Method for continuous preparation of epoxypropane

A technology of propylene and hydrogen peroxide, applied in the production of bulk chemicals, organic chemistry, etc., can solve the problems of serious environmental pollution, poor economy, catalyst deactivation, etc., and achieve the effects of reducing side reactions, small equipment investment, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

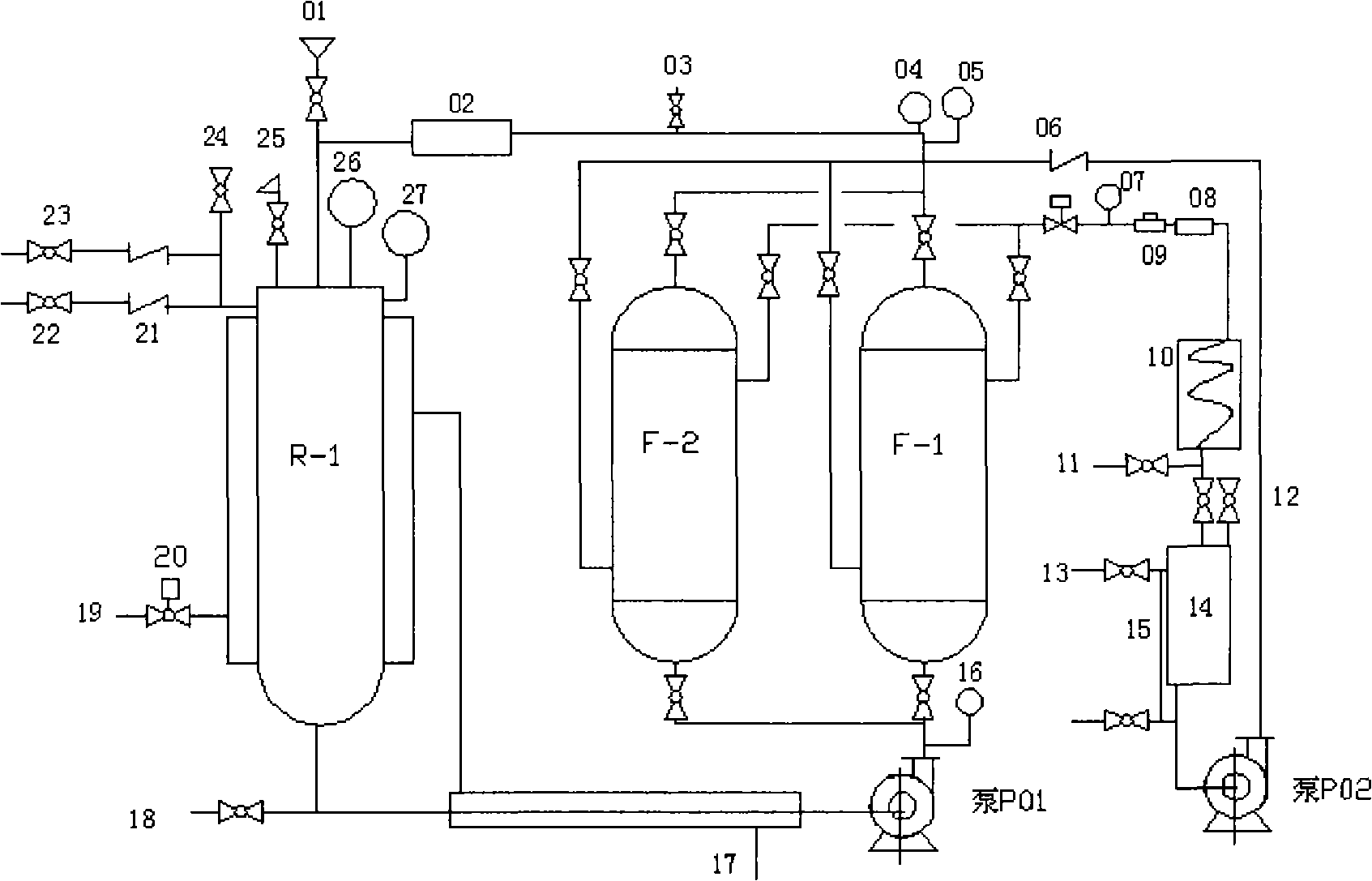

Method used

Image

Examples

Embodiment 1

[0029] Weigh 50g of HTS molecular sieve and place it in the methanol solution of hydrogen peroxide, stir to form a slurry, and then inject it into the reaction system through the catalyst feeding port. Open the feed valve of the liquid-phase raw material (methanol solution of hydrogen peroxide) and backpressure until the system pressure is 2.0 MPa, then open the feed valve of propylene and control the reaction temperature to 40°C. In the reaction system, the molar ratio of methanol to hydrogen peroxide in the liquid phase raw material is 40:1, the molar ratio of propylene to hydrogen peroxide is 2:1, and the space time is 1.5h.

[0030] The results of regular sampling analysis are: the conversion rate of hydrogen peroxide is greater than 98%, the selectivity of propylene oxide is 93%, the selectivity of 1-methoxyl-2-propanol is 2.3%, the selectivity of 2-methoxyl-1-propanol The selectivity to alcohol was 3.2%, and the selectivity to propylene glycol was 1.5%.

Embodiment 2

[0032] Weigh 40g of HTS titanium-silicon molecular sieve and place it in the methanol solution of hydrogen peroxide, stir to form a slurry, and then inject it into the reaction system through the catalyst feeding port. Open the feed valve of the liquid-phase raw material, when the back pressure reaches a system pressure of 2.0 MPa, open the propylene feed valve after the system pressure is stable, and control the reaction temperature at 35°C. The molar ratio of methanol and hydrogen peroxide in the liquid phase raw material is 40:1, the molar ratio of propylene and hydrogen peroxide is 2:1, and the reaction space time is 2.0h.

[0033] The results of regular sampling analysis are: the conversion rate of hydrogen peroxide is greater than 98%, the selectivity of propylene oxide is 95%, the selectivity of 1-methoxyl-2-propanol is 1.7%, the selectivity of 2-methoxyl-1-propanol The selectivity to alcohol was 2.3%, and the selectivity to propylene glycol was 1.0%.

Embodiment 3

[0035]Weigh 50g of HTS titanium-silicon molecular sieve and place it in the methanol solution of hydrogen peroxide, stir to form a slurry, and then inject it into the reaction system through the catalyst feeding port. Open the feed valve of the liquid-phase raw material, when the back pressure reaches a system pressure of 2.0 MPa, open the propylene feed valve after the system pressure is stable, and control the reaction temperature at 35°C. The molar ratio of methanol to hydrogen peroxide in the liquid phase raw material is 40:1, the molar ratio of propylene to hydrogen peroxide is 2:1, and the reaction space time is 3.0h.

[0036] The results of regular sampling analysis are: the conversion rate of hydrogen peroxide is greater than 98%, the selectivity of propylene oxide is 91%, the selectivity of 1-methoxyl-2-propanol is 2.0%, the selectivity of 2-methoxyl-1-propanol Alcohol selectivity was 5.5%, propylene glycol selectivity was 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com