Composite plumbago-carbon negative pole material and method of manufacturing the same

A technology of composite graphite and negative electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor fast charge and discharge performance, long lithium ion diffusion path, low raw material utilization rate, etc., and achieve good high current charge and discharge performance , The preparation method is environmentally friendly and the treatment cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 90 kilograms (kg) of petroleum coke micropowder (Fushun Longpeng Chemical Co., Ltd., D 50 1 μm) and 30 kilograms of coal tar pitch (Anshan Iron and Steel Co., Ltd.), were added to the reactor alternately while stirring, and continued to stir for 1 hour after feeding, and then under nitrogen protection (nitrogen flow rate 0.1m 3 / h), the temperature was raised to 500°C at a rate of 1°C / min, and kept at a constant temperature of 500°C for 300 minutes, and then the reaction product was cooled to room temperature before conventional graphitization (2800°C), and the prepared composite artificial graphite The average particle size of the carbon negative electrode material is 6 μm, and the specific surface area measured by the BET (Brunauer-Enmet-Teller) method, that is, the low-temperature nitrogen adsorption method, is 2.5 m 2 / g, the half-cell capacity is 338mAh / g, and the first-time efficiency is 93.0%.

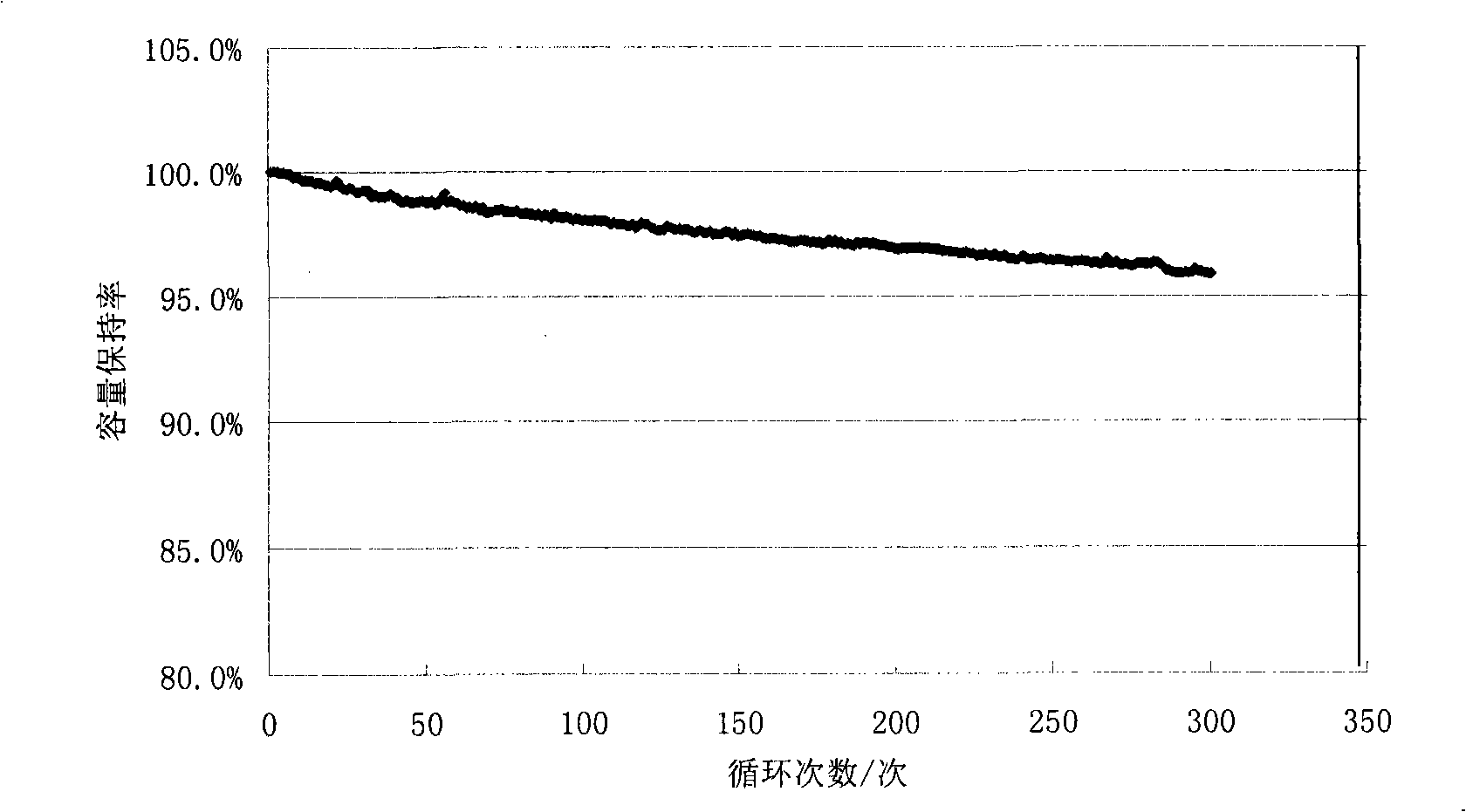

[0042] Use the composite graphite as the negative electrode, ...

Embodiment 2

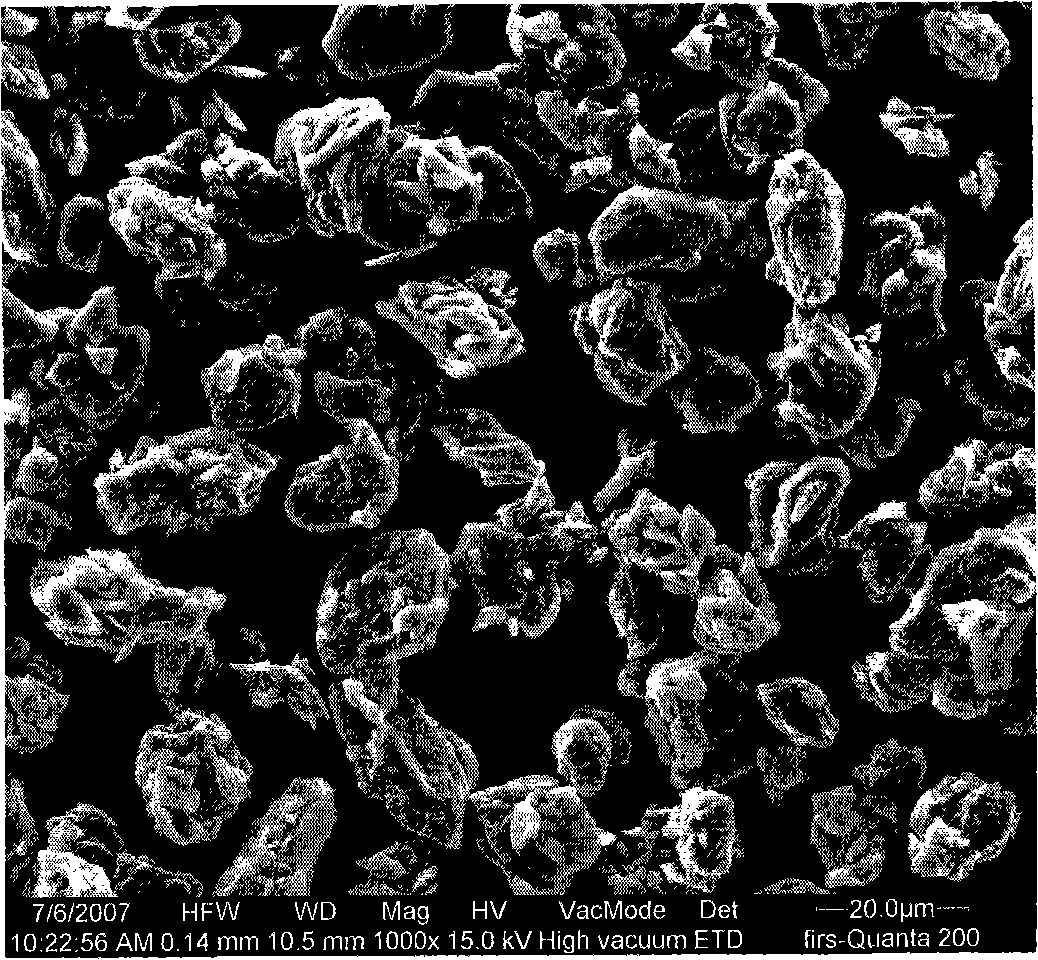

[0044] Take by weighing 120kg petroleum coke micropowder (Huludao City, Liaoning Huayu Carbon Factory, D 50 15 μm) and 10kg of petroleum pitch (Qingzhou Zhenhua Chemical Co., Ltd., Shandong Province), were added to the reactor alternately while stirring, and continued to stir for 0.1 hour after feeding, and then under nitrogen protection (nitrogen flow 0.5m 3 / h), heat up to 550°C at a rate of 0.6°C / min, and keep the temperature at 550°C for 60 minutes, then cool the reaction product to room temperature and then perform conventional graphitization (3000°C) to obtain the composite of the present invention The average particle size of the artificial graphite carbon negative electrode material is 18 μm, and its electron microscope photo is as follows figure 2 As shown, it can be seen that the composite graphite material particles are uniform without agglomeration, and the specific surface area measured by the BET method is 1.8m 2 / g, the half-cell capacity is 347mAh / g, and the ...

Embodiment 3

[0047] Weigh 80kg artificial graphite powder (D 50 10 μm, Qingdao Aoke Graphite Products Factory) and 20kg coal tar (Anshan Iron and Steel Co., Ltd.), while stirring, add in the reaction kettle alternately, continue to stir for 2 hours after feeding, and then under nitrogen protection (nitrogen flow 2m 3 / h), heat up to 500°C at a rate of 1.5°C / min, and keep the temperature at 500°C for 210 minutes, then cool the reaction product to room temperature and then perform conventional graphitization (2600°C) to obtain the composite of the present invention The average particle size of the artificial graphite carbon negative electrode material is 18μm, and the specific surface area measured by the BET method is 1.3m 2 / g, the half-cell capacity is 345mAh / g, and the first-time efficiency is 93.5%.

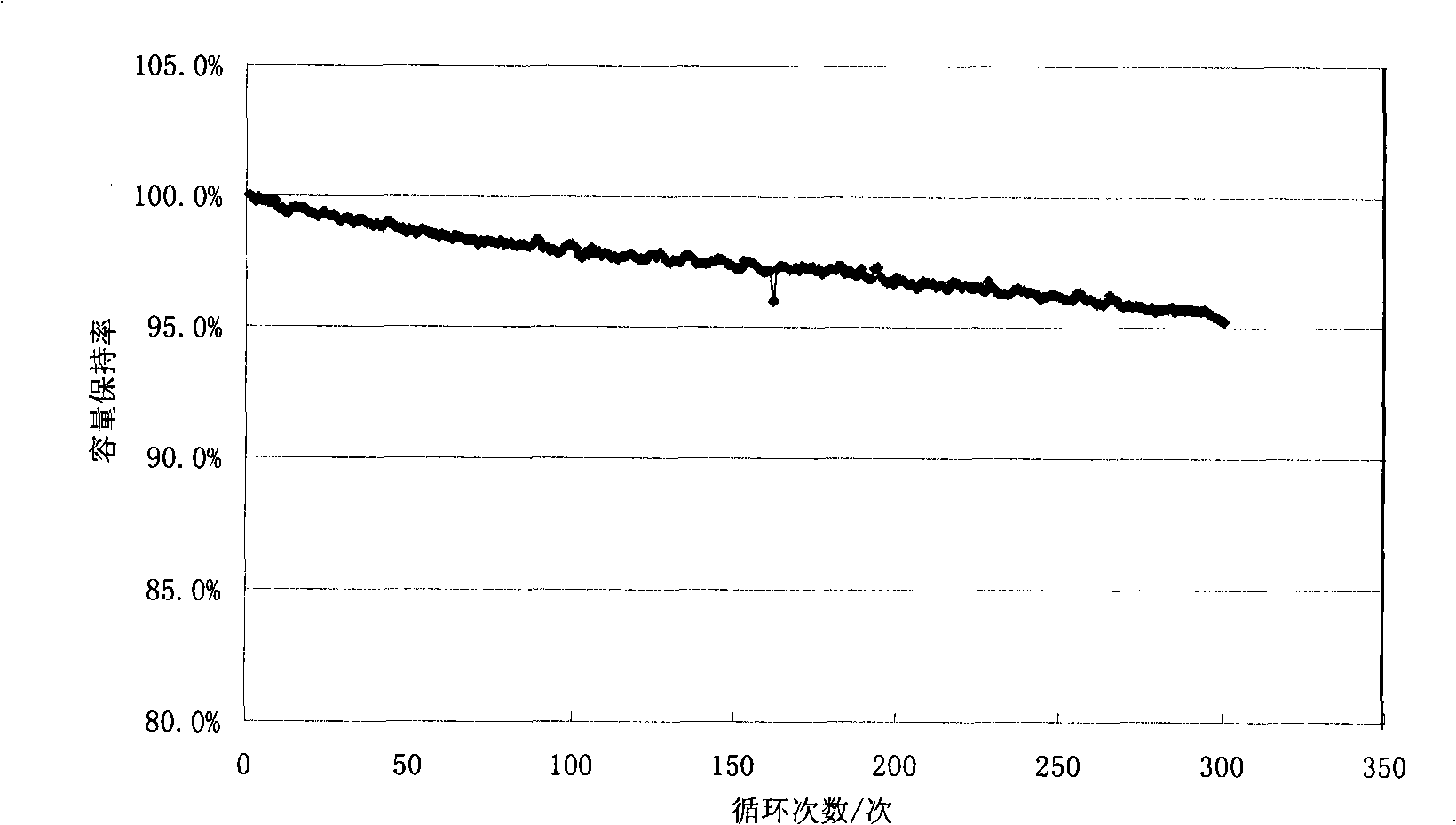

[0048] Use this composite graphite as negative electrode, lithium cobalt oxide as positive electrode, 1M-LiPF6EC: DMC: EMC = 1: 1: 1 solution as electrolyte to assemble a full battery, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com