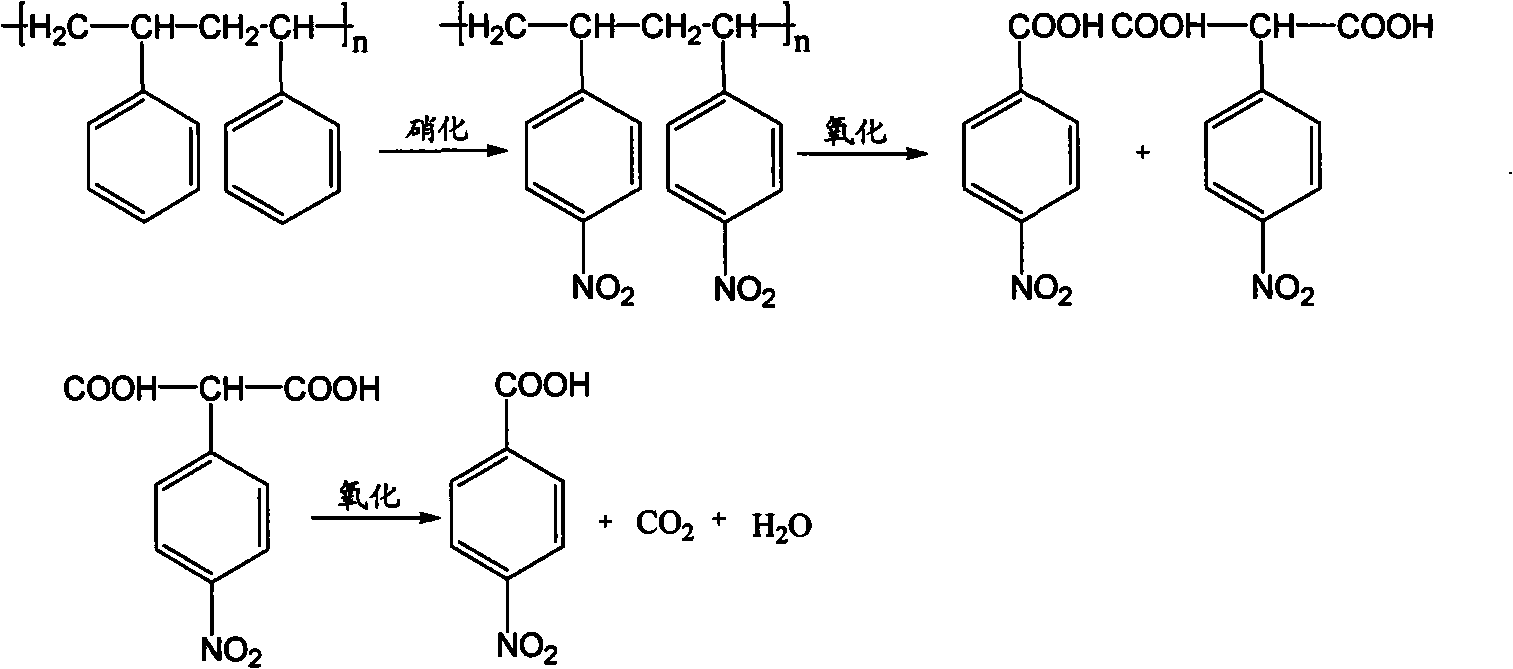

Method for preparing p-nitrobenzoic acid from waste polystyrene

A technology for waste polystyrene and p-nitrobenzoic acid is applied in the preparation of nitro compounds, organic chemistry, etc., and can solve the problems of unsatisfactory results, long process steps, low purity, etc., to increase yield and reduce production costs. , to avoid the effect of multi-step operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the preparation of catalyst I (Fe 2+ and Zn 2+ complexed to sepiolite).

[0032] Using the hydrothermal method, in 1L of water, put 100g of sepiolite particles and 1mol / L of FeCl 2 , reacted at 230°C for 8 hours to make Fe 2+ Precipitate on the sepiolite carrier; take out the sepiolite and dry it at 120°C, and keep it at 50°C for 5 hours; put the complexed Fe 2+ Put the sepiolite containing 0.25mol / L ZnCl 2 In the water, the ratio of sepiolite particles to water is 100g / L, react at 260°C for 8 hours, and precipitate Zn 2+ ; After taking out the sepiolite and drying it at 120°C, it was kept at 50°C for 5 hours to prepare the catalyst I.

Embodiment 2

[0033] Embodiment 2: the preparation of catalyst II (Fe 2+ and Ni 2+ complexed to sepiolite).

[0034] Using the hydrothermal method, put 150g of sepiolite particles and 1mol / L of FeCl in 1L of water 2 , reacted at 240°C for 10 hours to make Fe 2+ Precipitate on the sepiolite carrier; take out the sepiolite and dry it at 130°C, and keep it at 50°C for 8 hours; put the complexed Fe 2+ Put the sepiolite containing 1mol / L NiCl 2 In the water, the ratio of sepiolite particles to water is 150g / L, react at 270°C for 10 hours, precipitate Ni 2+ ; After taking out the sepiolite and drying it at 120°C, it was kept at 50°C for 6 hours to prepare Catalyst II.

Embodiment 3

[0036] After defoaming the ordinary waste polystyrene organic solvent, use a pulverizer to pulverize to obtain polystyrene powder, add 1g of the above powder to the reaction bottle of the microwave reactor, add nitric acid by 9.5 times the mass of polystyrene, and press polystyrene 5% of the mass of styrene is added to Catalyst I, and then put into a magnetic rotor to mix and react. The reaction time of the microwave reactor is set to 30min, the set reaction temperature is 200°C, the set reaction pressure is 2.0MPa, and the reaction power is 1200W. After the reaction is over, pour it into a beaker while it is hot, and cool to room temperature to precipitate p-nitrobenzoic acid. Filter with a sand core funnel, wash with distilled water to remove residual acid, and then filter. Pour heated ethanol into the funnel to fully rinse the product, and then pour it into a beaker. Then heated to boiling and stirred with a glass rod for about 10min, then filtered while hot to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com