Method for preparing high specific surface area nano alumina material

A technology of nano-alumina and high specific surface area, applied in the field of preparation of nano-alumina materials, can solve the problems of high cost, low specific surface area of alumina, complicated process, etc., and achieve low cost, high uniformity and stability, production simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

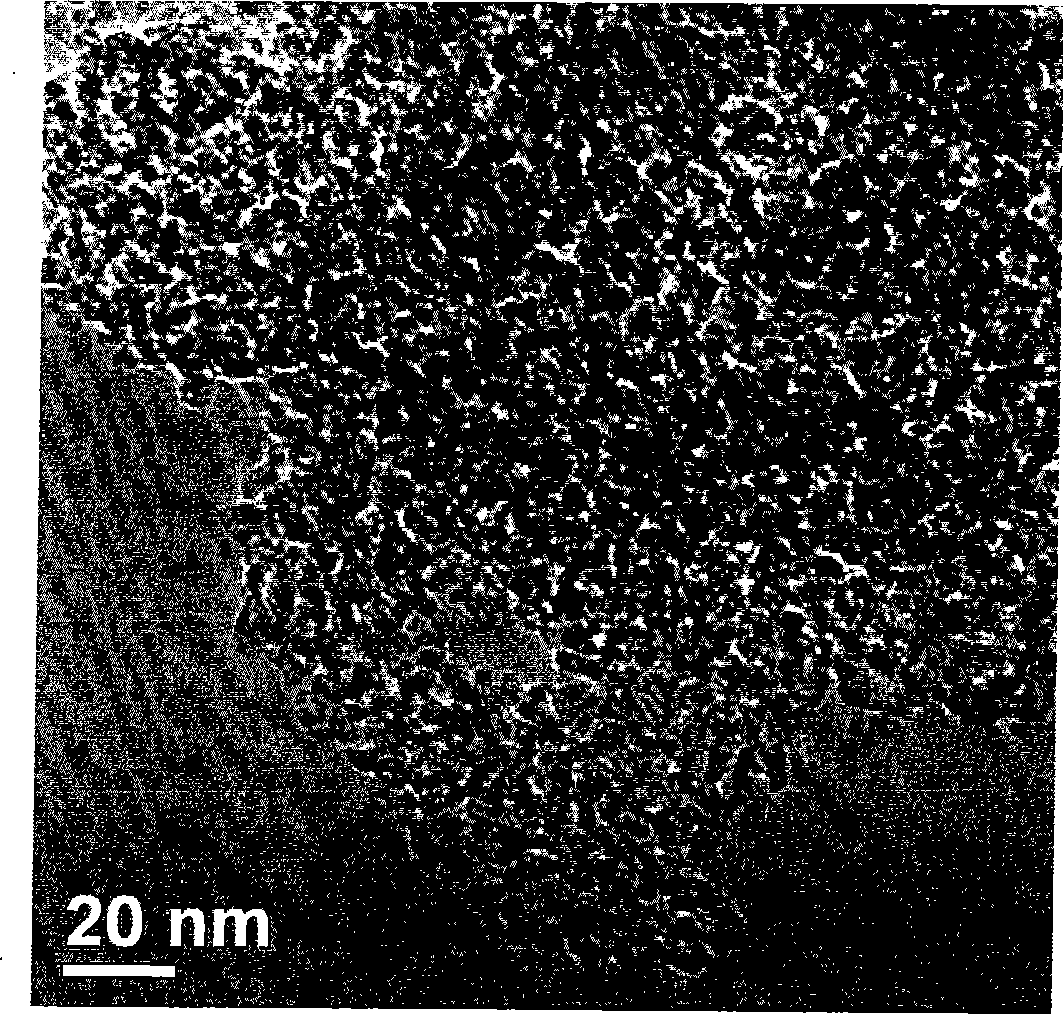

Image

Examples

Embodiment 1

[0033] Adopt the method for preparing high specific surface area nano-alumina material of the present invention, the specific preparation steps of the gamma-alumina material obtained are as follows:

[0034] 1) Mix 290ml of cyclohexane, 120ml of polyethylene glycol octylphenyl ether and 100ml of n-butanol and stir evenly, divide into two parts of equal volume;

[0035]2) Add 100ml of 1.0M aluminum nitrate aqueous solution dropwise to a part of the above-mentioned organic phase at a rate of 10ml / min, stir while adding dropwise and control the mol ratio of water to surfactant to be 15 to form an aluminum nitrate microemulsion;

[0036] 3) Add 100ml of 2.0M ammonium carbonate aqueous solution dropwise to another part of the above-mentioned organic phase at a rate of 10ml / min, stir while adding dropwise and control the mol ratio of water to surfactant to be 15 to form an ammonium carbonate microemulsion ;

[0037] 4) At 25°C, add the ammonium carbonate microemulsion dropwise at a...

Embodiment 2

[0042] 290ml of cyclohexane, 120ml of polyethylene glycol octylphenyl ether and 100ml of n-butanol were mixed and stirred evenly to form a uniform organic phase, which was divided into two parts of equal volume. Add 100ml of 1.0M aluminum nitrate aqueous solution dropwise to a portion of the above-mentioned organic phase at a rate of 10ml / min, stir while adding dropwise and control the molar ratio of water to surfactant to be 15 to form an aluminum nitrate microemulsion; 100ml of ammonium carbonate aqueous solution of 2.0M is added dropwise in another part of above-mentioned organic phase at the speed of / min, stirs while adding dropwise and controls the mol ratio of water and tensio-active agent to be 15, forms ammonium carbonate microemulsion. At 25°C, the aluminum nitrate microemulsion was added dropwise at a rate of 10ml / min to the stirring ammonium carbonate microemulsion until the pH value was 9, and aged at 60°C for 48 hours after reacting for 3h. Filter the aged slurry...

Embodiment 3

[0044] Mix 290ml of cyclohexane, 120ml of polyethylene glycol octylphenyl ether and 100ml of n-butanol and stir evenly, add 100ml of 1.0M aluminum nitrate aqueous solution to the above organic phase dropwise at a rate of 10ml / min, dropwise Stir while adding and control the molar ratio of water to surfactant to be 15 to form an aluminum nitrate microemulsion; add 100ml of 2.0M ammonium carbonate aqueous solution dropwise at a rate of 10ml / min to the stirring aluminum nitrate microemulsion at 25°C In the emulsion, until the pH value is 9, after 3 hours of reaction, it is aged at 60°C for 48 hours. Filter the aged slurry, wash the filter cake with 1000ml of deionized water and 300ml of absolute ethanol, then vacuum-dry at 120°C for 12 hours, and bake at 500°C for 3 hours to obtain the high specific surface area nano-alumina material prepared in this example .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com