Biomimetic self-healing phase-change heat-absorption A1 microcapsule/ceramic-base composite heat-proof material and preparation method thereof

A technology of ceramic matrix composite and heat-proof material, which is applied in the field of biomimetic self-healing phase change endothermic Al microcapsule/ceramic matrix composite heat-proof material and preparation to achieve the effect of improving low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

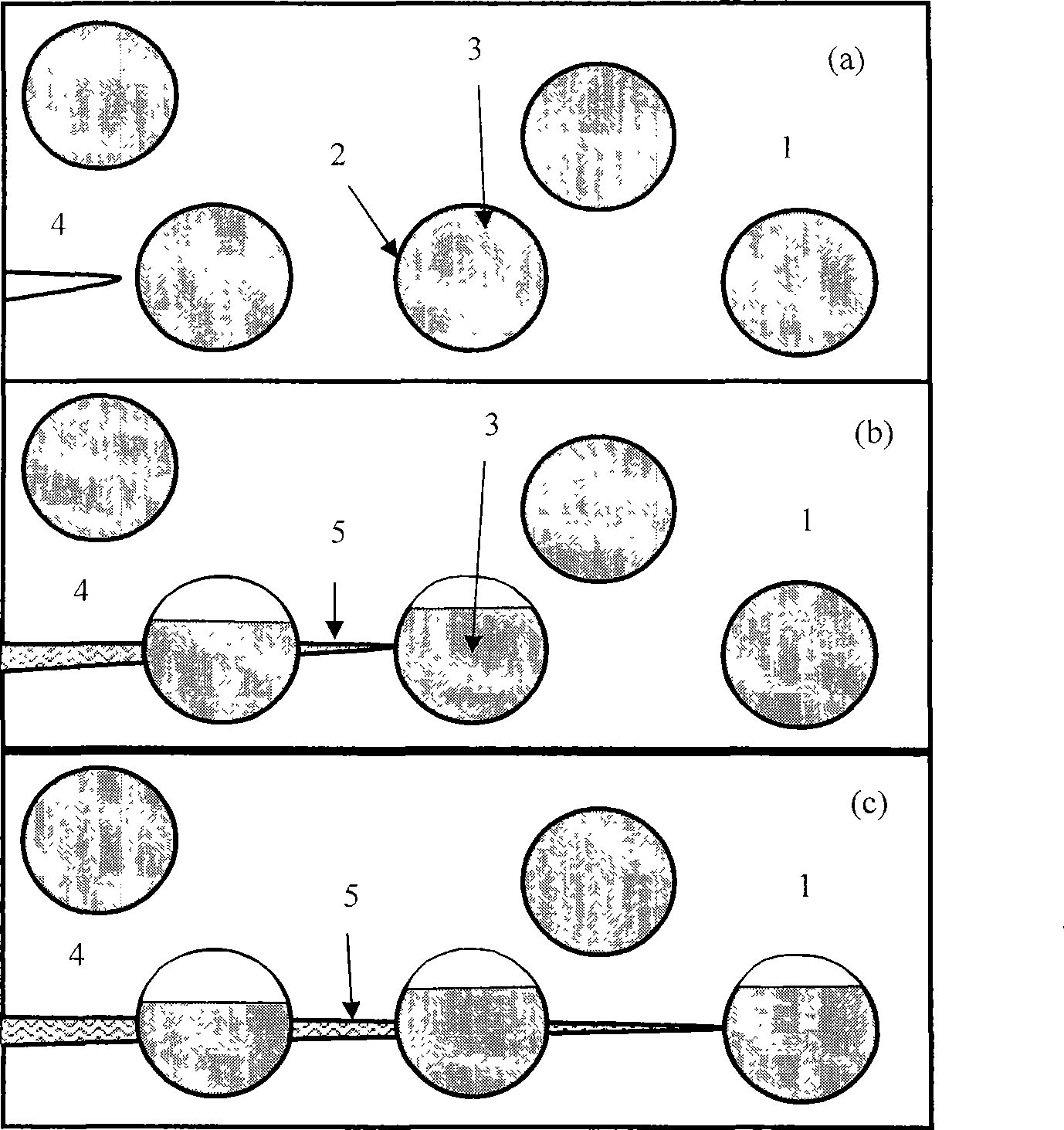

[0028] Example 1: Pre-oxidation method

[0029] Commercial 6101 aluminum alloy powder is selected, its main components are silicon 0.3-0.7%, magnesium 0.35-0.8% and the maximum content of iron 0.5%, there are also 0.1% or less than 0.1% of elements including copper, zinc, boron , manganese and chromium.

[0030] Sieve the aluminum powder to make sure that the particle size of the aluminum powder is between 300-350 mesh, then wash the aluminum powder with alcohol, filter it with suction, dry it, and pre-oxidize it at 900°C for 1 hour to form a ceramic thin shell coating Al microcapsules.

[0031]The alumina matrix powder, basic magnesium carbonate sintering aid, and Al microcapsules coated with ceramic thin shells are prepared as raw materials according to the volume percentage ratio of 90%, 4%, and 6%, and the alumina balls are used for mixed ball milling, and the ball milling time is 2 hours After ball milling, the mixed powder material was put into a mold for compression m...

example 2

[0032] Example 2: Coating method

[0033] 1) Clean the aluminum powder, pass the aluminum powder through a 400-425 mesh sieve, then wash the aluminum powder with alcohol / acetone, suction filter, dry, add distilled water to make a dilute suspension with a mass fraction of 10%, and perform ultrasonic dispersion.

[0034] 2) After heating to the predetermined temperature, slowly add 20g / L aluminum chloride solution into the suspension within the specified time, and add ammonia water dropwise at the same time to keep the pH value of the suspension stable. After adding the aluminum chloride solution, keep the temperature at 25°C for 2 hours. Then filter, wash, dry at 110°C for 12 hours, and then heat-treat at 500°C for 3 hours to prepare alumina-coated Al microcapsule powder with an average diameter of about 50 microns. The average thickness of the aluminum oxide shell is about 1.1 microns.

[0035] 3) Ingredients: mixing the prepared alumina-coated Al microcapsule powder with al...

example 3

[0038] Example 3: Coating method

[0039] 1) Clean the aluminum powder, pass the aluminum powder through a 400-425 mesh sieve, then wash the aluminum powder with alcohol / acetone, suction filter, dry, add ethanol to make an alcohol suspension with a mass fraction of 15%, and carry out ultrasonic dispersion .

[0040] 2) According to the hydrolysis of ethyl orthosilicate, the best conditions can be obtained: TEOS: C2H5OH: H2O: NH3 = 1:10:4:1 (molar ratio), prepare silica sol, and add acetamide as an additive during the reaction process , the reaction temperature is 20°C, and the reaction time is 5h.

[0041] 3) The suspension was filtered, washed, dried at 110°C for 12 hours, and then heat-treated at 500°C for 3 hours to obtain alumina-coated Al microcapsule powder.

[0042] 3) Ingredients: The prepared Al microcapsule powder is mixed with the silicon oxide ceramic matrix powder raw material, forming aids, and sintering aids at a volume ratio of 30:60:4:6.

[0043] 4) Briquet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com