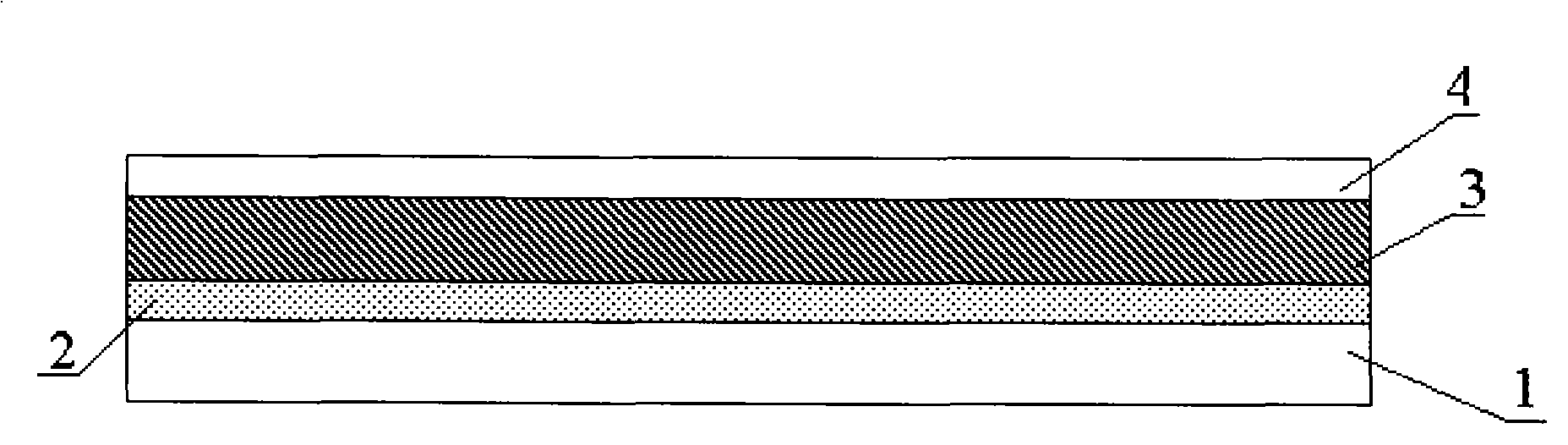

Reflection holography thin film and preparation method thereof

A holographic and film material technology, applied in the field of reflection holographic film and its preparation, can solve the problems of easy image erasing, short storage life, low reflection efficiency, etc., and achieve high refractive index modulation value, long storage life and high reflection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

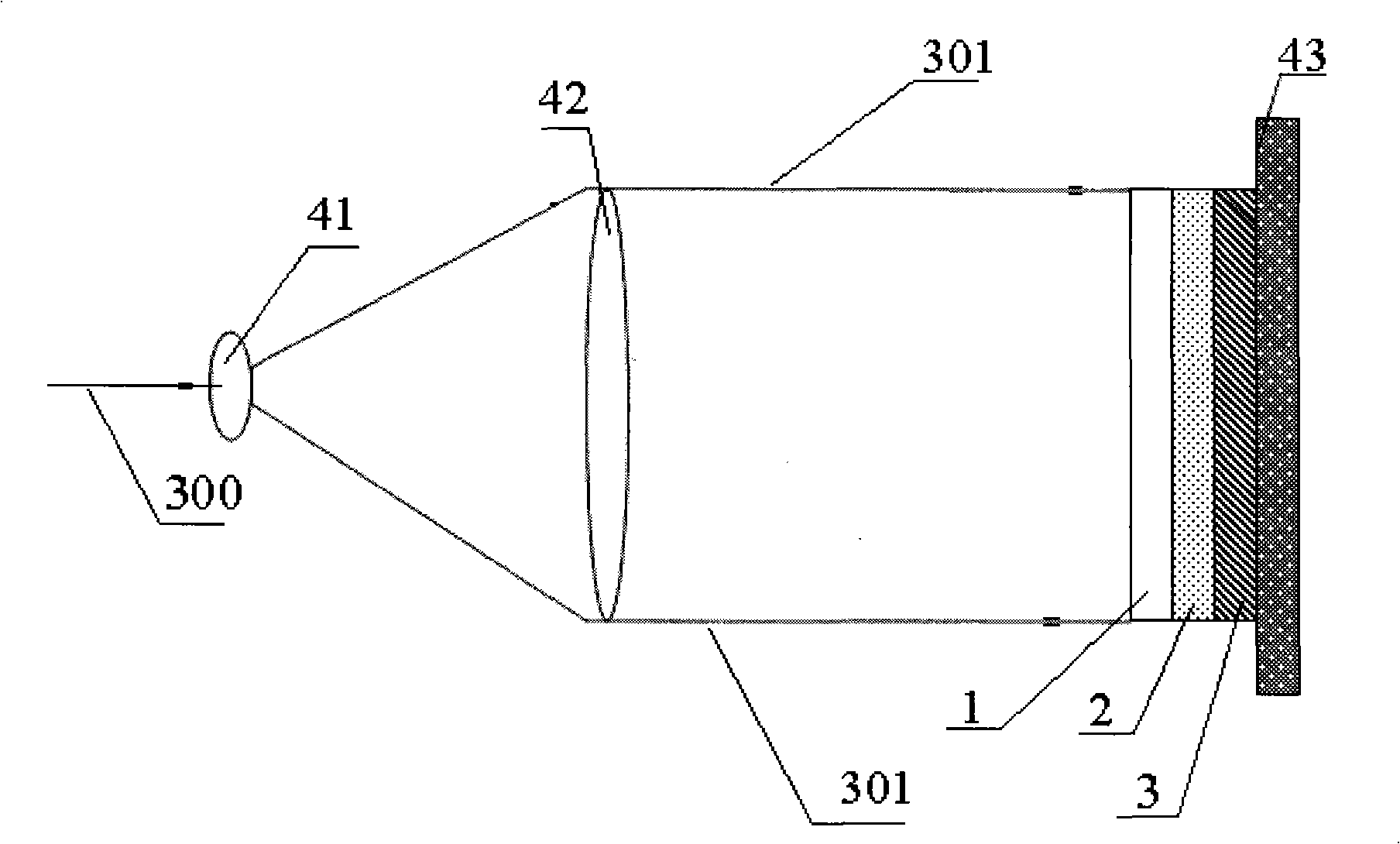

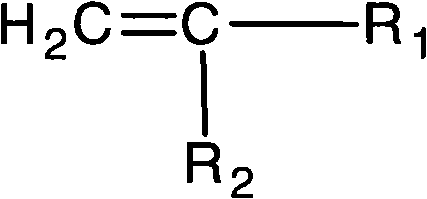

Method used

Image

Examples

Embodiment 1

[0067] Put 0.012g of azobisisobutyronitrile, 30g of methyl methacrylate and 0.2g of ZnS (with a particle size of 20nm) into a 100mL three-necked flask equipped with an electric stirrer, a condenser tube and a nitrogen pipe, and open the Cooling water, logical nitrogen, start stirrer, stirring speed is 800 rev / min). Heat to 75°C, take a sample after 20 minutes to make a methyl methacrylate prepolymer containing ZnS nanoparticles, then stop heating and cool to room temperature. Flush with nitrogen and store in refrigerator for later use. The weight content of the nanoparticles is 0.66%, and the measured weight average molecular weight is 5600.

Embodiment 2

[0069] Put 0.02g of dibenzoyl, 36g of 4-mercaptomethylstyrene and 0.35g of ZnS (with a particle size of 30nm) into a 100mL three-neck flask equipped with an electric stirrer, a condenser tube and a nitrogen pipe, and turn on the cooling water, nitrogen, and start the stirrer to mix evenly (stirring speed is 1200 rpm). Heat to 75°C and take a sample after 20 minutes. To make 4-mercaptomethylstyrene prepolymer containing ZnS nanoparticles, stop heating and cool to room temperature. Flush with nitrogen and store in refrigerator for later use. The weight content of the nanoparticles is 0.96%, and the weight-average molecular weight is 12000 according to the test.

Embodiment 3

[0071] Under the red safety light of wavelength greater than 600nm, with 9.2 grams (77wt%) film-forming agent polyvinyl acetate-butyl acrylate-acrylic acid terpolymer, monomer N-vinyl carbazole 1.0 grams (8.3wt%) , monomer tricyclodecane dimethanol diacrylate 0.6 gram (5wt%), the methyl methacrylate prepolymer 0.53 gram (4.4% embodiment 1) that contains ZnS nanoparticle, photoinitiator 2,4,6 - 0.078 grams (0.65wt%) of triphenylimidazole base doublet, 0.067 grams (0.056wt%) of photosensitizer diethylamino-benzylidene cyclopentanone, 0.04 grams (0.33wt%) of chain transfer agent 2-mercaptobenzothiazole wt%), UV absorber 2-hydroxyl-4-methoxybenzophenone 0.02 gram (0.17wt%), nonionic surfactant FC-44300.11 grams (0.92wt%), plasticizer diethyl sebacate 0.34 grams (2.8wt%) was added to the mixed solution (butanone: dichloromethane: methanol = 5:1:1, weight ratio) , with a weight solid content of 8%, stirred at room temperature until dissolved, the measured viscosity is 11cp (25°C),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com