Method for preparing biodiesel, dodecoic acid, capric acid and monoglyceride thereof from Lindera communis fruits

A technology of biodiesel and lauric acid, applied in chemical instruments and methods, biofuels, biological raw materials, etc., can solve the problems of large equipment investment, complex production process, high production cost, etc., achieve high raw material utilization rate, reduce production cost, The effect of small side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

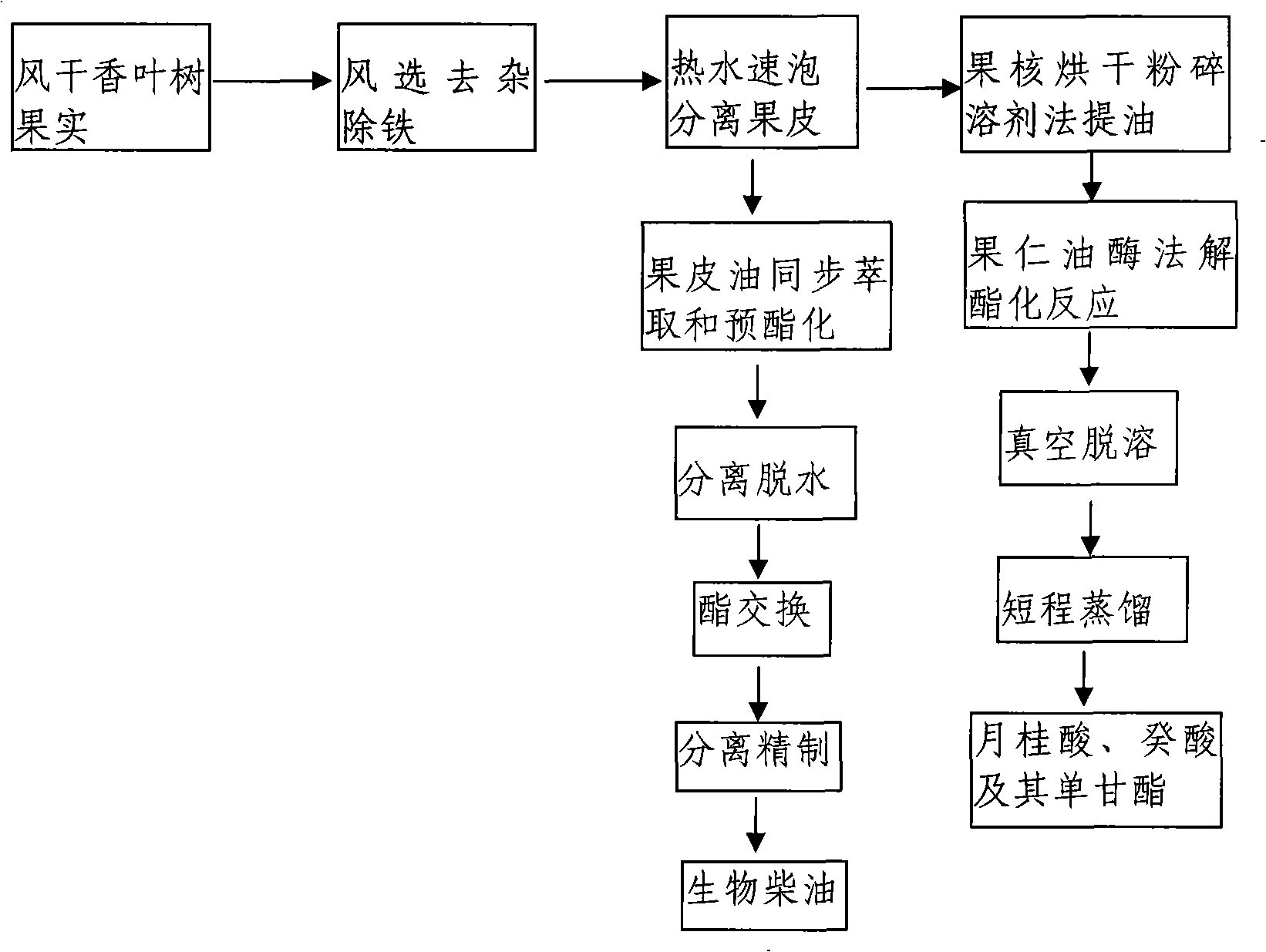

[0053] use as figure 1 The extraction process extracts the fruit of the fragrant leaf tree, and the specific process is as follows:

[0054] The air-dried geranium fruit was selected by winnowing to remove impurities and iron, and the pericarp was quickly soaked in 80°C hot water to separate the peel. The weight ratio of fruit to hot water was 1:6, and the soaking time was 30s. The fruit peels are filtered, pan-milled and ground, and the cores are dried and ground through a 40-mesh sieve.

[0055] Grind the pericarp into a reaction kettle, add methanol, sulfuric acid, etc. to carry out synchronous extraction and pre-esterification of the pericarp oil, the weight ratio of the pericarp and methanol is 1:4, the amount of concentrated sulfuric acid as a catalyst is 0.5% of the dry weight of the pericarp, and the reaction temperature is 70 At ℃, simultaneous extraction and pre-esterification reaction were carried out for 7h. The synchronous extraction and pre-esterification react...

Embodiment 2

[0060] The air-dried geranium fruit was sorted by air to remove impurities and iron, and the pericarp was quickly soaked in hot water at 60°C to separate the peel. The weight ratio of fruit to hot water was 1:7, and the soaking time was 20s. The fruit peels are filtered, pan-milled and ground, and the cores are dried and ground through a 40-mesh sieve.

[0061] Grind the pericarp into a reaction kettle, add ethanol, sulfuric acid, etc. to carry out synchronous extraction and pre-esterification of the pericarp oil, the weight ratio of the pericarp to ethanol is 1:3, the amount of concentrated sulfuric acid as a catalyst is 0.3% of the dry weight of the pericarp, and the reaction temperature is 60 The simultaneous extraction and pre-esterification reaction at ℃ for 5h. The simultaneous extraction and pre-esterification reaction materials are neutralized and dehydrated to a water content of less than 0.5%, the molar ratio of peel oil to ethanol is 1:3, the amount of catalyst NaOH...

Embodiment 3

[0065] The air-dried geranium fruit was selected by winnowing to remove impurities and iron, and the pericarp was quickly soaked in 90°C hot water to separate the peel. The weight ratio of fruit to hot water was 1:5, and the soaking time was 40s. The fruit peels are filtered, pan-milled and ground, and the cores are dried and ground through a 40-mesh sieve.

[0066] Grind the pericarp into a reaction kettle, add isopropanol, sulfuric acid, etc. to carry out synchronous extraction and pre-esterification of the pericarp oil, the weight ratio of the pericarp to isopropanol is 1:5, and the amount of concentrated sulfuric acid as a catalyst is 0.6% of the dry weight of the pericarp , Synchronous extraction and pre-esterification reaction at a reaction temperature of 80° C. for 7 h. Neutralize the synchronous extraction and pre-esterification reaction materials, and dehydrate until the water content is less than 0.5%, the molar ratio of peel oil to isopropanol is 1:5, the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com