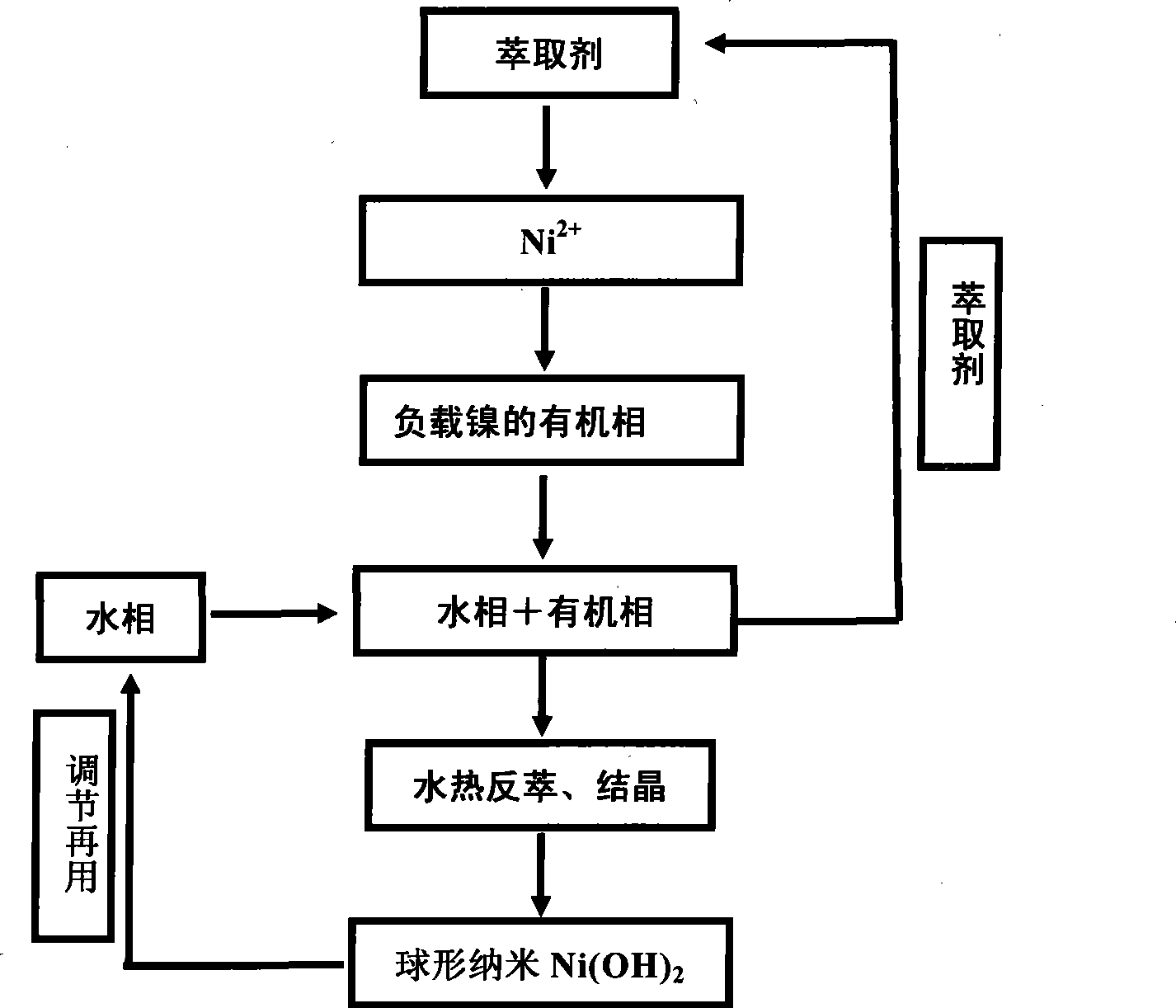

Preparation of spherical Ni(OH)2 nano powder

A nano-powder and spherical technology, which is applied in the field of preparation of spherical Ni2 nano-powder, can solve the problems of difficult control of product particle size, difficult industrial production, irregular shape, etc. The effect of product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A spherical Ni(OH) 2 The preparation method of nanopowder is made up of following steps:

[0027] (1) Preparation of loaded nickel organic phase:

[0028] Under magnetic stirring, add naphthenic acid with an average molecular weight between 200 and 350, isooctyl alcohol and 1.0 mol·L -1 NiSO 4 aqueous solution, add 1.0mol·L -1 Adjust the pH value with ammonia water to 7, continue to stir for 0.5 hours, pour the mixed solution into the separating funnel, separate the liquid after standing still for 5 minutes, wash the organic phase with distilled water and then separate the liquid twice, collect the organic phase, which is the nickel-loaded organic phase ;

[0029] (2) Preparation of water phase:

[0030] Add 1.0mol L in distilled water -1 The hydrochloric acid adjustment pH value is 6, obtains aqueous phase;

[0031] (3) Hydrothermal stripping and crystal formation:

[0032] The aqueous phase and the nickel-loaded organic phase were introduced into the autoclave...

Embodiment 2

[0038] A spherical Ni(OH) 2 The preparation method of nanopowder is made up of following steps:

[0039] (1) Preparation of loaded nickel organic phase:

[0040] With embodiment 1;

[0041] (2) Preparation of water phase:

[0042] Use distilled water directly;

[0043] (3) Hydrothermal stripping and crystal formation:

[0044] With embodiment 1;

[0045] (4) Product handling:

[0046] With embodiment 1;

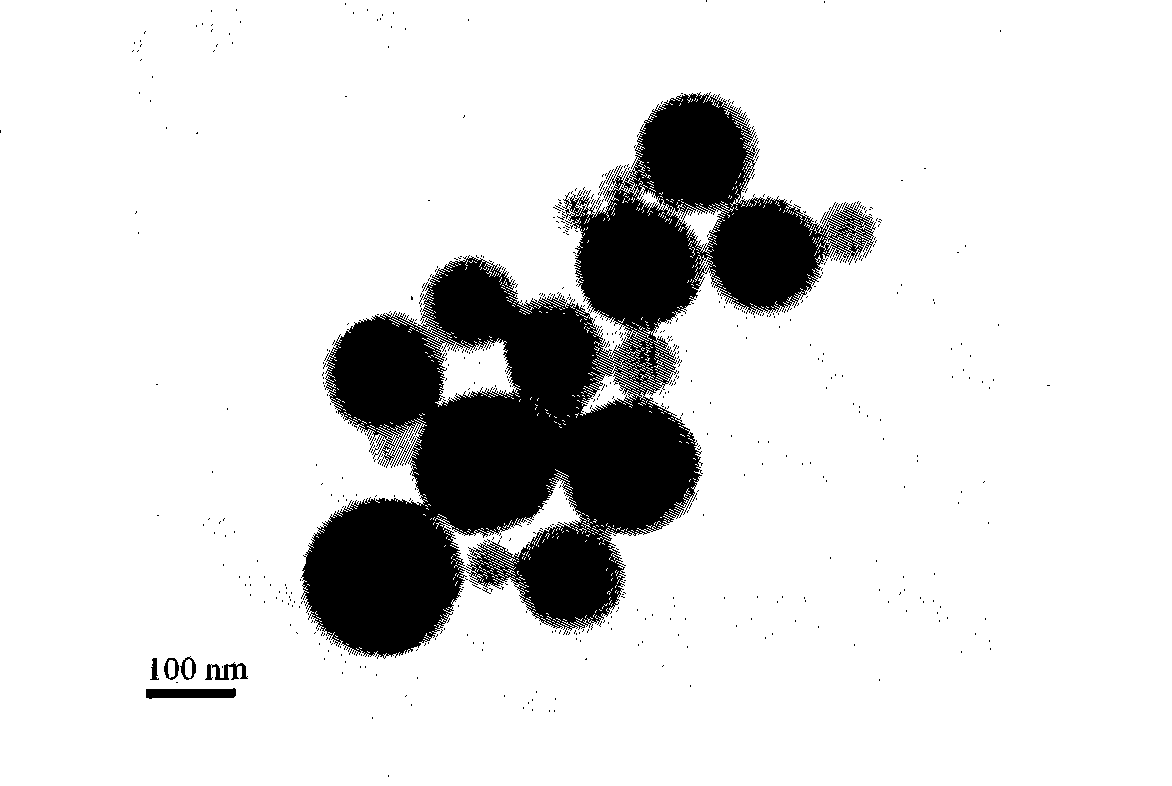

[0047] (5) Product characterization

[0048] Spherical Ni(OH) 2 Nano powder products are measured by 18KW target X-ray diffractometer (Japan Rigaku Co., Ltd.) and the results show that the product has Ni(OH) 2 diffraction features. Observe the morphology and particle size of the product under a JEM-100C*II transmission electron microscope (Japan Electronics JEOL). image 3 , the product is spherical.

Embodiment 3

[0050] A spherical Ni(OH) 2 The preparation method of nanopowder is made up of following steps:

[0051] (1) Preparation of loaded nickel organic phase:

[0052] With embodiment 1;

[0053] (2) Preparation of water phase:

[0054] Add 1.0mol L in distilled water -1 The ammonia water adjusts the pH value to be 8;

[0055] (3) Hydrothermal stripping and crystal formation:

[0056] With embodiment 1;

[0057] (4) Product handling:

[0058] With embodiment 1;

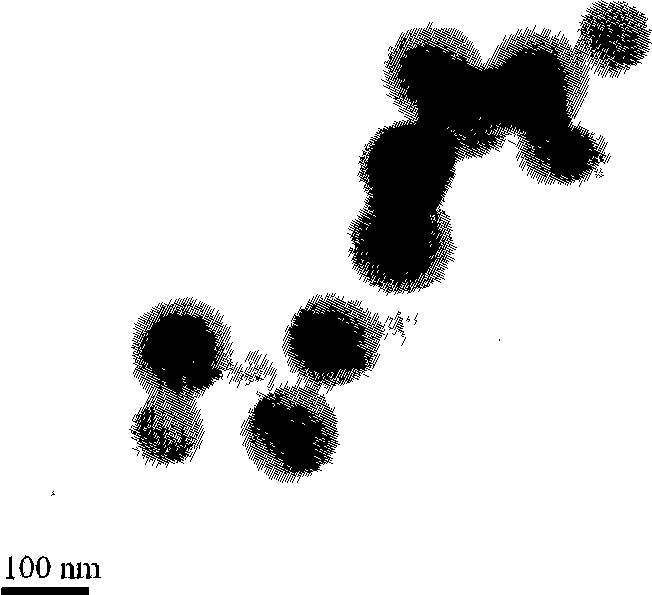

[0059] (5) Product characterization

[0060] Spherical Ni(OH) 2 Nano powder products are measured by 18KW target X-ray diffractometer (Japan Rigaku Co., Ltd.) and the results show that the product has Ni(OH) 2 diffraction features. Observe the morphology and particle size of the product under a JEM-100C*II transmission electron microscope (Japan Electronics JEOL). Figure 4 , the product is spherical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com