Microwave assisted method for rapidly synthesizing ordered mesoporous carbon

A microwave-assisted, mesoporous carbon technology, which is applied in the field of carbon nanomaterial preparation technology, can solve the problems of consuming a lot of time and energy, and not forming a system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

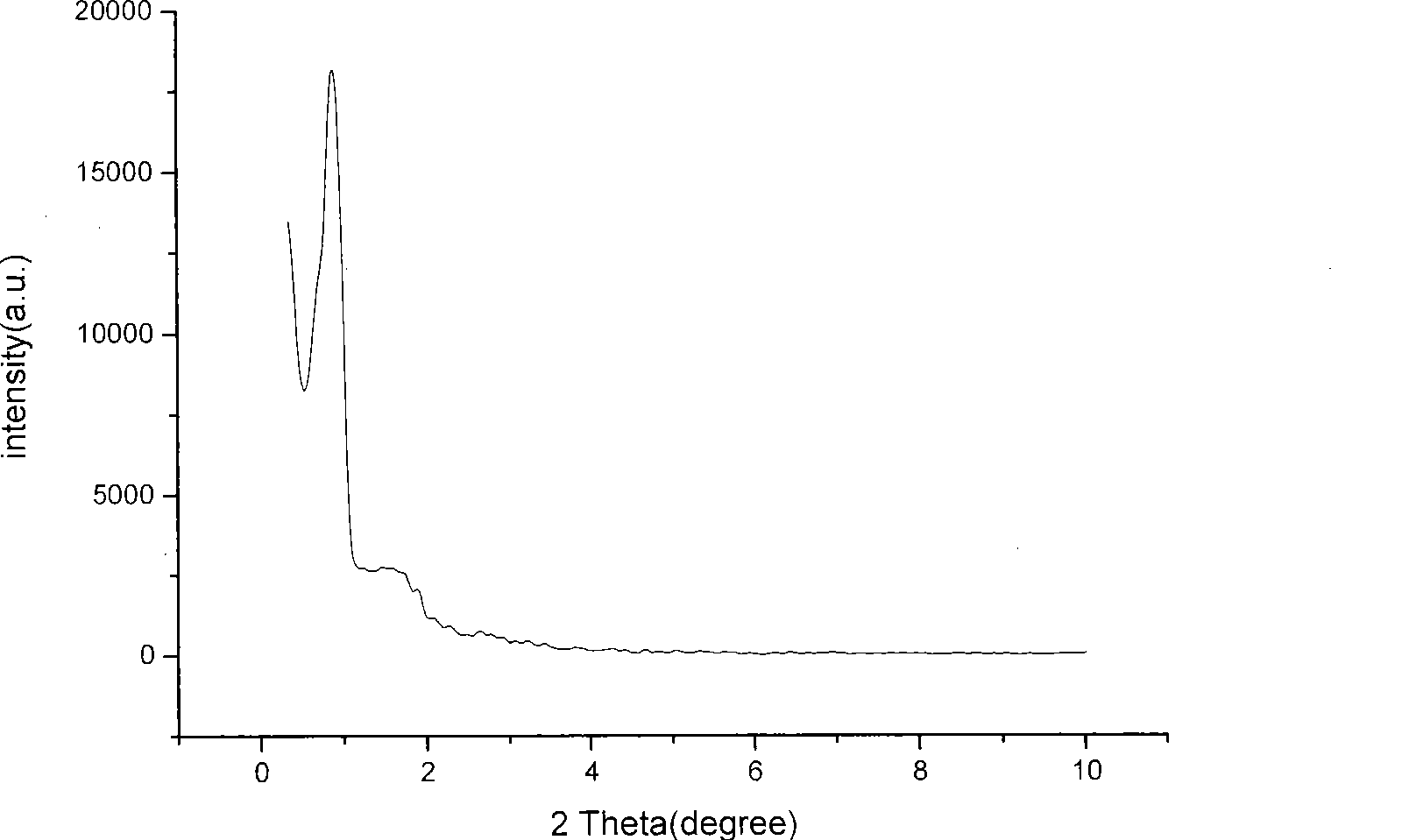

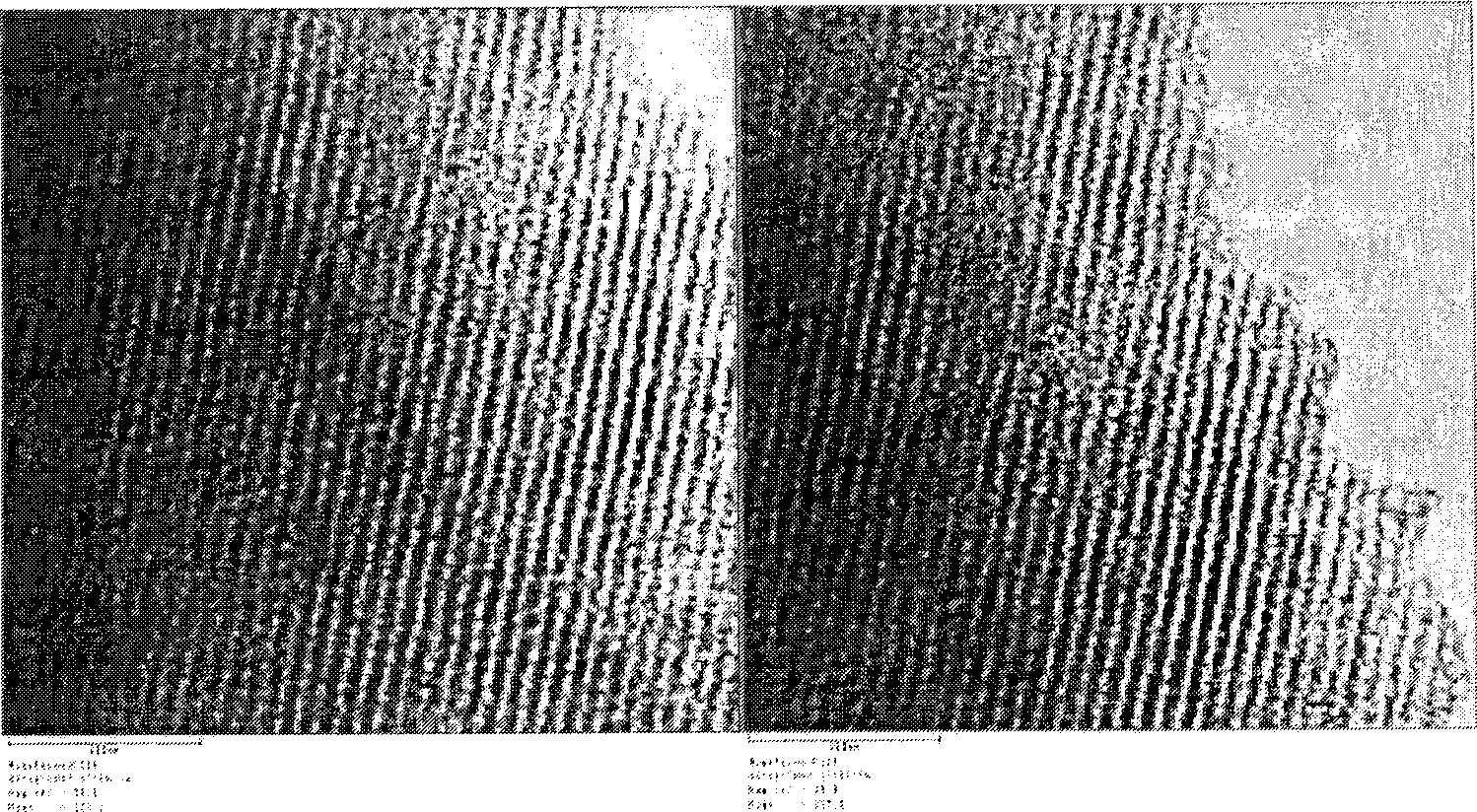

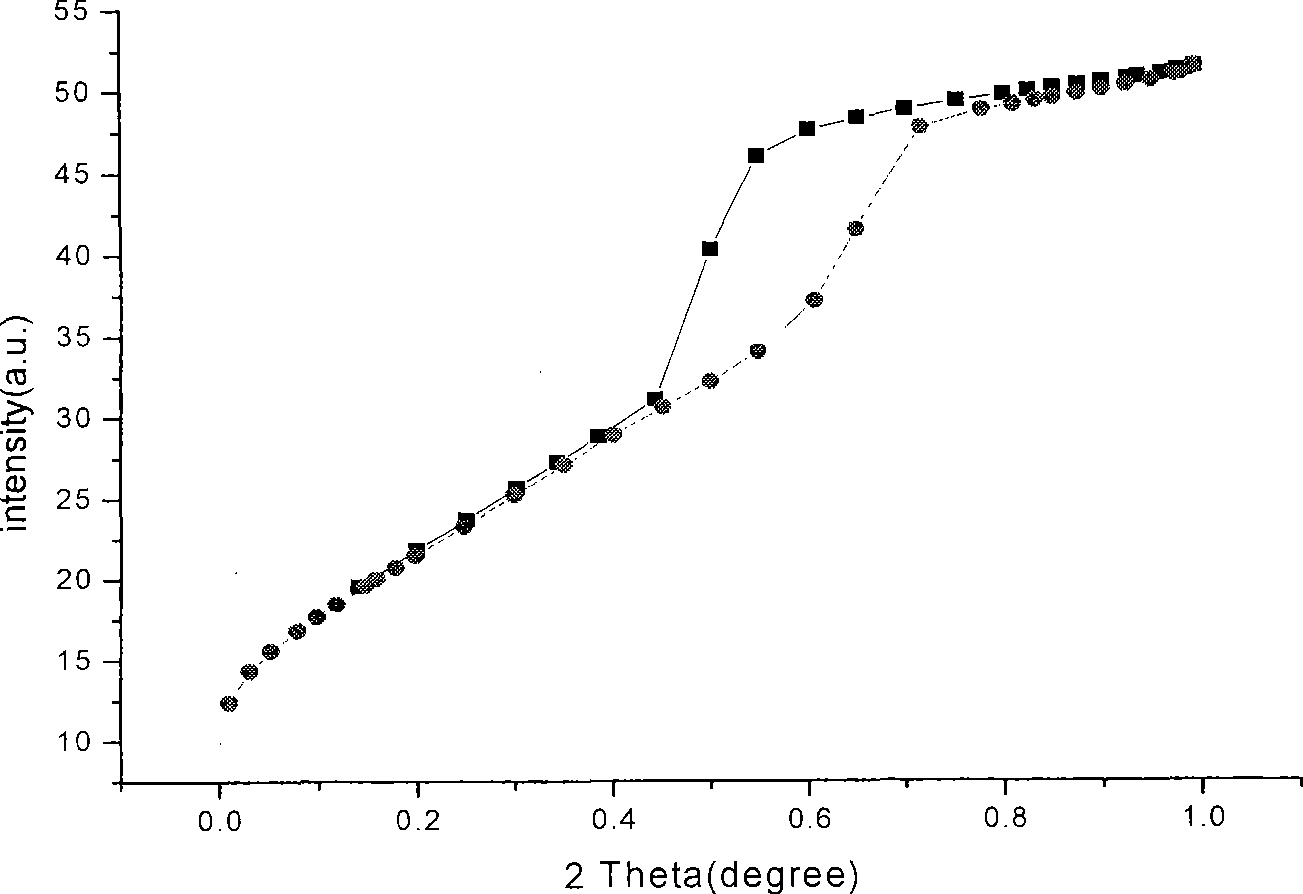

[0015] In the early stage of the experiment, phenol and formaldehyde were used to polymerize under alkaline conditions to obtain a low molecular weight (less than 500) resol resin precursor, which was formulated into a phenolic resin ethanol solution with a mass fraction of 20% for later use. Dissolve 1.0 g of template agent F127 in 10.0 g of absolute ethanol, add 1.0 g of 0.2 mol / L HCl solution dropwise, and stir at 40°C for 1 h to form a transparent solution. Slowly add 2.08g tetraethyl orthosilicate and 2.5g ethanol solution (20%) of phenolic resin dropwise, stir for 2h to make it evenly mixed. The mixture was transferred to a flat-bottomed Petri dish, and the solvent was evaporated at room temperature (25° C.) for 5-8 h to form a uniform film. Transfer to a microwave oven for microwave polymerization with a microwave power of 200W for 30 minutes. Carbonization was carried out in an atmosphere tube furnace with nitrogen gas flow. Incubate at 350°C for 5 hours, 500°C and 6...

specific Embodiment 3

[0017] In the early stage of the experiment, phenol and formaldehyde were used to polymerize under alkaline conditions to obtain a low molecular weight (less than 500) resol resin precursor, which was formulated into a phenolic resin ethanol solution with a mass fraction of 20% for later use. Dissolve 1.0 g of template agent F127 in 10.0 g of absolute ethanol, add 1.0 g of 0.2 mol / L HCl solution dropwise, and stir at 40°C for 1 h to form a transparent solution. Slowly add 2.08g tetraethyl orthosilicate and 2.5g ethanol solution (20%) of phenolic resin dropwise, stir for 2h to make it evenly mixed. The mixture was transferred to a flat-bottomed Petri dish, and the solvent was evaporated at room temperature (25° C.) for 5-8 h to form a uniform film. Transfer to a microwave oven for microwave polymerization with a microwave power of 600W for 60 minutes. Carbonization was carried out in an atmosphere tube furnace with nitrogen gas flow. Incubate at 350°C for 5 hours, at 500°C an...

specific Embodiment 4

[0019]Specific embodiment four (comparative examples):

[0020] (1) In the early stage of the experiment, phenol and formaldehyde were used to polymerize under alkaline conditions to obtain a low molecular weight (less than 500) resole resin precursor, and a phenolic resin ethanol solution with a mass fraction of 20% was prepared for future use. Dissolve 1.0 g of template agent F127 in 10.0 g of absolute ethanol, add 1.0 g of 0.2 mol / L HCl solution dropwise, and stir at 40°C for 1 h to form a transparent solution. Slowly add 2.08g tetraethyl orthosilicate and 2.5g ethanol solution (20%) of phenolic resin dropwise, stir for 2h to make it evenly mixed. The mixture was transferred to a flat-bottomed Petri dish, and the solvent was evaporated at room temperature (25° C.) for 5-8 h to form a uniform film. Put it into a vacuum oven for thermal polymerization at 100°C for 24 hours, and carbonize it in an atmosphere tube furnace with nitrogen flow. Insulate at 350°C for 5 hours, at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com