Preparation method of blood vessel support or cardiac valve surface coating with good biocompatibility

A biocompatible, vascular stent technology, applied in the field of biochemical modification, can solve the problems of increased vascular stent, social loss, and poor anticoagulant function on the surface of the stent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

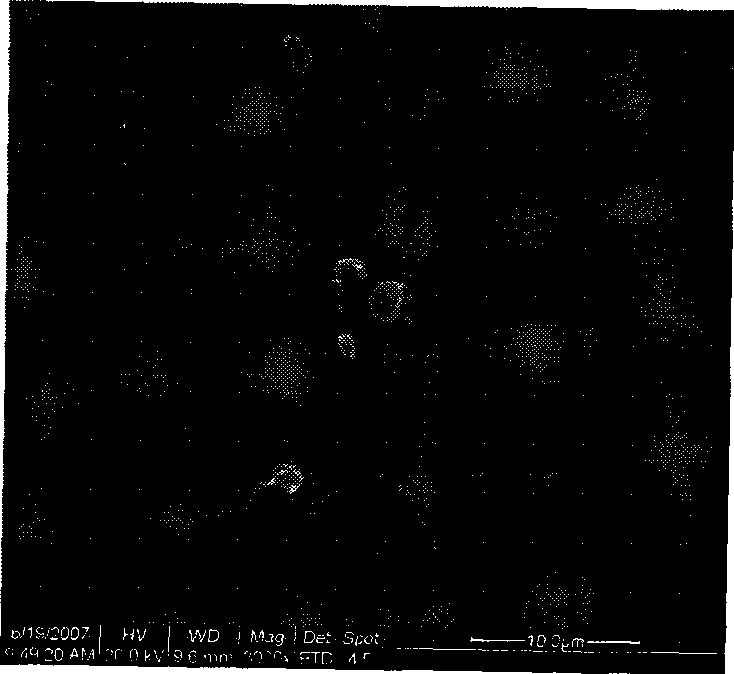

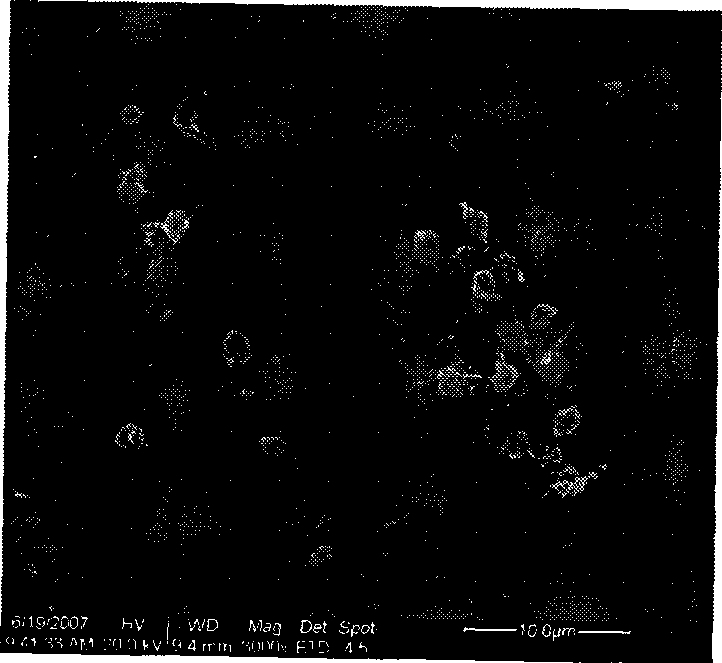

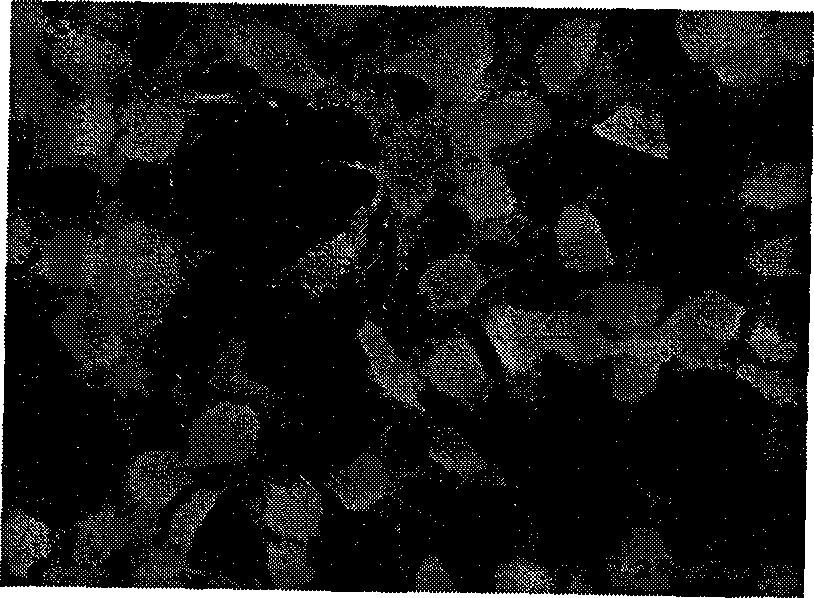

Image

Examples

Embodiment 1

[0024] A preparation method of a vascular stent surface coating with good biocompatibility, the steps are:

[0025] A. Preparation of coating solution Dissolve heparin in deionized water, adjust its pH value to 7, and add endothelial cell growth factor to prepare a heparin / growth factor solution; the heparin concentration in the heparin / growth factor solution in this example 0.5mg / ml, endothelial cell growth factor concentration is 5ng / ml.

[0026] The collagen is dissolved in 0.2 mol / L acetic acid solution to prepare a collagen solution, and the concentration of the collagen solution is 0.5 mg / ml.

[0027] Before performing the dip-coating in the following step B, first immerse the vascular stent in a 0.5mol / L strong alkali solution at 60°C for 3 hours for activation; take it out, ultrasonically clean it with deionized water, and then immerse it in a 0.1mg / ml poly In the polylysine solution, soak for 1 hour, take out the deionized water to clean, blow dry with nitrogen, and ...

Embodiment 2

[0031] A method for preparing a heart valve surface coating with good biocompatibility, the steps are:

[0032] A. Preparation of coating solution Dissolve heparin in deionized water, adjust its pH value to 8, and add endothelial cell growth factor to prepare a heparin / growth factor solution; the heparin concentration in the heparin / growth factor solution is 25 mg / ml, the concentration of endothelial cell growth factor is 50ng / ml.

[0033] The collagen is dissolved in 0.2 mol / L acetic acid solution to prepare a collagen solution, and the concentration of the collagen solution is 5 mg / ml.

[0034]Before the dip coating of the following step B, the heart valve is first activated by immersing it in a 5mol / L strong alkali solution at 80°C for 24 hours; take it out, ultrasonically clean it with deionized water, and then immerse it in 10mg / ml polymer In the lysine solution, soak for 12 hours, take out the deionized water to clean, blow dry with nitrogen, and then carry out the dip...

Embodiment 3

[0038] A preparation method of a vascular stent surface coating with good biocompatibility, the steps are:

[0039] A. Preparation of coating solution Dissolve heparin in deionized water, adjust its pH value to 7.5, and add endothelial cell growth factor to obtain a heparin / growth factor solution; the heparin concentration in the heparin / growth factor solution is 5mg / ml, the concentration of endothelial cell growth factor is 10ng / ml.

[0040] The collagen is dissolved in 0.2 mol / L acetic acid solution to prepare a collagen solution, and the concentration of the collagen solution is 1 mg / ml.

[0041] Before the dip-coating of the following step B, the stent is activated by immersing it in a 3mol / L strong alkali solution at 70°C for 10 hours; take it out, ultrasonically clean it with deionized water, and then immerse it in 2mg / ml polymer In the lysine solution, soak for 4 hours, take out the deionized water to clean, blow dry with nitrogen, and then carry out the dip coating i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com