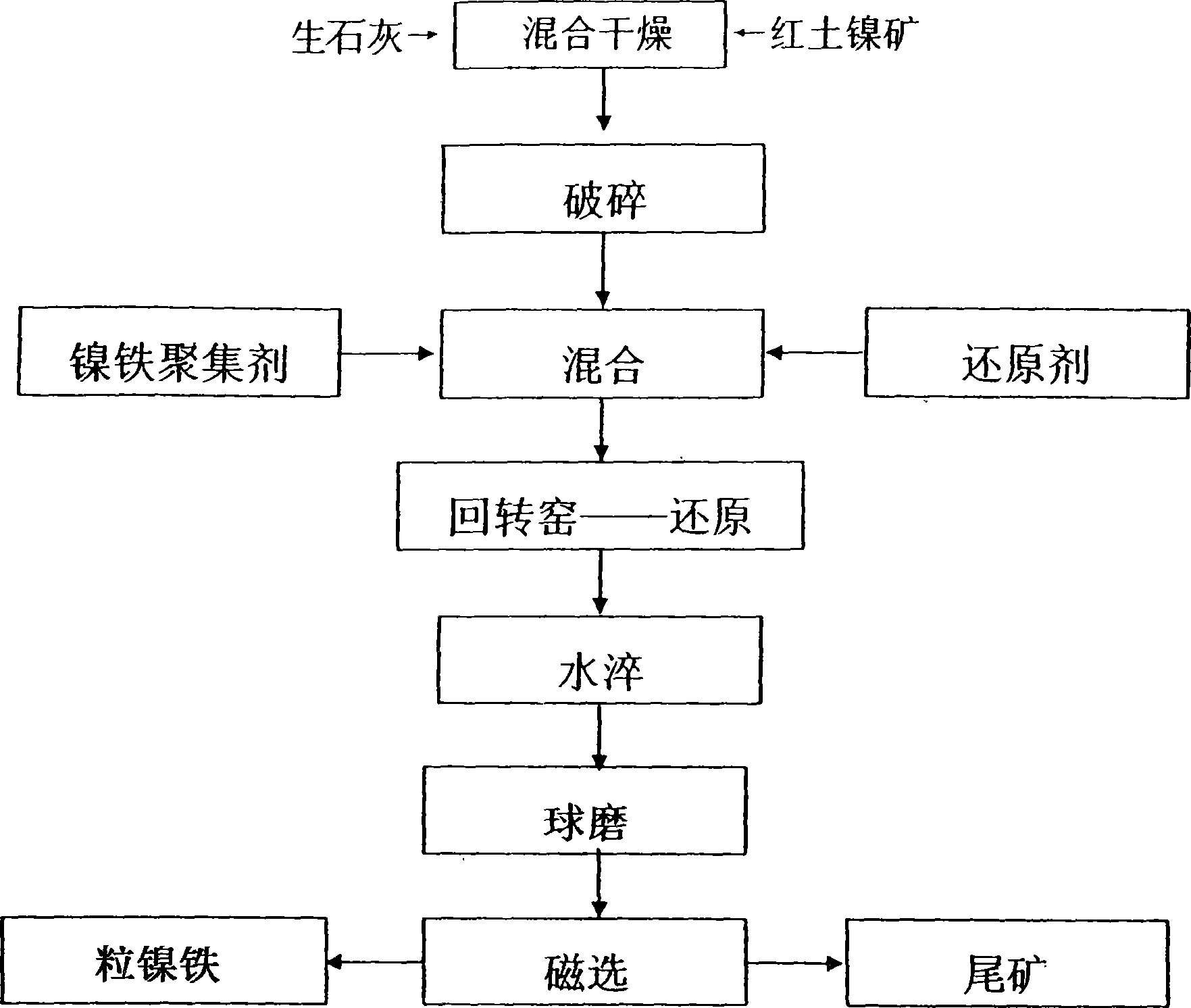

Method for directly reducing grain nickel iron in rotary kiln by using laterite nickle mine

A technology of laterite nickel ore and rotary kiln, applied in chemical instruments and methods, magnetic separation, solid separation and other directions, can solve the problems of complex processing technology, affecting normal production and high production cost, achieving simple production technology, improving nickel grade and Recovery rate, the effect of short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The water-containing laterite nickel ore powder (Ni1.41, Tfe8.8%) is mixed with 5% calcium quicklime and dried, crushed to less than 5mm, and 8% of the original ore weight is added with carbonaceous reducing agent and 7% of nickel iron aggregate The agent is evenly mixed and sent directly to the rotary kiln for reduction roasting, the temperature is controlled at 1260°C, and the reduction time is 3 hours. After reduction roasting, it is quenched with water, crushed and ball milled, and then magnetically separated by a 2000 Gauss magnetic separator to obtain nickel-iron particles. The nickel grade can reach 15.2%, and the nickel recovery rate can reach 90.1%.

Embodiment 2

[0017] Mix the water-containing laterite nickel ore (Ni1.68, TFe 10.2%) with 7% calcium quicklime and dry it, crush it to less than 5mm, add 9% of the original ore weight carbonaceous reducing agent, and 8% nickel-iron aggregates to mix It is uniform and directly enters the rotary kiln for reduction and roasting. The temperature is controlled at 1280℃. After reduction and roasting, it is water quenched, crushed, ball milled, and then magnetically separated by a 2200 Gauss magnetic separator to obtain granular nickel iron. The nickel grade can reach 17.6%. The recovery rate reached 90.5%.

Embodiment 3

[0019] The hydrated laterite nickel ore (Ni1.76, TFe11.0%) is mixed and dried with 6% magnesium quicklime, crushed to less than 5mm, and 7% carbonaceous reducing agent by weight of the original ore and 6% nickel-iron aggregates are added The mixture is uniformly mixed and directly enters the rotary kiln for reduction and roasting. The temperature is controlled at 1300℃. After reduction and roasting, it is quenched by water, crushed, ball milled, and then magnetically separated by a 2500 Gauss magnetic separator to obtain nickel-iron particles with a nickel grade of 18.0%. The recovery rate of nickel reaches 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com