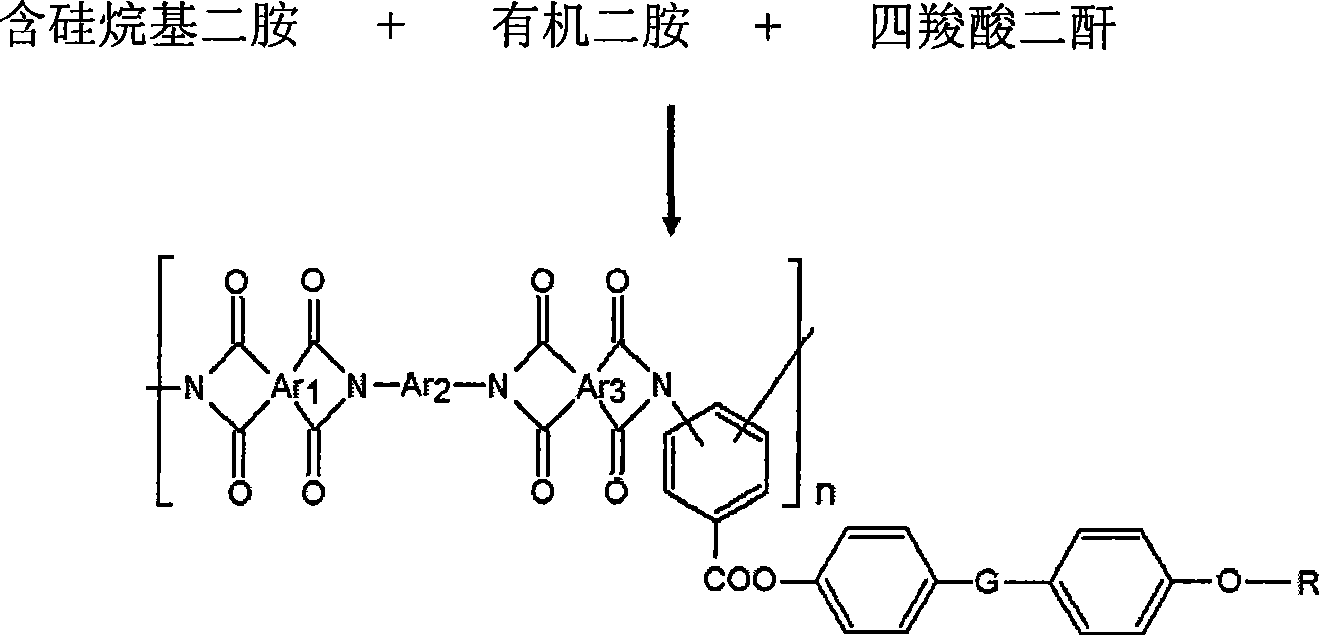

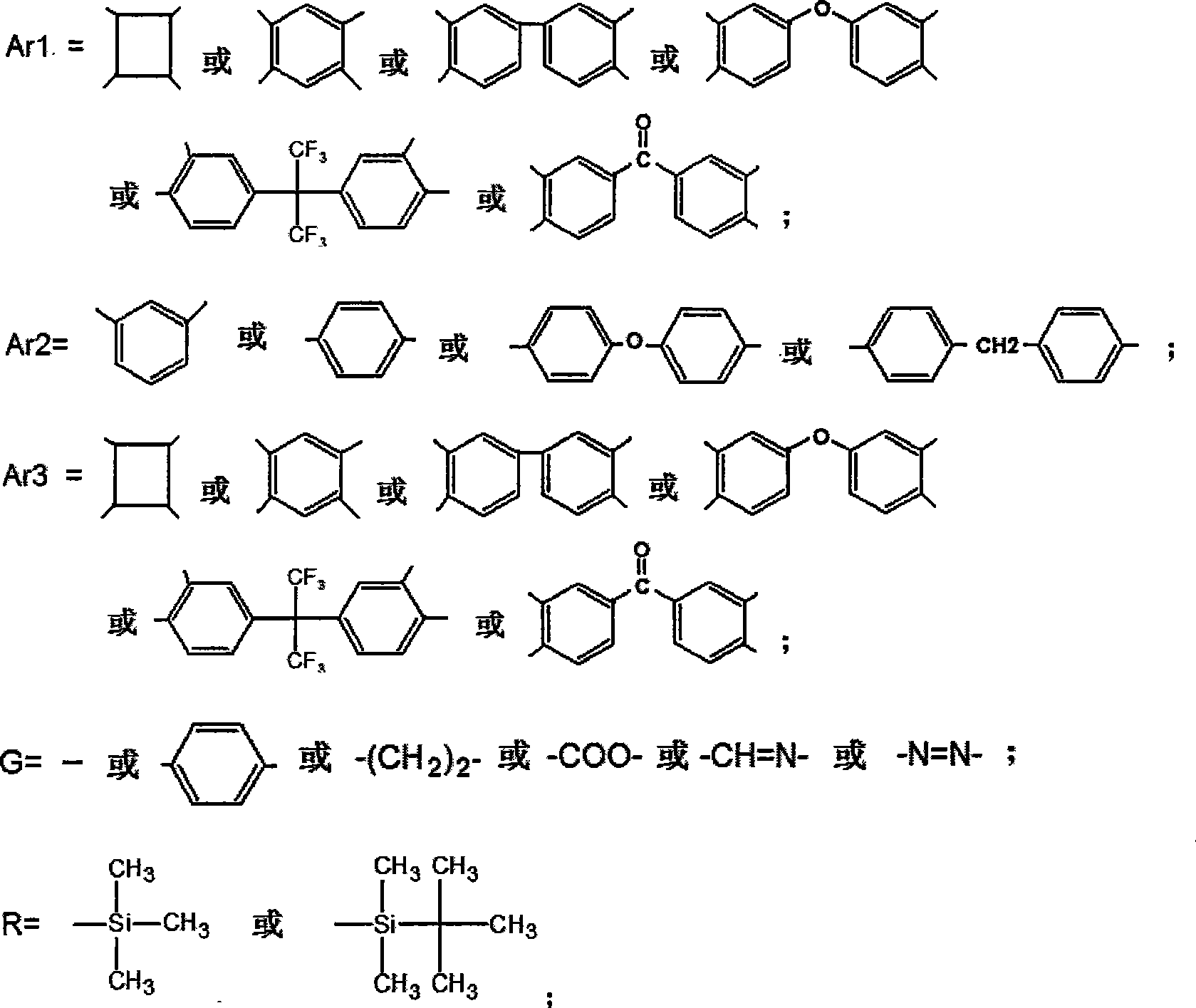

Big tilt angle silicon-containing alkyl polyimide liquid crystal orientation film and method for making same

A technology containing silane-based polyimide and silane-based polyimide, which can be applied in nonlinear optics, instruments, optics, etc., can solve the problems of lack of molecular structure tunability, few types of synthetic raw materials, etc., and achieve liquid crystal orientation. Good uniformity, low cost and good coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

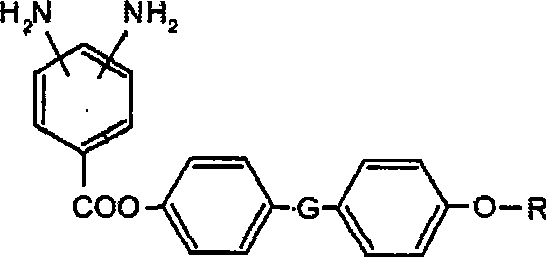

[0039] (1) The chemical reaction formula of 4'-(tert-butyldimethylsilyloxy) biphenyl-3,5-diaminobenzoate (DPA) is as follows:

[0040]

[0041]

[0042] a. Preparation of 3,5-dinitrobenzoyl chloride

[0043] Add 21.2g (0.1mol) of 3,5-dinitrobenzoic acid into a three-necked flask with a stirrer, a thermometer and a reflux condenser, inject 100ml of thionyl chloride (SOCl 2 ), heated to reflux under stirring, when no tail gas was emitted, excess SOCl was evaporated at normal pressure 2 , to obtain 3,5-dinitrobenzoyl chloride.

[0044] b. Preparation of 4'-(hydroxy)biphenyl-3,5-dinitrobenzoate

[0045] The above 23.05 g (0.1 mol) of 3,5-dinitrobenzoyl chloride was dissolved in 50 ml of tetrahydrofuran (THF) for use. Another 24g (0.13mol) of 4,4'-dihydroxybiphenyl was dissolved in 100ml of THF, and 8ml (0.1mol) of pyridine was added as an acid absorbing agent, and the above acid chloride solution was slowly added dropwise to 4,4 '-dihydroxybiphenyl THF solution, reacted ...

Embodiment 2

[0068] 3mol 4"-(tert-butyldimethylsilyloxy)benzoyloxyphenyl-3,5-diaminobenzoate (EPA), 7mol ODA and 10mol 3,3',4,4' - Dissolve biphenyltetracarboxylic dianhydride (BPDA) in 50mol NMP, react under nitrogen protection at a temperature of 10°C for 24 hours, and dilute the formed polymer solution to 5% with γ-butyrolactone to obtain a polyamic acid solution. Film is coated in the same way in Example 1 (3), then solidified at a temperature of 250°C for 1 hour to obtain a polyimide liquid crystal alignment film and make a liquid crystal cell.Adopt the crystal rotation method to test the pretilt angle, and confirm the liquid crystal under a polarizing microscope The uniformity of liquid crystal orientation in the cell, the results are shown in Table 1.

Embodiment 3

[0070] 4mol 4'-(tert-butyldimethylsilyloxy)biphenyl-3,5-diaminobenzoate (DPA), 6mol p-phenylenediamine and 10mol 3,3',4,4' Dissolve biphenyltetracarboxylic dianhydride (BPDA) in 50 mol of NMP, react under nitrogen flow at a temperature below 10°C for 12 hours, and dilute the formed polymer solution to 5% with NMP to obtain a polyamic acid solution. The film was coated in the same manner as in Example 1 (3), and then cured at a temperature of 230° C. for 3 hours to obtain a polyimide liquid crystal alignment film, which was then fabricated into a liquid crystal cell. The pretilt angle was tested by the crystal rotation method, and the uniformity of the liquid crystal orientation in the liquid crystal cell was confirmed under a polarizing microscope. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com