Process for preparing bifunctional catalyst for preparing dimethyl ether directly with synthesis gas

A dual-function catalyst and synthesis gas technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of cumbersome preparation process, long time-consuming, high temperature, etc., achieve simple preparation process and overcome cumbersome process , the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 43.5 grams of copper nitrate, 26.8 grams of zinc nitrate and 11.2 grams of aluminum nitrate were dissolved in absolute ethanol to make a mixed solution, and 11 grams of HZSM-5 (Si / Al=60) molecular sieves as methanol dehydration components were added to the above mixed solution. solution, and then stirred thoroughly to obtain a suspension. Add an ethanol solution containing 45 grams of oxalic acid to the above suspension under stirring to obtain a precipitate. The obtained sediment is aged at room temperature for half an hour, then filtered, dried, and then calcined at 350° C. for 6 hours to obtain a catalyst powder. Finally, through tableting, crushing and sieving 20-40 mesh particles to obtain bifunctional catalyst A, wherein the weight percentage of each component is CuO 40%, ZnO 20%, Al 2 o 3 7%, H-ZSM-5 33%.

Embodiment 2

[0037] Dissolve 43.5 grams of copper nitrate, 26.8 grams of zinc nitrate and 11.2 grams of aluminum nitrate in absolute ethanol to make mixed solution a, dissolve 45 grams of oxalic acid in absolute ethanol to make solution b, and use 11 grams as methanol dehydration component The HZSM-5 (Si / Al=60) molecular sieve was added into absolute ethanol to prepare suspension c. Add solutions a and b simultaneously to the above suspension c under stirring to obtain a precipitate. The obtained sediment is aged at room temperature for half an hour, then filtered, dried, and then calcined at 350° C. for 6 hours to obtain a catalyst powder. Finally, bifunctional catalyst B was obtained by tableting, pulverizing and sieving 20-40 mesh particles, wherein the weight percentage of each component was the same as that of Example 1.

Embodiment 5

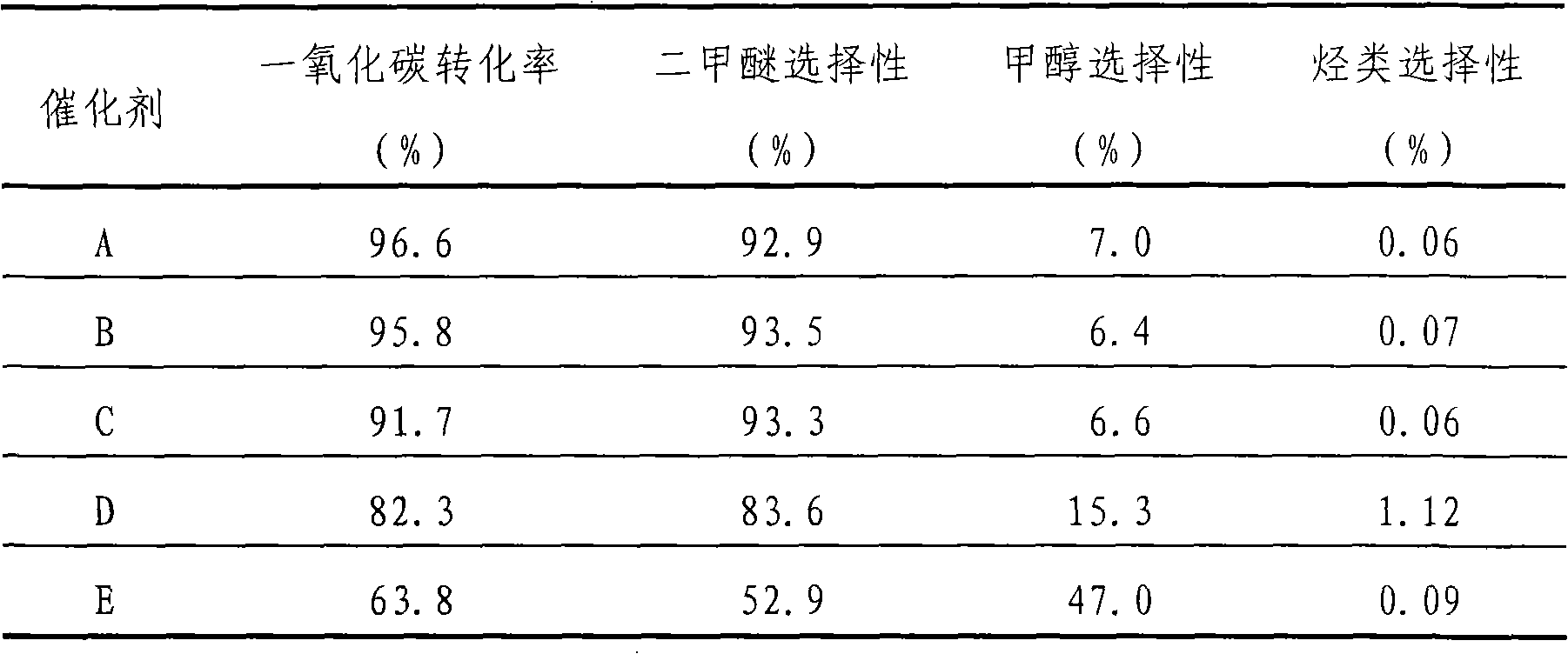

[0045] Catalysts A, B, C, D and E prepared in Examples 1, 2 and Comparative Examples 1-3 were used for gas phase reaction in a continuous flow fixed bed pressurized reaction evaluation device, and the loading amount of the catalyst was 1 g. After the catalyst is filled, the reducing gas (5% H 2 / 95%N 2 , the flow rate is 25ml / min), and the temperature is raised to 240°C. After 6 hours of reduction, the temperature of the catalyst bed is reduced to 200°C under the condition of continuing to pass the reducing gas, and then the raw material gas is switched and the temperature is gradually raised to the desired reaction temperature. temperature to react. The composition (volume fraction) of raw gas is CO: 31.1%, CO 2 : 5.7%, the rest is H 2 . The reaction conditions are pressure: 4MPa, space velocity: 1500ml / g cat h -1 . After 3 hours of reaction, the system reached equilibrium, and then samples were taken for analysis. Use HP 4890D gas chromatograph on-line, use thermal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com