Compound osmotic pump controlled release preparation and preparation method thereof

A technology of controlled-release preparations and osmotic pumps, which is applied in the directions of pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc. than the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

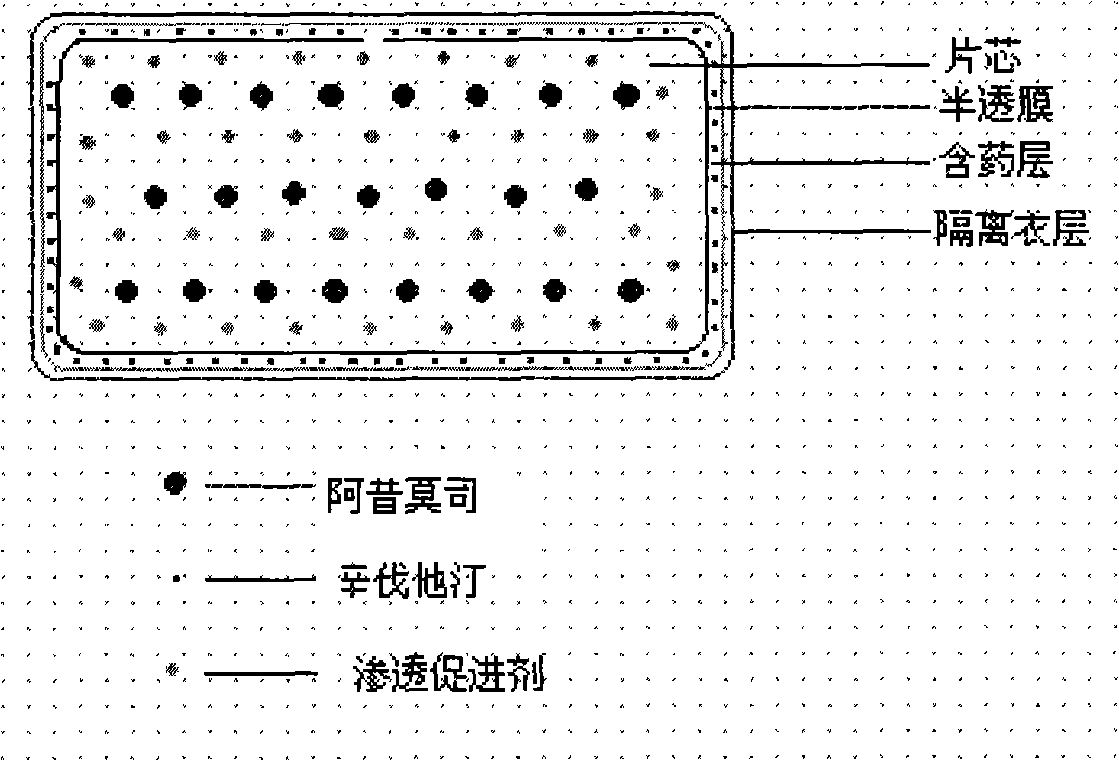

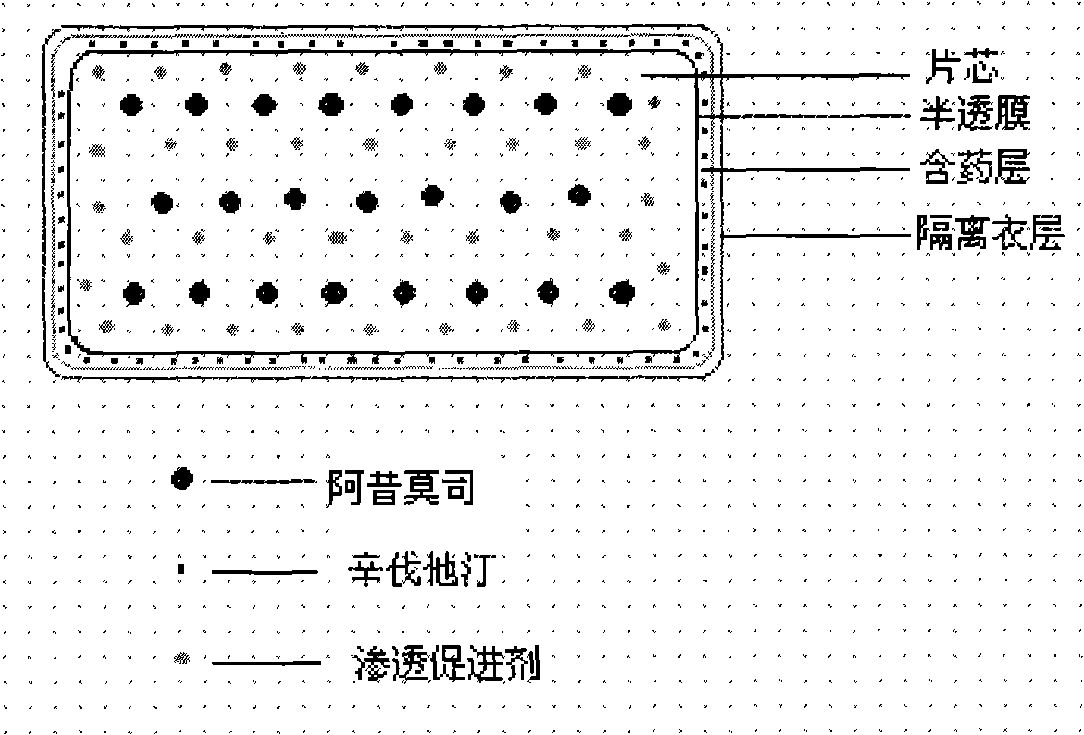

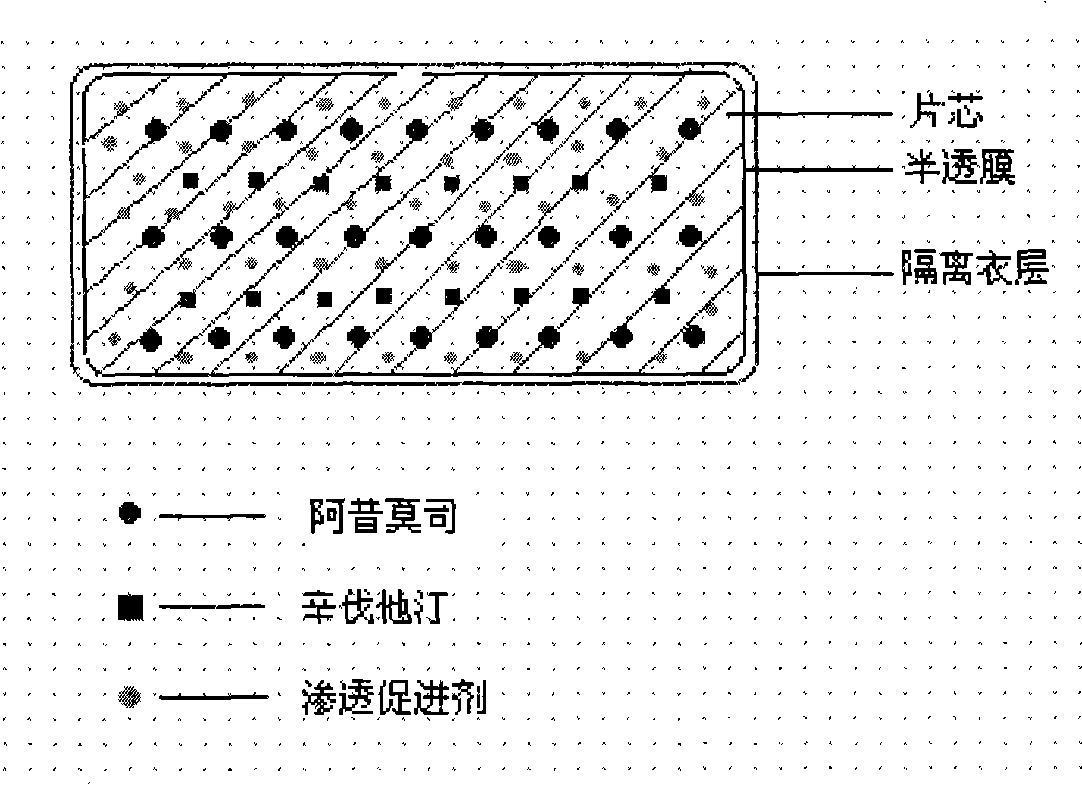

Image

Examples

Embodiment 1

[0109] Chip composition:

[0110] Acipimus 100g

[0111] NaCl 50g

[0112] PVPk30 2.5g

[0114] Coating film composition:

[0115] Cellulose acetate 6g

[0116] Macrogol 4000 1.5g

[0117] Diethyl phthalate 1g

[0118] Immediate release drug layer composition:

[0119] Simvastatin 10g

[0120] HPMC 6cp 6g

[0122] Isolation film coat layer:

[0123] Opadry II

[0124] Make 1000 tablets by the following preparation method: (1) Tablet core preparation Get sodium chloride and pulverize, cross 100 mesh sieves, mix with acipimox evenly, take 70% ethanol solution containing 8% PVPk30 as wetting agent, prepare Soft material, passed through a 20-mesh sieve to granulate, dried at 45°C for 2 hours, granulated, added with magnesium stearate, mixed evenly, compressed into tablets, and compressed into 1000 tablets by conventional tableting technology. (2) Tablet core coating: take cellulose acetate, add 280ml of acetone, s...

Embodiment 2

[0127] Chip composition:

[0128] Acipimus 150g

[0129] Fructose 45g

[0130] Lactose 45g

[0131] PVPk30 5g

[0133] Coating film composition:

[0134] Cellulose acetate 8g

[0135] Macrogol 4000 2g

[0136] Dibutyl sebacate 2g

[0137] Immediate release drug layer composition:

[0138] Simvastatin 10g

[0139] HPMC 6cp 6g

[0140] Sodium Lauryl Sulfate 2g

[0141] Titanium dioxide 1g

[0143] Make 1000 tablets by the following preparation method: (1) Tablet core preparation Get sodium chloride and pulverize, cross 100 mesh sieves, mix with acipimox evenly, take 70% ethanol solution containing 8% PVPk30 as wetting agent, prepare Soft material, passed through a 20-mesh sieve to granulate, dried at 45°C for 2 hours, granulated, added with magnesium stearate, mixed evenly, compressed into tablets, and compressed into 1000 tablets by conventional tableting technology. (2) Tablet core coating: take cellulose a...

Embodiment 3

[0146] Chip composition:

[0147] Acipimus 200g

[0148] NaCl 90g

[0149] pvp k30 5g

[0151] Coating film composition:

[0152] Ethylcellulose 12g

[0153] HPMC6cp 2g

[0154] Macrogol 4000 1g

[0155] Immediate release drug layer composition:

[0156] Simvastatin 10g

[0157] HPMC 6cp 6g

[0159] Isolation film coat layer:

[0160] Opadry II

[0161]Make 1000 tablets by the following preparation method: (1) tablet core preparation Get sodium chloride and pulverize, cross 100 mesh sieves, mix with acipimox evenly, take the 50% ethanol solution containing 5% HPMC6cp as wetting agent, prepare Soft material, passed through a 20-mesh sieve to granulate, dried at 5°C for 2 hours, granulated, added with magnesium stearate, mixed evenly, compressed into tablets, and compressed into 1000 tablets by conventional tableting technology. (2) Core coating: take ethyl cellulose, add 320ml of ethanol, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com