Method for producing curing agent having acidic substituent and unsaturated maleimide group, thermosetting resin composition, prepreg, and laminate

A maleimide-based, resin composition technology, applied in chemical instruments and methods, synthetic resin layered products, organic chemistry, etc., can solve the problem of insufficient heat resistance and copper cladding heat resistance, low solubility and processing. Solubility, low thermal decomposition temperature of the cured product, etc., to achieve the effects of good solubility, excellent performance, low dielectric loss tangent and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0096] The present invention is illustrated in more detail by the following examples, but these examples do not limit the invention.

[0097] The performances of the copper clad laminates obtained in the following examples were measured and evaluated by the following methods.

[0098] (1) Evaluation of copper foil adhesion (copper foil peel strength)

[0099] By immersing the copper-clad laminate in a copper etchant, leaving a strip-shaped portion with a width of 1 cm, an evaluation substrate with the copper foil removed was prepared, and the thickness of the strip-shaped portion was measured by using an electronic universal testing machine [Shimadzu Corporation AG-100C]. Peel strength was evaluated.

[0100] (2) Determination of glass transition temperature (Tg)

[0101] By immersing the copper-clad laminate in a copper etching solution, a 5 mm square evaluation substrate with the copper foil removed was prepared, and measured from the thermal expansion characteristics of t...

manufacture example 1

[0112] Production Example 1: Production of Curing Agent (A-1)

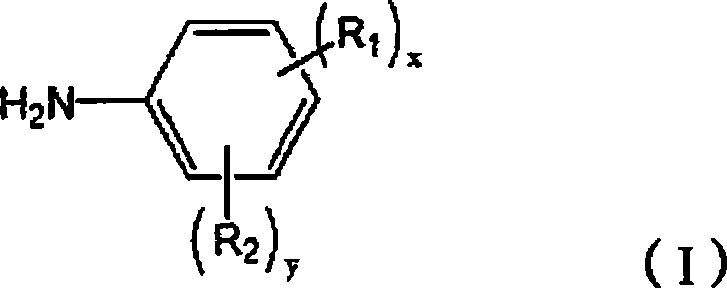

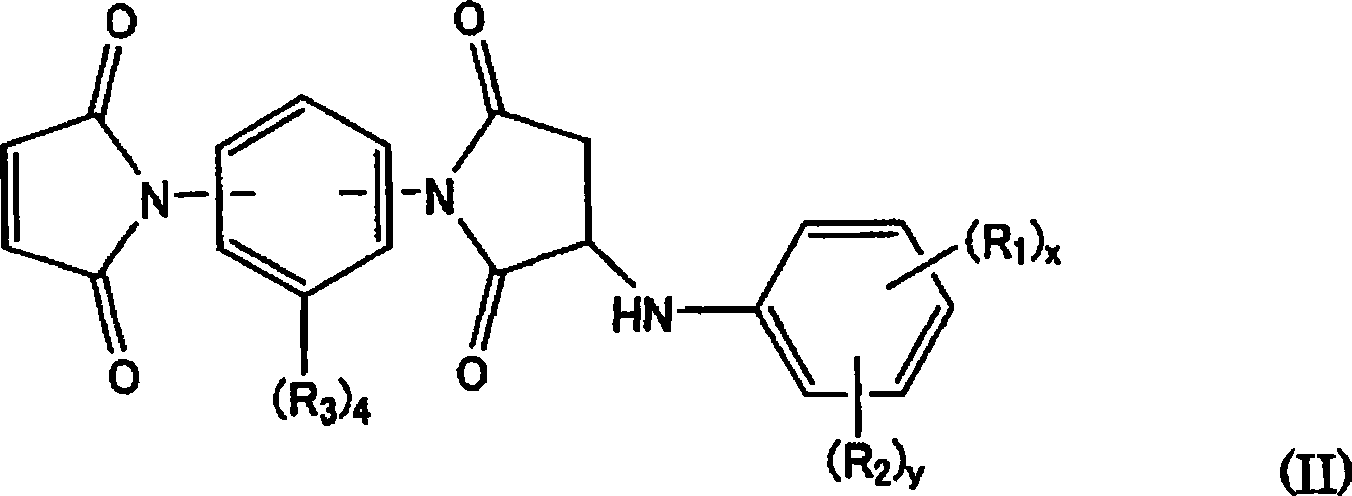

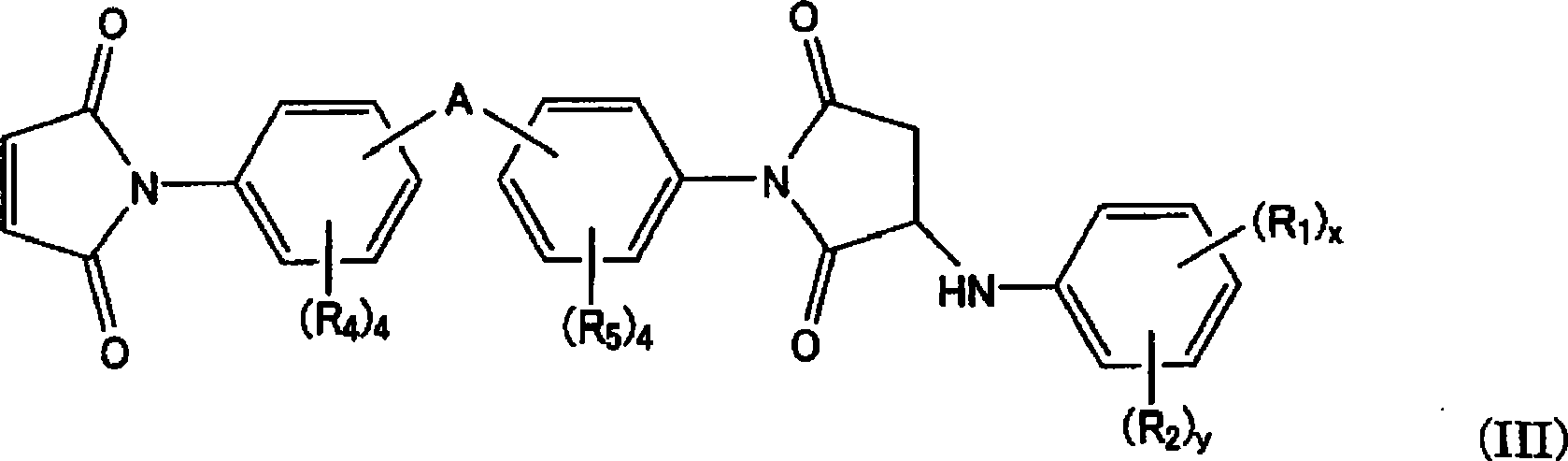

[0113] Add 358.00 g of bis(4-maleimide benzene) methane, m-amino 54.50 g of phenol and 412.50 g of an organic solvent (propylene glycol monomethyl ether) were reacted for 5 hours while refluxing to obtain a curing agent (A-1) containing an organic solvent.

manufacture example 2

[0114] Production Example 2: Production of Curing Agent (A-2)

[0115] Add bis(4-maleimidobenzene)methane 358.00g, p-amino 54.50 g of phenol and 412.50 g of an organic solvent (propylene glycol monomethyl ether) were reacted for 5 hours while refluxing to obtain a curing agent (A-2) containing an organic solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com