Fiber reinforced inorganic doping cross-linking fluorinion-containing exchange film

An ion-exchange membrane and fiber-reinforced technology, which is applied in the field of functional polymer composite materials, can solve the problems of not improving the membrane dimensional stability and conductance at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

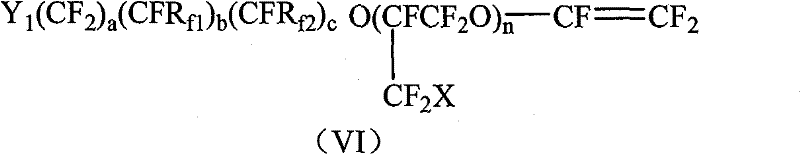

[0090] Example 1: The repeating unit is

[0091]

[0092] Polymer with EW=1000 and Zr(HPO 4 ) 2 (Zr(HPO 4 ) 2 The mass ratio with the resin is 3: 100) to make 5wt% propanol aqueous solution, then configure the perfluoromalonyl peroxide DMF solution with a concentration of 5%, add polytetrafluoroethylene fibers (diameter 1 μm, length 50 μm, The mass ratio of polymer to polymer is 7:100), dispersed and cast into a horizontally placed polytetrafluoroethylene mold. After vacuum drying at 80°C for 12 hours, the film was peeled off. 2 SO 4 The solution was boiled for 1 hour and washed with deionized water. After heat treatment, the membrane is sequentially treated with NaOH solution and sulfuric acid solution to obtain a fiber-reinforced single-layer perfluorosulfonic acid cross-linked as the (I) doped ion membrane.

Embodiment 2

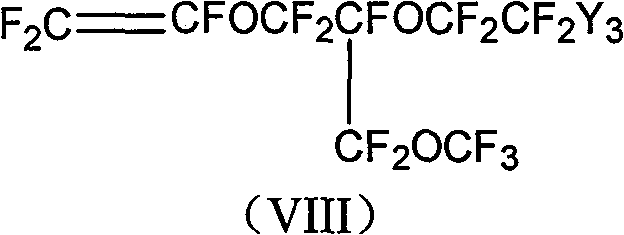

[0093] Example 2: The repeating unit is

[0094]

[0095] Polymer with EW=800 and particle size 0.03 μm SiO 2 (SiO 2 The mass ratio of perfluorosulfonic acid resin is 5:100), alkali-free glass fiber (diameter 0.05μm, length 5um, mass ratio of alkali-free glass fiber and perfluorosulfonic acid resin is 1:40), and extruded to obtain thickness for a 30 μm film. Soak in NH 4 Cl in DMF for 5 hours. The soaked membrane was then placed in triethylamine at 200°C for 2 hours to obtain a crosslinked membrane. The membrane is sequentially treated with KOH solution and hydrochloric acid solution to obtain an ion-exchange membrane with a cross-linked structure (II).

Embodiment 3

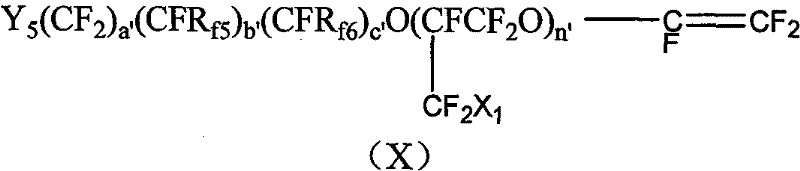

[0096] Embodiment 3: the repeating unit is

[0097]

[0098] Polymer with EW=1200, polytetrafluoroethylene fiber modified by silicic acid (diameter 0.2 μm, length 80 μm, weight ratio to polymer is 7:100), tetraphenyl tin extruded by twin-screw extruder 50 μm film, and then heat the film to 230° C. for 10 hours to obtain a film with the crosslinked structure (V). The membrane was sequentially treated with LiOH and nitric acid solution to obtain a cross-linked ion membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com