Method for producing fluorescent polypropylene fibers by utilizing organic fluorescent compound

A fluorescent compound, polypropylene fiber technology, applied in chemical instruments and methods, fiber chemical characteristics, single-component polyolefin rayon, etc., can solve the lack of organic solid fluorescent materials, large amount of fluorescent powder added, and short service life and other problems, to achieve the effect of good solid-state light-emitting performance, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

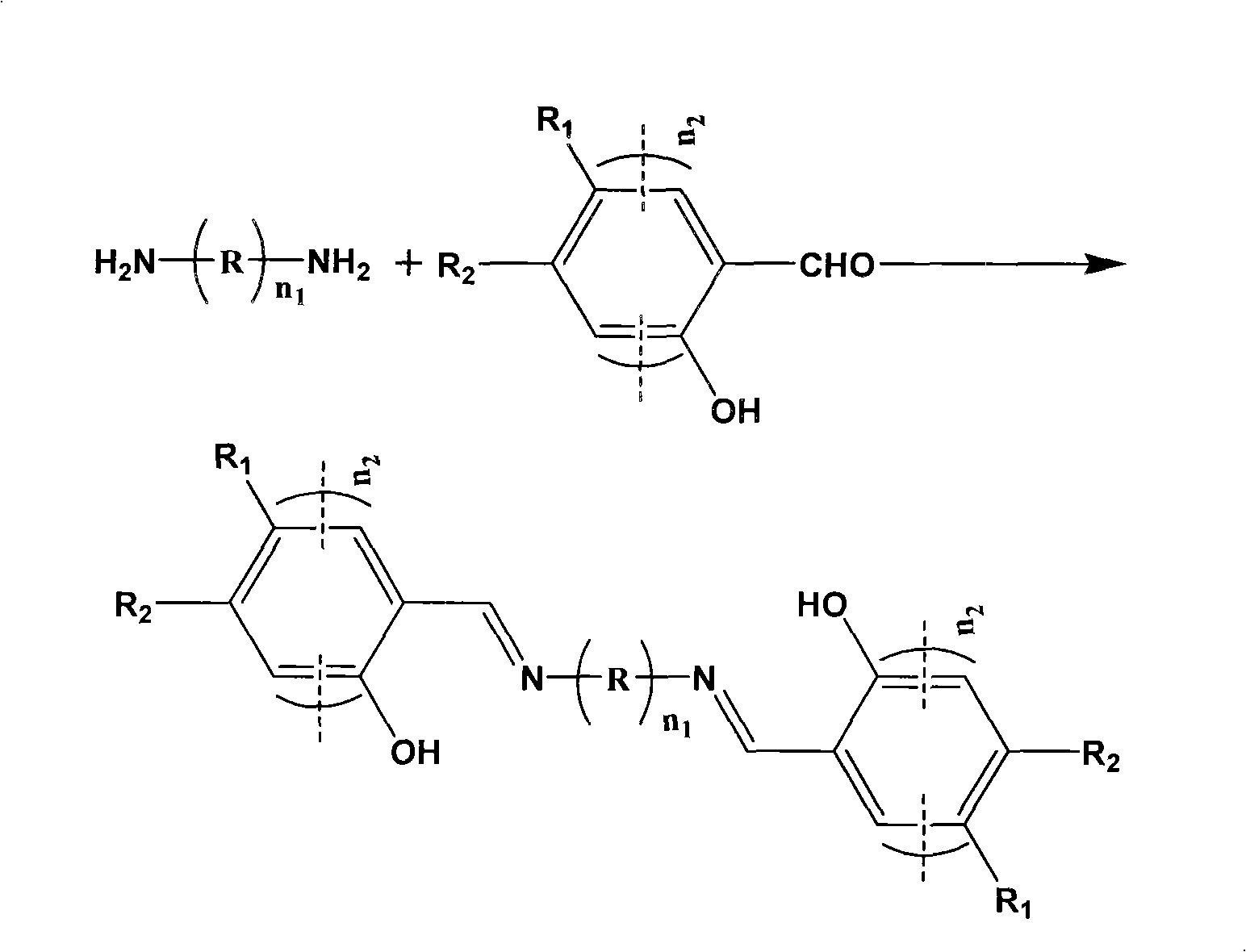

[0058] The synthetic routes of fluorescent compounds are shown in Table 1.

[0059]

[0060] Table 1

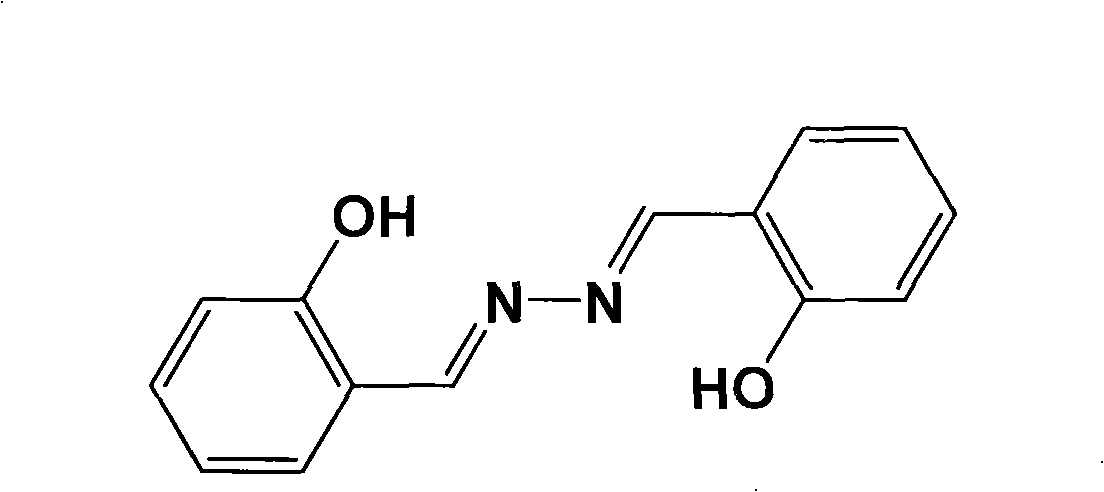

[0061] (1) Synthesis of Fluorescent Compound 1 (n 1 =0, n 2 =1, R 1 =R 2 =H)

[0062] Weigh 1.20g of salicylaldehyde and dissolve it in absolute ethanol, heat it to 80°C in a water bath, slowly add 0.16g of 85wt% hydrazine hydrate dropwise, and condense and reflux for 1.5h to obtain a yellow precipitate. After recrystallization, it was filtered and dried to obtain the target compound 1 as a bright yellow solid with a mass of 1.20 g (yield 88.6%).

[0063] Mass spectrum (EI): m / z240

[0064] Melting point: 219℃

[0065] H NMR 1 H-NMR (400MHz, CDCl 3 , 25°C, TMS): δ=11.12 (s, 2H), 9.00 (s, 2H), 7.71-7.68 (m, 2H), 7.41 (m, 2H), 6.97 (m, 4H). Elemental Analysis C 14 H 12 N 2 O 2 (240.09) calcd: C, 69.99; H, 5.03; N, 11.66. Measured: C, 70.05; H, 5.04; N, 11.61.

[0066] (2) Synthesis of compound 2 (n 1 =0, n 2 =1, R 1 =-NO 2 , R 2 =H)

[0067] The prepara...

Embodiment 2

[0107] Preparation of luminescent polypropylene fibers

[0108] Raw material: polypropylene 200g fluorescent compound 2g

[0109] Preparation method: the above-mentioned raw materials are mixed uniformly and then melt-blended, extruded and spun with a multifilament 400 melt spinning machine. The spinning speed was 400m / min, the spinning temperature was 270°C, and the post-drawing ratio was 2.8 times.

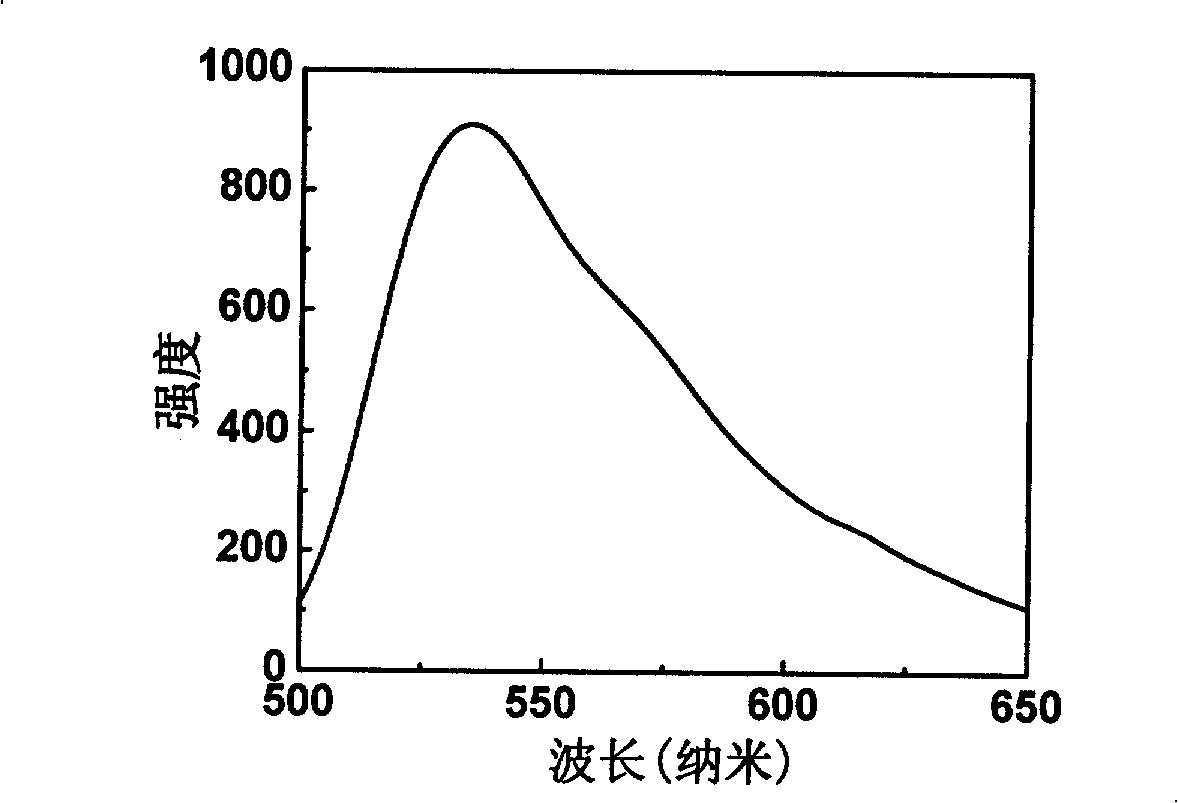

[0110] Result: The specification of the drawn filament of the luminescent fiber is 68dtex / 18f, the strength is 3.83cN / dtex, and the maximum emission wavelength is 534nm.

Embodiment 3

[0112] Preparation of luminescent polypropylene fibers

[0113] Raw material: polypropylene 200g fluorescent compound 4g

[0114] Preparation method: the above-mentioned raw materials are mixed uniformly and then melt-blended, extruded and spun with a multifilament 400 melt spinning machine. The spinning speed was 400m / min, the spinning temperature was 270°C, and the post-drawing ratio was 2.8 times.

[0115] Result: The specification of the drawn filament of the luminescent fiber is 64dtex / 18f, the strength is 3.59cN / dtex, and the maximum emission wavelength is 534nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com