Preparing method of porous carbon electrode of super capacitor with high magnified charge-discharge performance

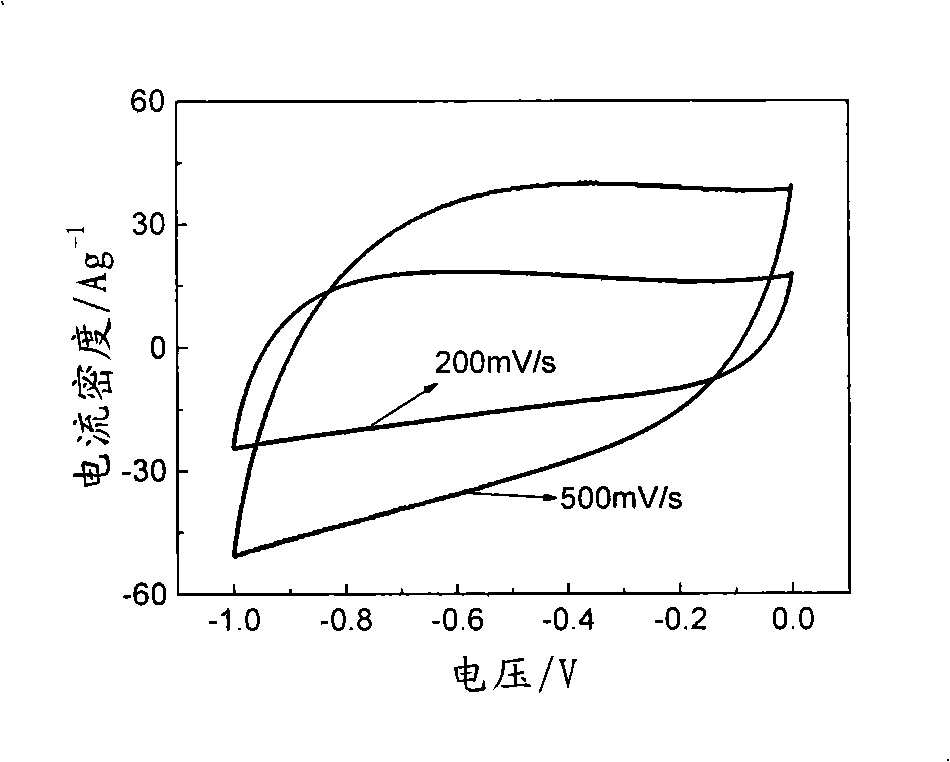

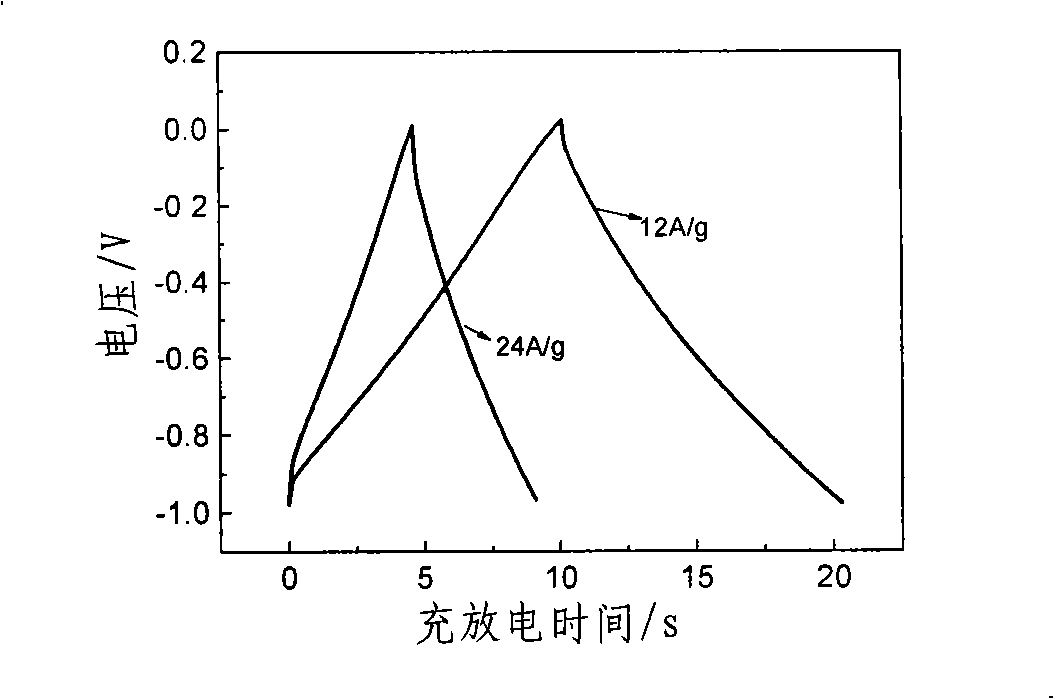

A supercapacitor, charge and discharge performance technology, applied in the field of porous carbon electrode preparation, to achieve the effect of good high rate charge and discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

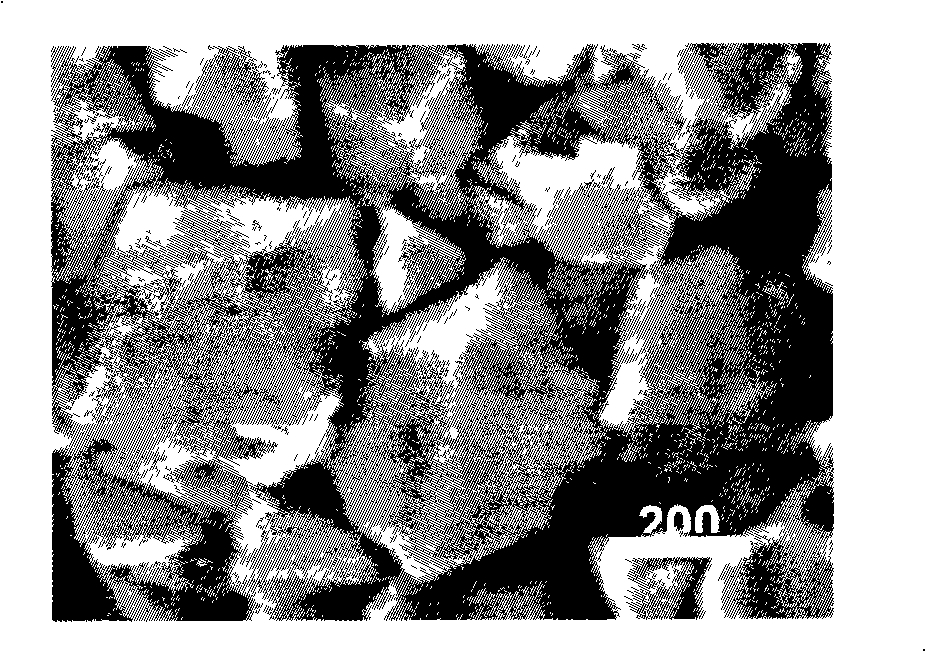

[0017] Add 100mg Y-type zeolite molecular sieve template into the quartz reactor, and pass 99.999% nitrogen at a flow rate of 125ml / min. Use a high-frequency heating device to heat up to 800°C at a heating rate of 100°C / min, and then pass it in at a flow rate of 25ml / min 99.999% high-purity methane gas, constant temperature for 1 hour for chemical vapor deposition, stop feeding methane gas, continue to feed 99.999% nitrogen at a flow rate of 125ml / min, and heat up to 1100°C at a heating rate of 50°C / min, constant temperature 3 After hours, the temperature was lowered to room temperature at 5°C / min. After the resulting product was acid washed with HF to remove the template, a regular porous carbon was obtained.

[0018] Put the porous carbon into a tube furnace heated by resistance wire for high-temperature heat treatment. Under the protection of nitrogen, the temperature is increased from room temperature to 1600°C at a rate of 5°C / min, and then kept at this temperature for 5 hour...

Embodiment 2

[0021] Add 200mg of the template material β-zeolite molecular sieve into the quartz reactor, inject 99.999% nitrogen at a flow rate of 300ml / min, use a high-frequency heating device to heat up to 650°C at a heating rate of 50°C / min, and then at a flow rate of 50ml / min Pass in 99.99% high-purity acetylene gas, perform chemical vapor deposition at a constant temperature for 2 hours, stop passing acetylene gas, continue to pass in 99.999% nitrogen at a flow rate of 125ml / min, and heat up to 1000°C at a heating rate of 50°C / min. After being kept at a constant temperature for 3 hours, the temperature is reduced to room temperature at 5°C / min. After the resulting product is acid washed with HF to remove the template, a regular porous carbon is obtained.

[0022] Add this porous carbon to a tube furnace heated by resistance wire for high-temperature heat treatment. Under the protection of nitrogen, it is heated from room temperature to a final temperature of 1000°C at a rate of 5°C / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com