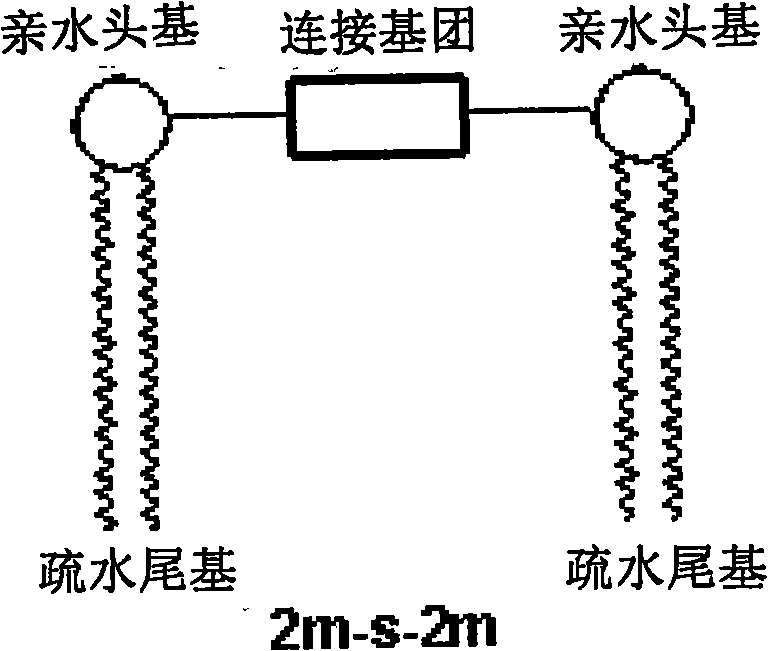

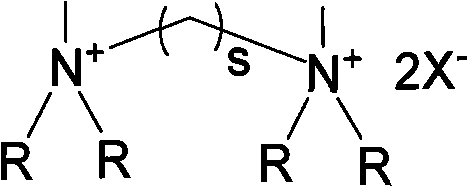

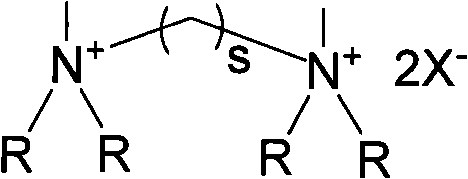

Double-tail gemini quaternary ammonium salt type cationic surface active agent and preparation method thereof

A technology of gemini quaternary ammonium salt and surfactant is applied in the field of long-chain aliphatic amine derivatives and their preparation, which can solve the problem of not finding research reports on double-tailed gemini cationic surfactants, and achieve good lipophilic performance and reaction Mild conditions and highly ordered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Accurately weigh 15.414g (0.042mol) of behenylmethyl tertiary amine in a two-necked flask equipped with a reflux condenser, add 4.04g (0.02mol) of dibromo-n-propane at room temperature, add 20ml of acetonitrile, and After injecting nitrogen gas for 20 minutes, the reaction was performed under magnetic stirring at 83° C. for 10 to 15 hours. After the reaction, the solvent was distilled off under reduced pressure to obtain a yellowish colloidal substance, which was precipitated at low temperature by adding acetone, filtered, washed twice with acetone, and dried in vacuo to obtain a white powdery solid 212-3-212.

Embodiment 2

[0031] Accurately weigh 15.414g (0.042mol) of behenylmethyl tertiary amine in a two-necked flask equipped with a reflux condenser, add 4.32g (0.02mol) of dibromobutane at room temperature, add 20ml of acetonitrile, After passing nitrogen gas for 20 minutes, the reaction was performed under magnetic stirring at 83° C. for 10 to 15 hours. After the reaction, the solvent was distilled off under reduced pressure to obtain a yellowish colloidal substance, which was precipitated at low temperature by adding acetone, filtered and washed twice with acetone, and dried in vacuum to obtain a white powdery solid 212-4-212.

Embodiment 3

[0033] Accurately weigh 15.414g (0.042mol) of behenylmethyl tertiary amine in a two-necked flask equipped with a reflux condenser, add 4.88g (0.02mol) of dibromo-n-hexane at room temperature, add 20ml of acetonitrile, and After injecting nitrogen gas for 20 minutes, the reaction was performed under magnetic stirring at 83° C. for 10 to 15 hours. After the reaction, the solvent was distilled off under reduced pressure to obtain a yellowish colloidal substance, which was precipitated at low temperature by adding acetone, filtered and washed twice with acetone, and dried in vacuum to obtain a white powdery solid 212-6-212.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com