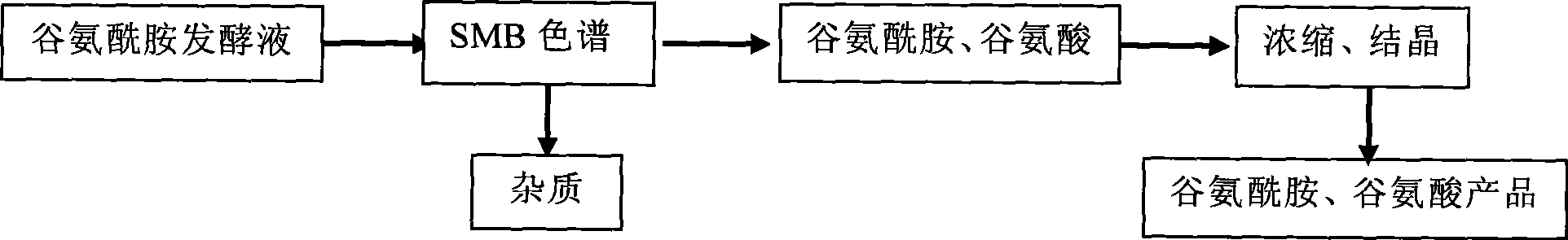

Method for separating and purifying glutamine and aminoglutaric acid from glutamine fermentation liquor

A glutamine and fermentation broth technology, applied in the field of simulated moving bed chromatographic separation, can solve problems such as inability to separate glutamine, low yield of glutamine and glutamic acid products, affecting product quality, etc., and achieve production cost Low cost, small production site and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: synthetic resin

[0035]First synthesize two kinds of special resins (metal ion type chelating resin and acid radical ion type chelating resin) specially used for adsorption and separation of glutamine;

[0036] Metal ion-type chelating resins use acidic macroporous or gel resin as a carrier to chelate metal ions, use the affinity between the acidic resin and metal ions to adsorb the metal ions on the surface of the acidic macroporous resin, and use the A linking agent is used to fix it on the matrix resin; the amount of the crosslinking agent used is 4% to 20% of the weight of the acidic macroporous resin, and the best is 10% to 14%.

[0037] Metal ion is Al 3+ or Ba 2+ or Bi 3+ or Ca 2+ or Co 2+ or Co 3+ or Cu 2+ or Fe 2+ or Fe 3+ or K + or Mg 2+ or Na + or Ni 3+ or Pb 2+ or Sb 3+ or Sn 2+ or Zn 2+ , which is used in the form of a salt or oxide of a corresponding metal ion that can be dissolved under neutral or alkaline conditions, and t...

Embodiment 2

[0052] Embodiment 2: separation and purification

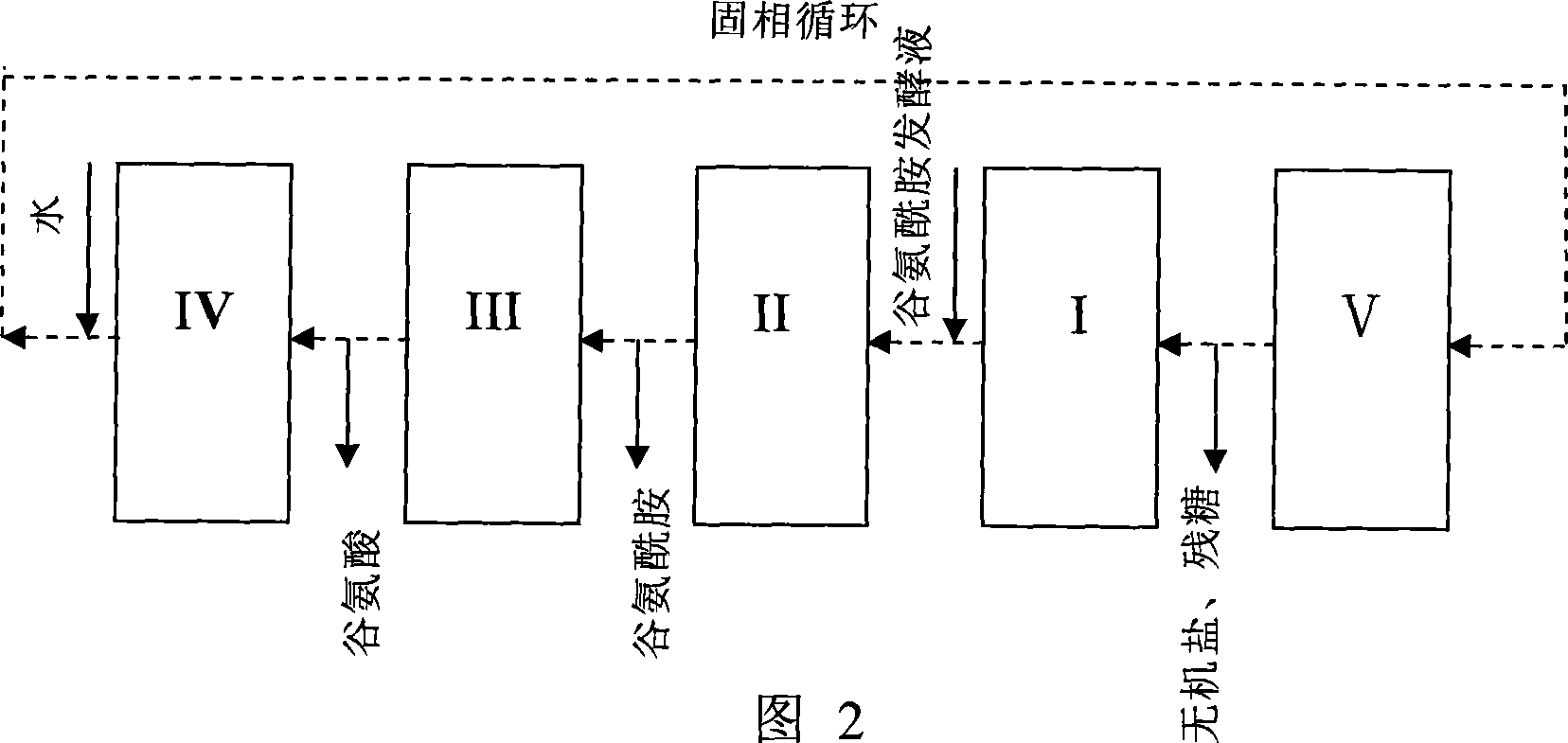

[0053] The fixed bed equipped with the above-mentioned special resins uses the simulated moving bed technology to separate and purify glutamine from the fermentation broth to obtain pure glutamine and glutamic acid products;

[0054] Simulated moving bed technology: In the simulated moving bed chromatographic separation device, the above-mentioned special resin is used as the stationary phase adsorbent, and the difference in affinity between the functional group and glutamine, glutamic acid and other impurities is used to realize glutamine, glutamic acid Complete separation from impurities such as inorganic salts and residual sugar; water is used as the eluent, the separation temperature is 35°C-95°C, and the optimum separation temperature is 50°C, and the feeding and discharging operations are carried out continuously to obtain three Class discharge components, the first category is the components with a glutamine purity of 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com