Composite solid super acidic catalyst and preparation method thereof

A solid superacid and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as lower specific surface area, lower catalyst activity, and lower activity of solid superacids. Effect of high, increased content, low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of above-mentioned composite solid superacid catalyst comprises the following steps:

[0018] a. Under ice-water bath conditions, the titanium tetrachloride aqueous solution with a concentration of 1 to 5wt% and the zirconium oxychloride aqueous solution with a concentration of 1 to 5wt% are mixed, the weight ratio of the titanium tetrachloride aqueous solution to the zirconium oxychloride aqueous solution 1:0.5~2, add ethanol as a dispersant, then add ammonia water and stir to make the pH value of the mixed solution in the range of 9~10, generate zirconium hydroxide and titanium hydroxide precipitation, add 0.1~0.5mol / L nitric acid solution to generate the sol of zirconium hydroxide and titanium hydroxide;

[0019] b. Filter and wash the sol until the pH of the filtrate is 6.9-7.1 without Cl - ions, followed by drying to obtain ZrO 2 and TiO 2 mixed precursor oxides;

[0020] c. Mix the above-mentioned mixed precursor oxide with aluminum hali...

Embodiment 1

[0028] Under the condition of ice-water bath, the concentration of 1wt% TiCl 4 The aqueous solution and the zirconium oxychloride aqueous solution with a concentration of 1 wt% are mixed according to the ratio of 1:0.5, and ethanol is added as a dispersant, and the volume ratio of the mixed liquid to ethanol is 1:5. Use ammonia water to adjust the pH value of the solution to the range of 9-10, and stir when adding the ammonia water to form zirconium hydroxide and titanium hydroxide precipitates. Then add 0.1mol / L nitric acid solution to the precipitate to generate zirconium hydroxide and titanium hydroxide sol, and the relative ratio of the precipitate to the nitric acid solution is 1:0.1. The sol was filtered and washed until the filtrate pH was 7 and Cl-free - , and then dried to obtain a mixed precursor oxide. The mixture of mixed precursor oxide and aluminum fluoride powder was ground to 3 ) 2 Soluble in 0.5mol / L H 2 SO 4 A sulfuric acid solution of 0.1mol / L nickel ni...

Embodiment 2

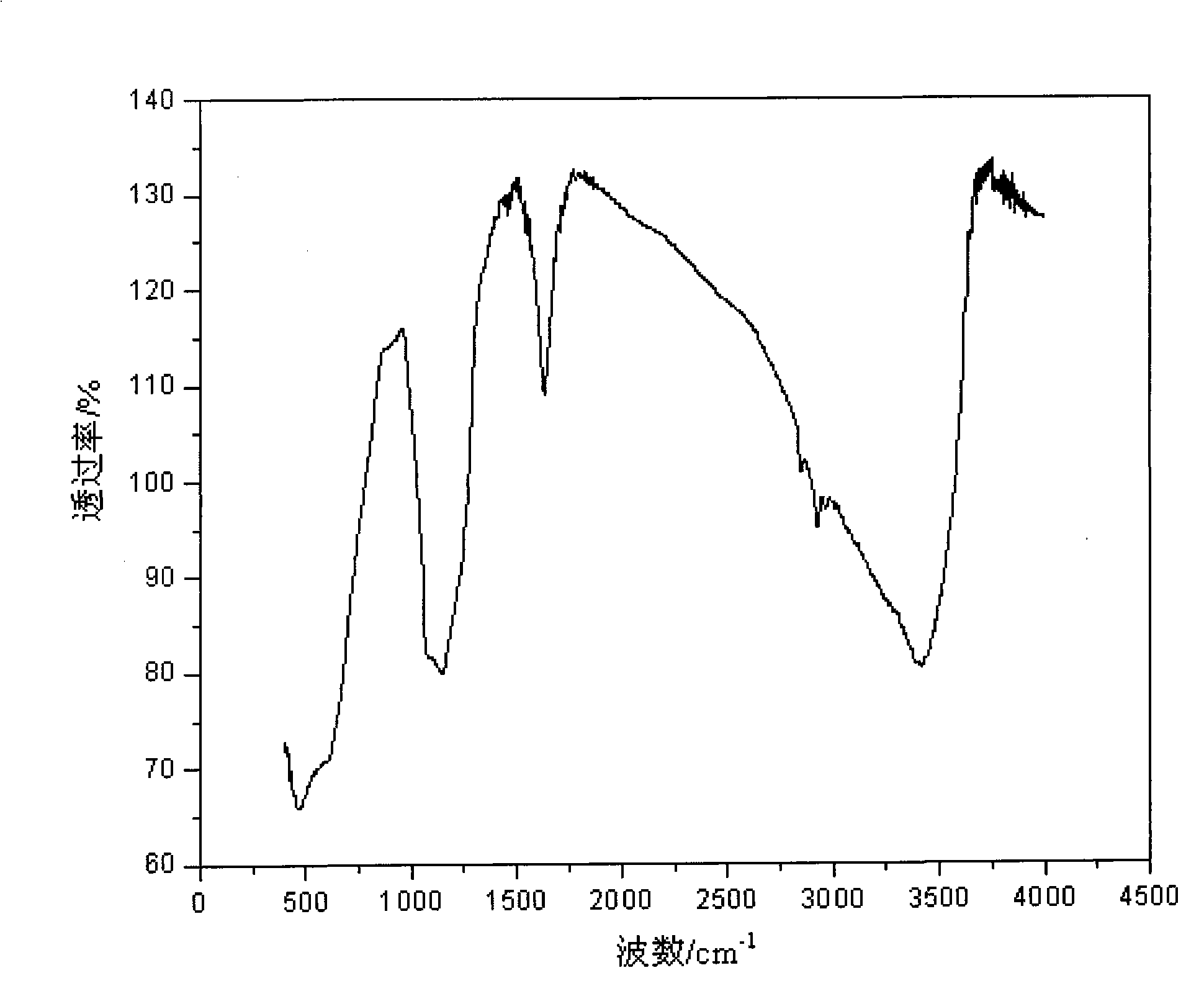

[0032] Catalyst is prepared by the method of embodiment 1, difference is that concentration is 1wt% TiCl 4 The aqueous solution and the zirconium oxychloride aqueous solution with a concentration of 1wt% are mixed according to the ratio of 1:2, and the AlF in the mixture of the precursor oxide and the aluminum fluoride powder is mixed. 3 The content is 3wt%, and the calcination temperature of the catalyst is 700°C. The impregnating solution is a certain amount of Ni(NO 3 ) 2 Soluble in 0.5mol / L H 2 SO 4 A sulfuric acid solution of 0.5mol / L nickel nitrate was made in the medium. The ground mixture is put into a sulfuric acid solution containing transition metal ions for immersion, and the immersion time is 10 hours. Mixture with Ni 2+ The weight ratio of sulfuric acid solution is 1:20, figure 1 It is the IR spectrogram of the composite type solid superacid catalyst containing rare earth of the present invention, and the character of gained catalyst and product yield are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com