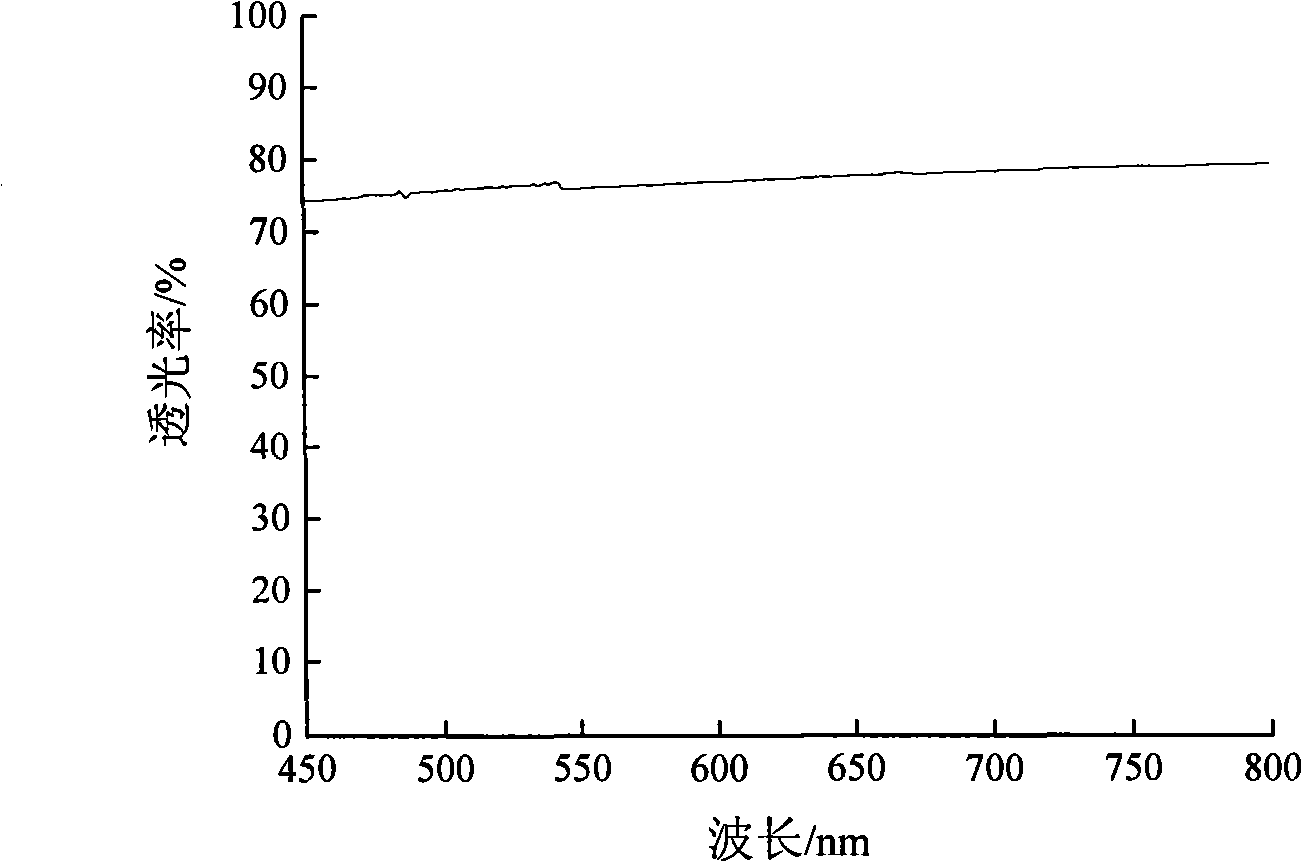

[0018] Wipe off the surface moisture of the obtained product with filter paper, and measure the light tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com