Bacillus coli alcoholic fermentation engineering bacterium and uses thereof

A technology of Escherichia coli and ethanol fermentation, applied in the direction of fermentation, application, genetic engineering, etc., can solve problems such as inappropriateness, achieve the effect of reducing investment and increasing ethanol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Preparation of ethanol-resistant Escherichia coli ethanol fermentation engineering bacteria

[0024] A. Screening of Escherichia coli ethanol-tolerant mutants

[0025] Escherichia coli JM109 was cultivated in LB medium, and after growing to the logarithmic phase, it was transferred to the LB medium culture containing 10g / L, 20g / L, 30g / L, 40g / L and 50g / L ethanol. um of filter membrane and join in the LB substratum), the ethanol concentration of 30g / L has obviously suppressed the growth of escherichia coli JM109. The JM109 grown in LB containing 30g / L ethanol was transferred through successive generations, and after each transfer three generations, it was applied to a solid LB medium containing isopropanol (which is not volatile and can maintain the selective pressure of ethanol) On the top, select a single colony that grows rapidly and continue to transfer.

[0026] Taking JM109 grown in ethanol-free LB medium as a control, calculate the number of colonies an...

Embodiment 2

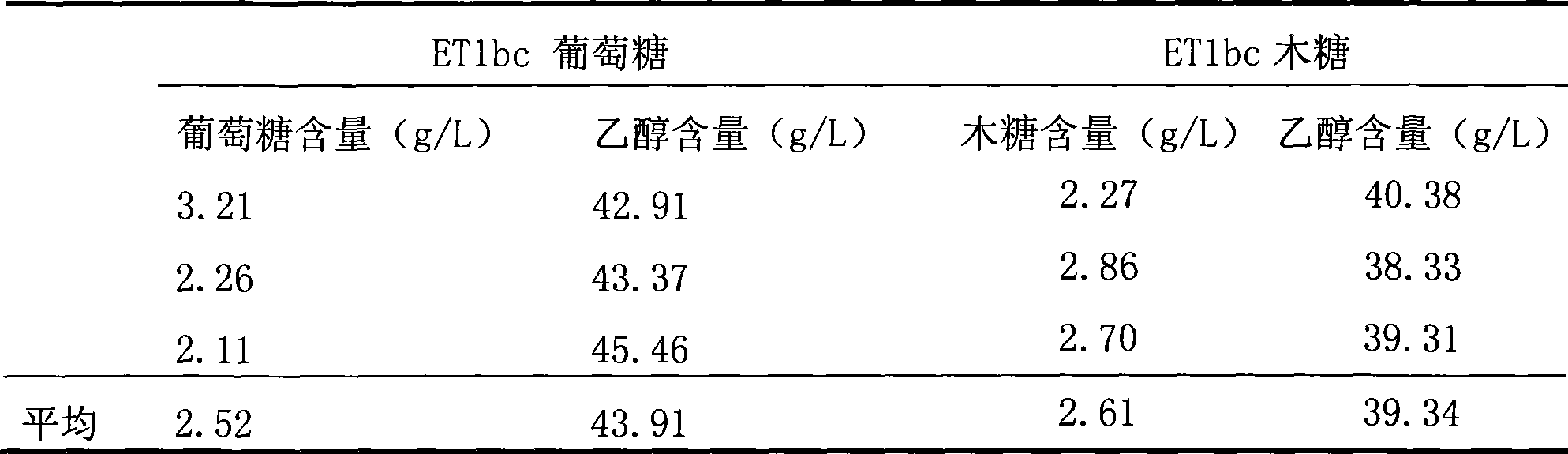

[0071] Example 2 Fermentation of engineering strain ET1bc to produce ethanol

[0072] 1. Culture conditions

[0073] 1.1 Medium composition

[0074] Glucose 10%, yeast extract 0.5%, sodium chloride 1.0%, peptone 1.0%, phosphate buffer pH7.0;

[0075] Xylose 10%, yeast extract 0.5%, sodium chloride 1.0%, peptone 1.0%, phosphate buffer pH 7.0;

[0076] 1.2 Culture and fermentation conditions

[0077] Inoculate ET1bc into LB medium and culture to OD 600 =When around 0.2, add 1.0mM IPTG to induce, when ET1bc grows to OD 600 = 1.0, the bacteria were collected by centrifugation, inoculated into the fermentation medium described in 1.1, and made OD after inoculation 600 The value is about 1.0, anaerobic culture at 37 degrees Celsius.

[0078] 2. Determination of residual sugar in fermentation broth

[0079] Use high-performance liquid chromatography to detect the residual sugar content in the fermentation broth, and the measurement conditions are as follows, detector: Waters41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com