Method for preparing fructus arctii aglycone

A technology of arctigenin and arctiin, which is applied in the field of preparation of arctigenin, can solve the problems of complicated process and high cost in the separation and extraction process, and achieve the effect of being environmentally friendly, easy to operate, and realizing large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] See Figure 1 for the process flow chart.

[0031] Incline cultivation:

[0032] Preparation of slant medium: Weigh 200g of potatoes, wash, peel and chop them, add 1000ml of water to boil for half an hour, filter with gauze, add 20g of glucose and 20g of agar, fully dissolve, filter with gauze while hot, and pack into test tubes, 1×10 5 Pa sterilize for 30 minutes, place on a slant to cool down, and obtain a slant medium.

[0033] Aspergillus niger CGMCC No.2594 was inoculated into slant medium and cultured at 30°C for 7 days to obtain slant strains.

[0034] Liquid fermentation:

[0035] Liquid fermentation medium preparation (final concentration composition): rice straw powder 50g / L, wheat bran 15g / L, barley flour 15g / L, (NH 4 ) 2 SO 4 10g / L, KH 2 PO 4 0.5g / L, MgSO 4 ·7H 2 O 0.5g / L, initial pH5.0.

[0036] Preparation of β-glucosidase enzyme liquid: inoculate 1ml (the number of spores is about 125 / ml) spore suspension obtained by washing CGMCC No.2594 slant...

Embodiment 2

[0041] According to the method described in Example 1, CGMCC No.2594 cell slant was obtained, and a liquid fermentation medium was prepared.

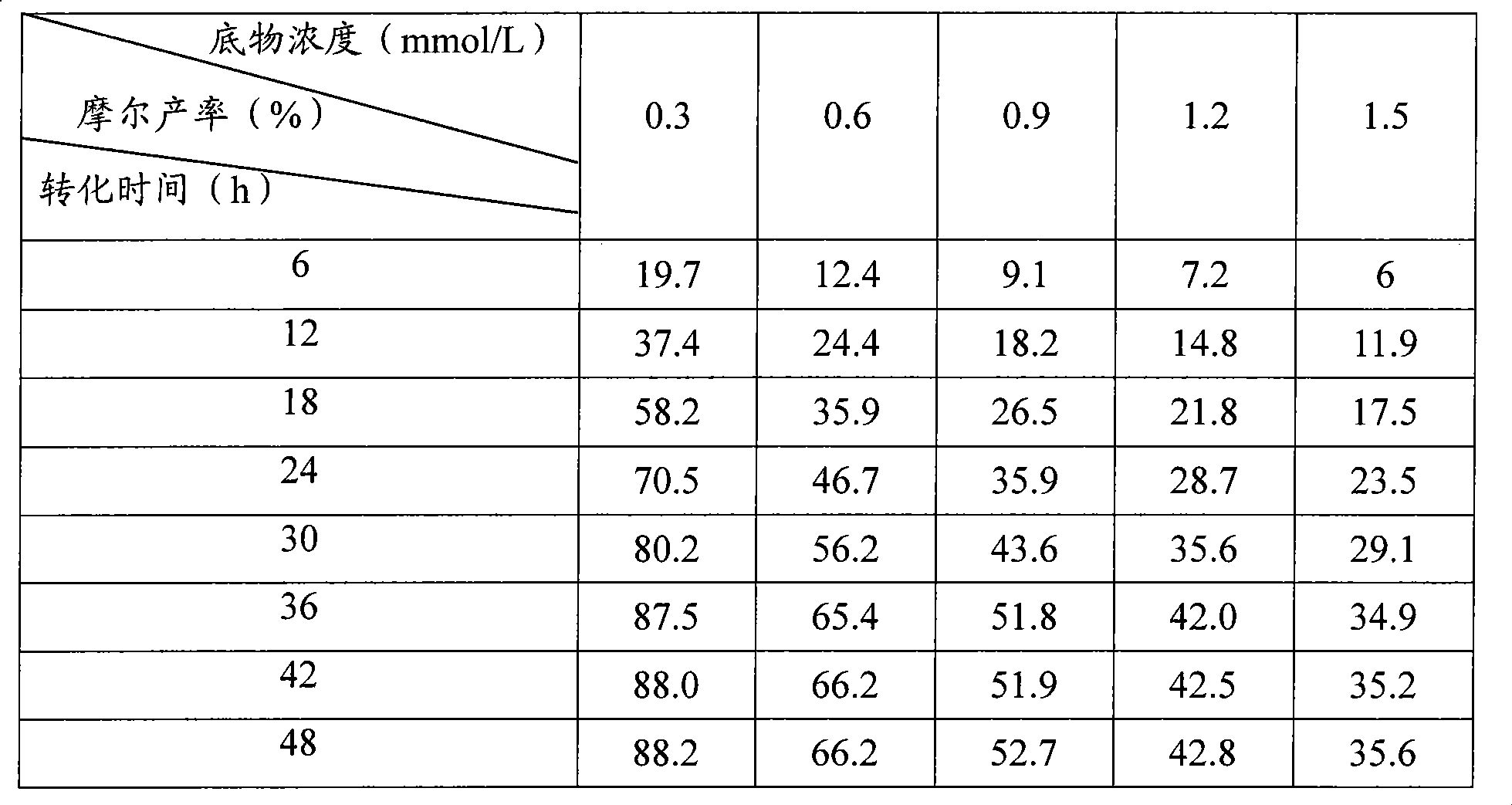

[0042] Preparation of β-glucosidase enzyme liquid: inoculate 1ml (the number of spores is about 125 / ml) spore suspension obtained by washing CGMCC No.2594 slant strain with physiological saline into a 500ml Erlenmeyer flask containing 200ml fermentation medium Shake at 30°C (150r / min) for 7 days, filter the obtained fermentation broth, adjust the initial pH of the filtrate to 6.0 with HCl and NaOH, and dilute it to 250ml with sterile water as a β-glucosidase enzyme solution for later use. The enzyme activity of the obtained β-glucosidase enzyme liquid is 68U / ml.

[0043] Preparation of the substrate solution: Weigh the arctiin standard substance and dissolve it in 100ml sterile water to prepare 0.6, 1.2, 1.8, 2.4 and 3.0mmol / L substrate solutions respectively.

[0044] Take 10ml of the enzyme solution and mix them with 10ml of the abov...

Embodiment 3

[0048] According to the method described in Example 1, CGMCC No.2594 cell slant was obtained, and a liquid fermentation medium was prepared.

[0049] Preparation of β-glucosidase enzyme liquid: inoculate 1ml (the number of spores is about 125 / ml) spore suspension obtained by washing CGMCC No.2594 slant strain with physiological saline into a 500ml Erlenmeyer flask containing 200ml fermentation medium Shaking (150r / min) at 30°C for 7 days, the obtained fermentation broth was filtered, and the initial pH values of the filtrate were adjusted to 3, 4, 5, 6, 7, 8, 9, 10 and 11 with HCl and NaOH, respectively. The bacterial water was adjusted to 250ml as β-glucosidase enzyme solution for later use. The enzyme activities of the obtained β-glucosidase enzyme solutions were 38, 49, 56, 68, 65, 61, 56, 45 and 35 U / ml, respectively.

[0050] Preparation of the substrate solution: Weigh the arctiin standard substance and dissolve it in 100ml sterile water to prepare 0.6mmol / L substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com