Metal semiconductor field effect light emitting transistor and preparing method thereof

A technology of light-emitting transistors and metal semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve problems affecting device characteristics, etching products and mask material pollution, n-type GaN Schottky contact effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

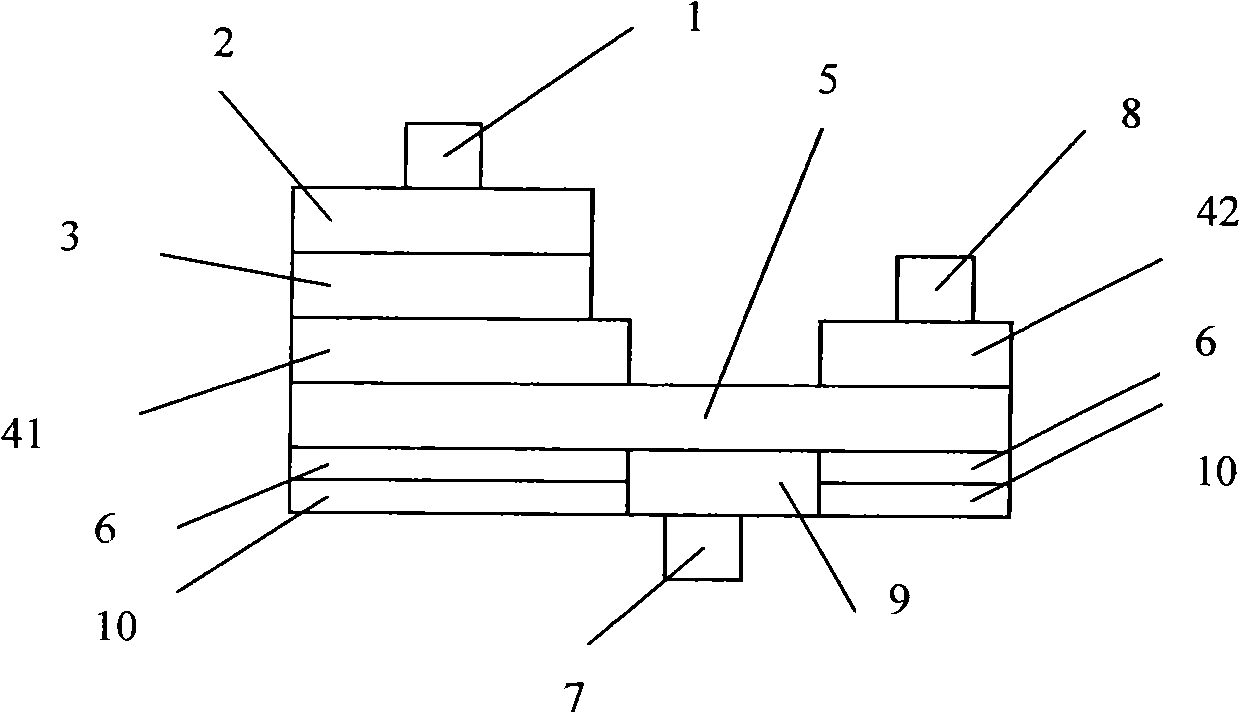

[0023] Metal-semiconductor field-effect light-emitting transistors are prepared according to the following steps, and the substrate is GaN:

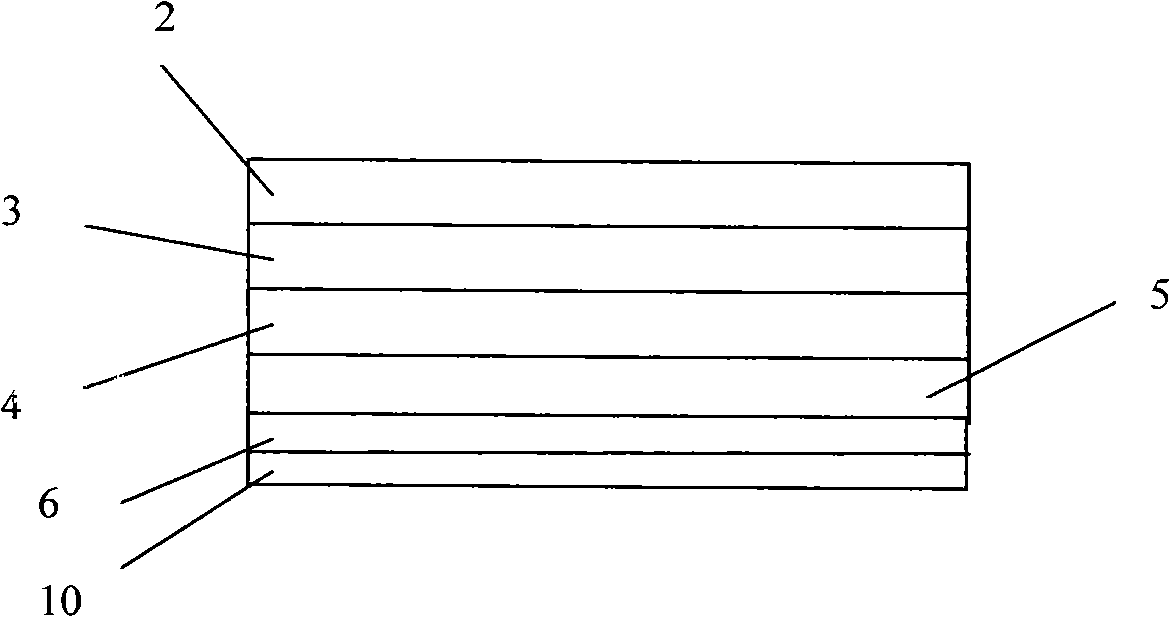

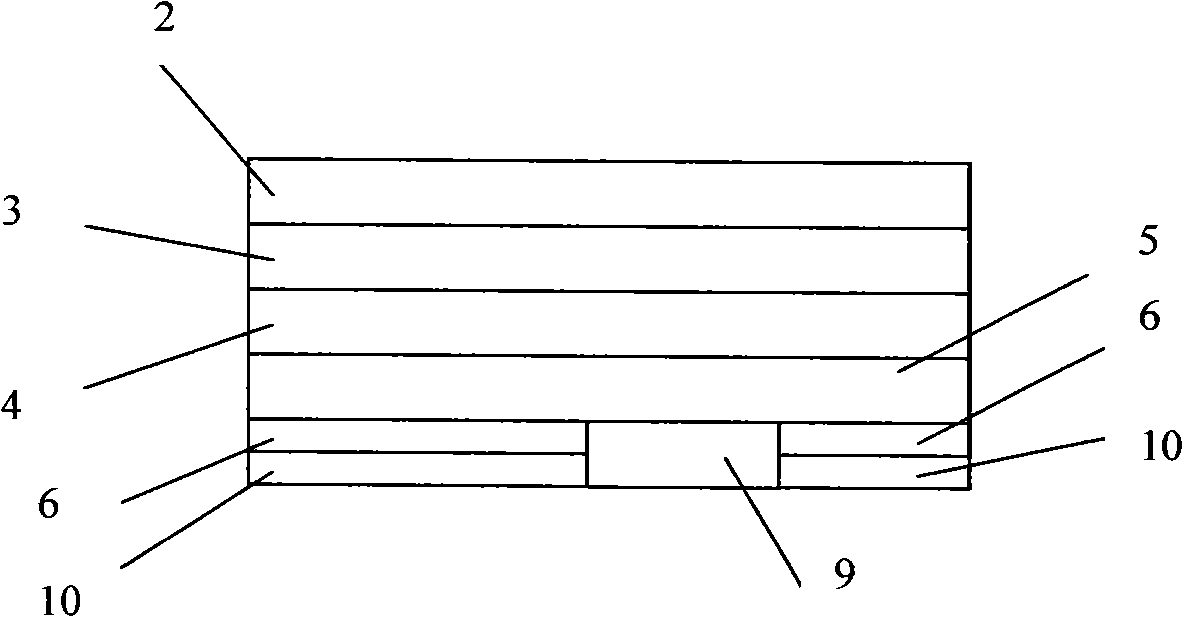

[0024] (1) if figure 2 As shown, a 2.0um thick GaN buffer layer 6 is grown on a square sapphire substrate 10;

[0025] (2) if figure 2 As shown, a 3.0um thick low-doped n-type layer 5 is grown on the buffer layer 6, GaN is doped with Si, and the doping concentration is 10 17 cm -3 ;

[0026] (3) if figure 2 As shown, continue to grow a 3um thick highly doped n-type layer 4 as the electron emission region, GaN doped with Si, and the doping concentration is 10 19 cm -3 ;The forbidden band width is 3.4eV;

[0027] (4) if figure 2 As shown, continue to grow the superlattice structure of GaN / InGaN material to form a multi-quantum well layer 3, which serves as the high-brightness active light-emitting region of the transistor, forming 10-20 quantum wells, and the thickness of the active region is 150-300nm;

[0028] (5) if figur...

Embodiment 2

[0035] Metal-semiconductor field-effect light-emitting transistors are prepared according to the following steps, and the substrate is GaN:

[0036] (1) if figure 2 As shown, a 2.0um thick GaN buffer layer 6 is grown on a square sapphire substrate 10;

[0037] (2) if figure 2 As shown, a 3.0um thick low-doped n-type layer 5 is grown on the buffer layer 6, GaN is doped with Si, and the doping concentration is 10 17 cm -3 ;

[0038] (3) if figure 2 As shown, continue to grow a 3um thick highly doped n-type layer 4 as the electron emission region, GaN doped with Si, and the doping concentration is 10 19 cm -3 ;The forbidden band width is 3.4eV;

[0039] (4) if figure 2 As shown, continue to grow the superlattice structure of GaN / InGaN material to form a multi-quantum well layer 3, which serves as the high-brightness active light-emitting region of the transistor, forming 10-20 quantum wells, and the thickness of the active region is 150-300nm;

[0040] (5) if figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com