Comprehensive approach for recycling waste water

A comprehensive treatment and waste water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. and other problems to achieve the effect of reducing energy consumption, saving aeration volume, improving water permeability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

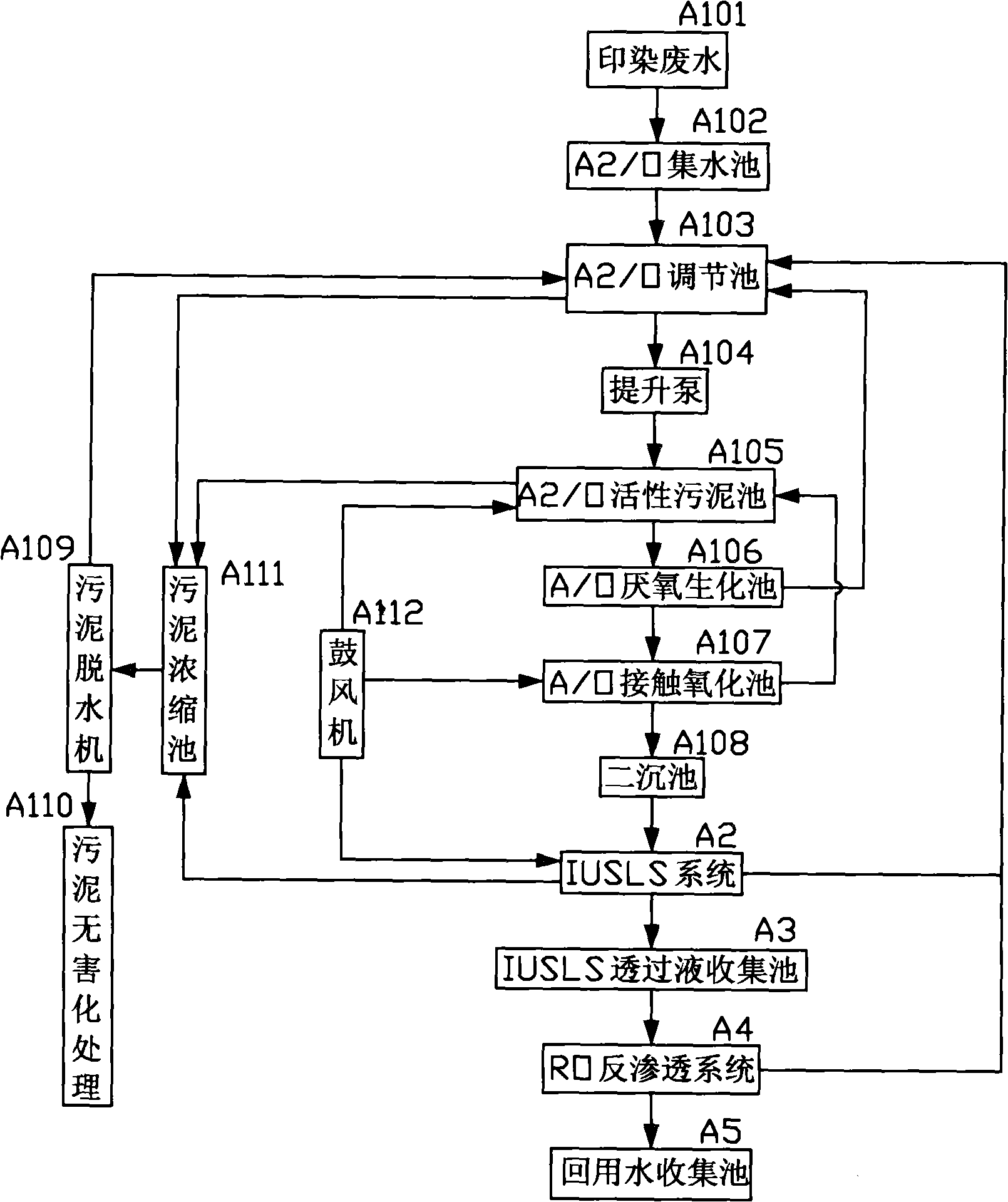

[0018] This embodiment is a comprehensive treatment method for printing and dyeing wastewater. refer to figure 1 , printing and dyeing wastewater A101 is processed through A2 / O sump A102, A2 / O regulating pool A103, lift pump A104, A2 / O activated sludge pool A105, A / O anaerobic biochemical pool A106, A / O contact oxidation pool A107 for A2 / O plus A / O process multi-stage biochemical combination treatment, that is, the multi-level biochemical combination treatment of printing and dyeing wastewater and sludge through anaerobic → anoxic → activated sludge aerobic → anaerobic → contact oxidation aerobic, not only makes The COD or BOD in the water is degraded, and biological denitrification can be effectively realized. Through the two biochemical processes of nitrification and denitrification, the nitrogen-containing compounds in the sewage are decomposed into HH by heterotrophic ammonification bacteria. 4+ , and then under aerobic conditions, through the action of nitrous bacteria ...

Embodiment 2

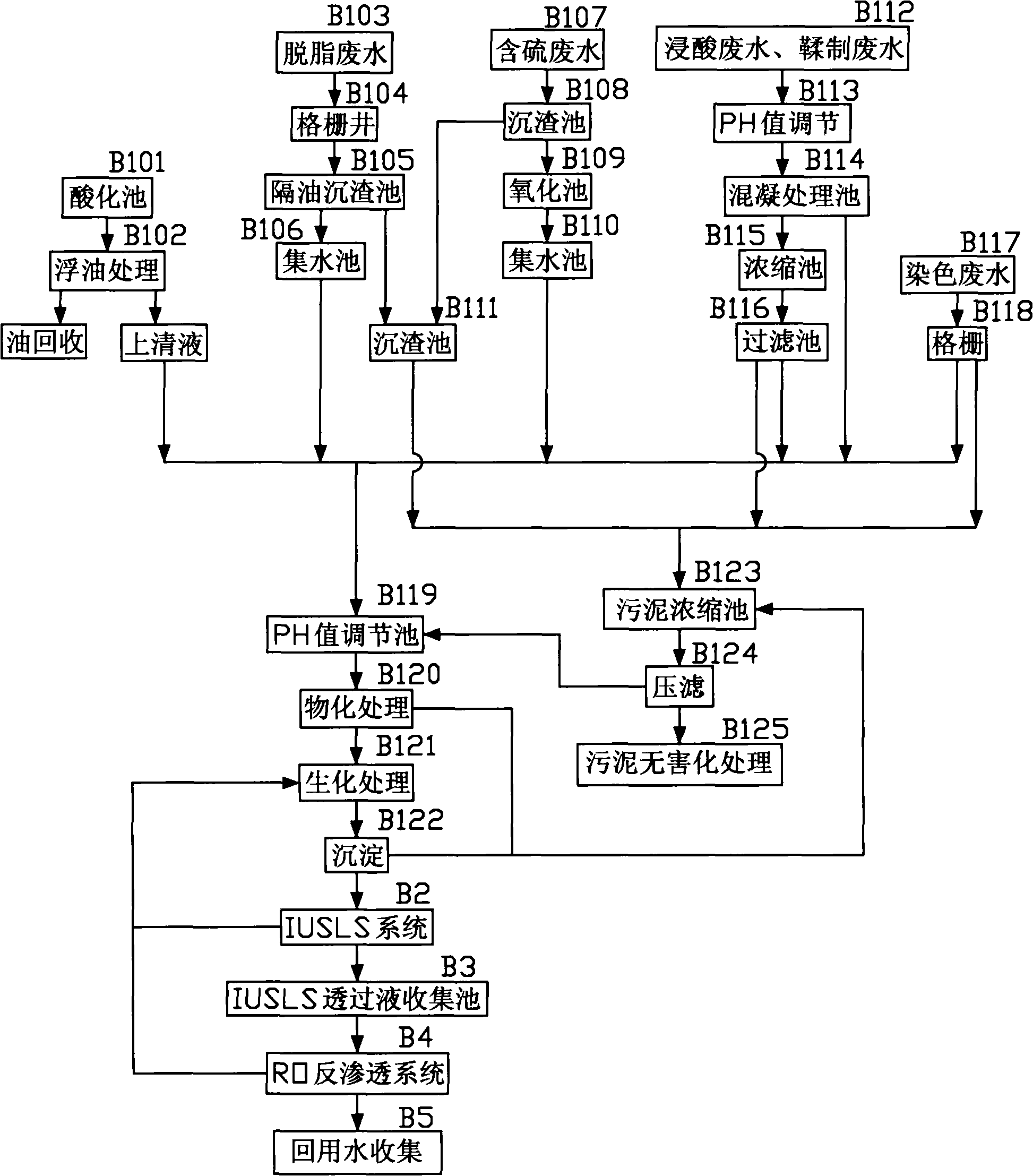

[0026] This embodiment is a comprehensive treatment method for leather wastewater, which contains a relatively high concentration of Cr 3+ , sulfide, grease and other substances that inhibit and poison microorganisms, as well as organic matter and solid floating objects. At the same time, the water quantity and quality vary greatly. The purpose of pretreatment is to reduce the load of organic matter and toxic substances in wastewater and ensure the stable and normal operation of the biological system. And make the effluent of the biochemical sedimentation tank reach the water quality standard for discharge.

[0027] refer to figure 1 , the effluent from the acidification pool B101 is treated with oil slick B102, the oil is recovered, and the supernatant enters the PH value adjustment pool B119; the degreasing wastewater B103 is filtered through the grid well B104, the oil separation sediment pool B105, and after sedimentation, it enters the sump B106. The water in the sump ta...

Embodiment 3

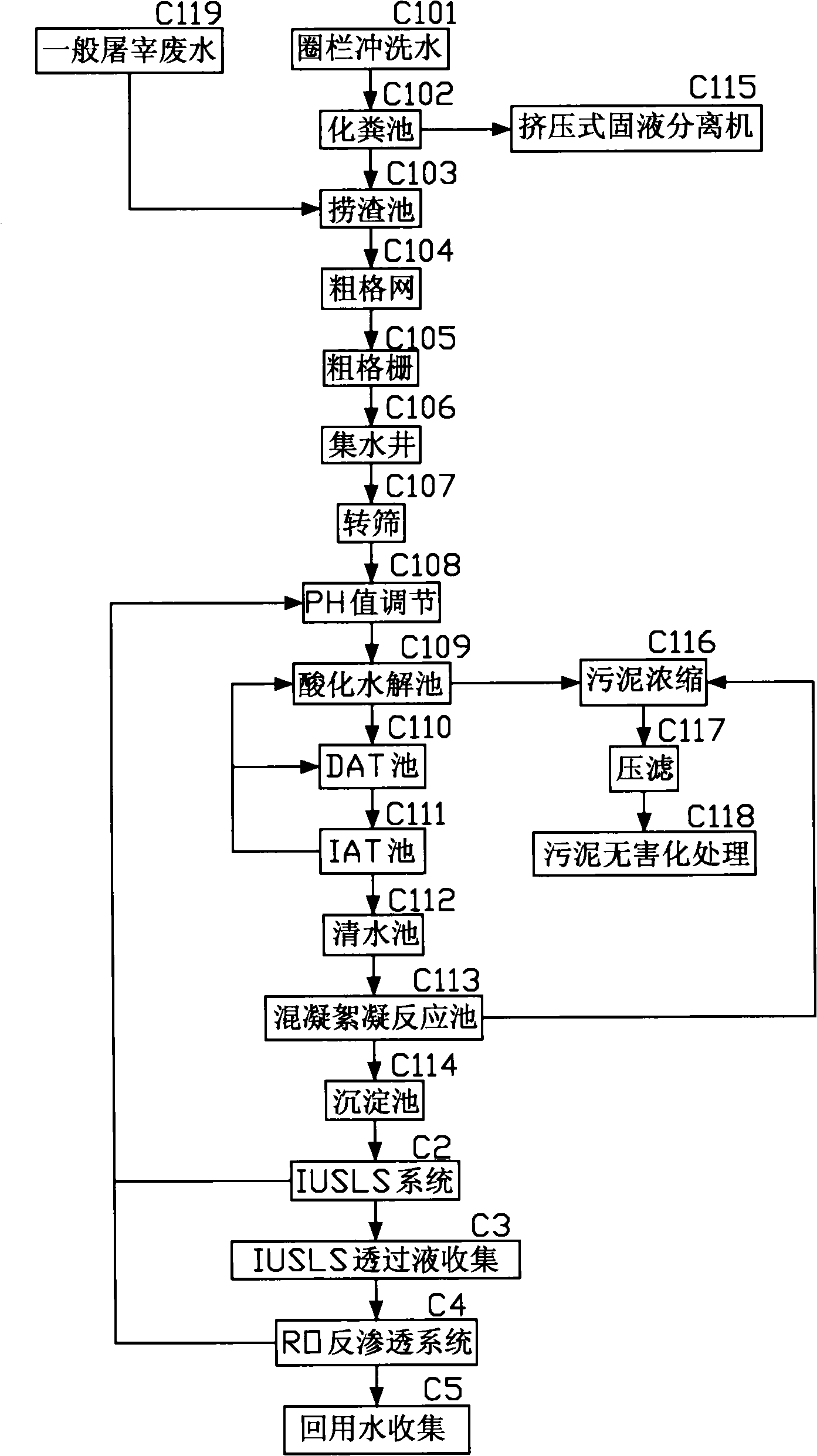

[0032] This embodiment is a comprehensive treatment method for slaughter wastewater. refer to image 3 , The pen flushing water C101 enters the septic tank C102 for treatment, and the sediment enters the extrusion solid-liquid separator C115 for treatment, and the obtained solids can be used as feed. The turbid liquid in the septic tank C102 is filtered through the slag removal tank C103, the coarse grid C104, the coarse grid C105, the water collection well C106, and the rotary screen C107, and then enters the pH adjustment tank C108. Generally, the slaughter wastewater C119 directly enters the slag removal tank C103 without septic treatment.

[0033] The effluent from the PH value adjustment tank C108 passes through the acidification hydrolysis tank C109, and then enters the DAT tank C110 and the IAT tank C111 in turn. The sludge produced in the acidification hydrolysis tank C109 is treated with sludge concentration C116, and then the sludge is processed after pressure filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com