Biological treatment method and apparatus for organic containing water

A technology of biological treatment and treatment device, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problem of RO membrane desalination performance decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

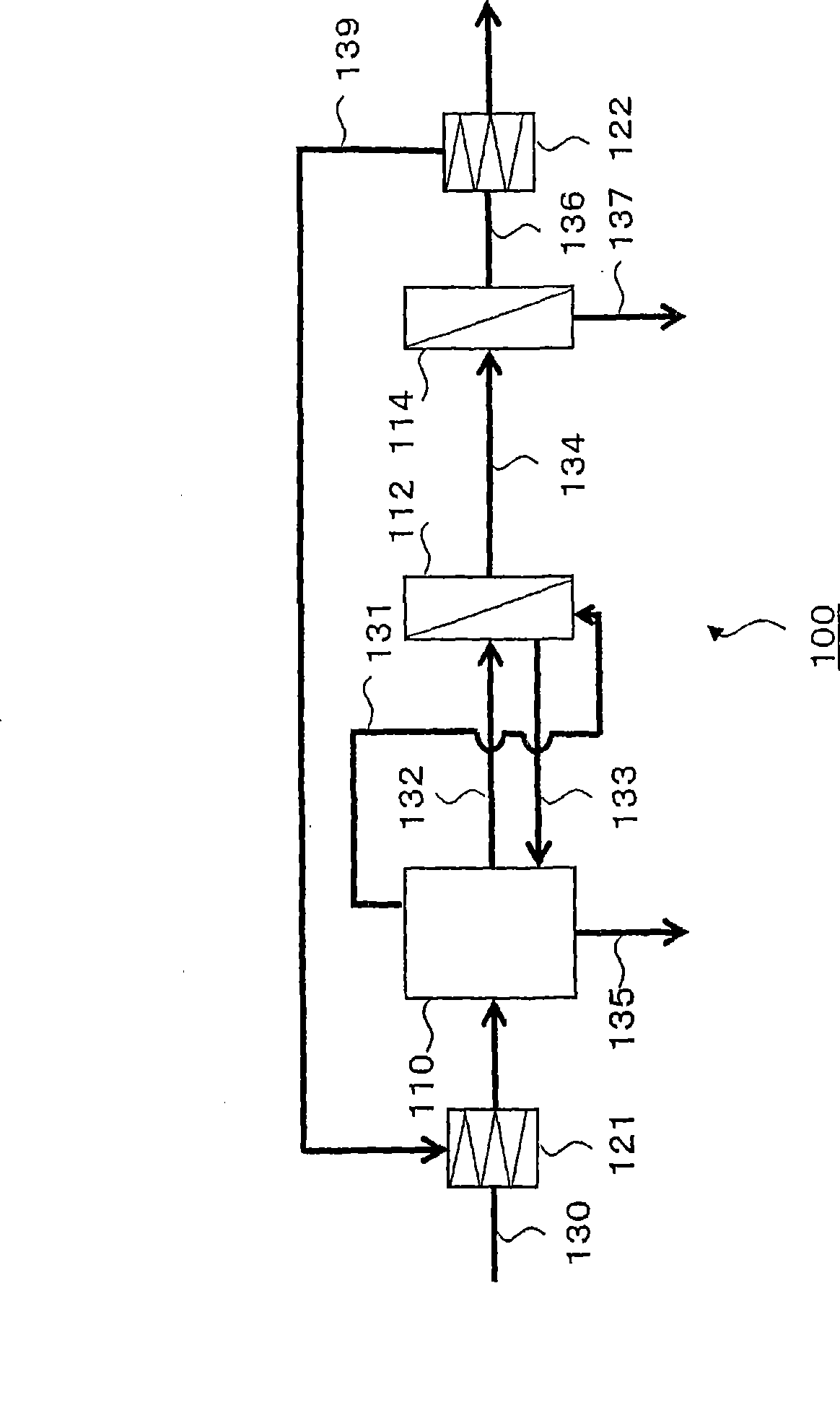

[0061] figure 1 It is a schematic diagram of the biological treatment apparatus (hereinafter simply referred to as "treatment apparatus") 100 of organic matter-containing water used in the present invention. The treatment device 100 includes an anaerobic biological treatment tank (hereinafter referred to as “reactor”) 110 , a membrane separation device 112 , and a reverse osmosis membrane device 114 . A raw water pipe 130 is connected to the inlet of the reactor 110 . The reactor 110 is connected to the membrane separation device 112 through the treatment liquid pipe 132 , and the membrane separation device 112 is connected to the reverse osmosis membrane device 114 through the separation water pipe 134 . A permeated water pipe 136 is connected to the outlet of the reverse osmosis membrane device 114 .

[0062] The first heat exchanger 121 is provided in the pipeline of the raw water pipe 130 , and the second heat exchanger 122 is provided in the pipeline of the permeated wa...

Embodiment 1

[0075] As Example 1, the simulated figure 1 Experiments were performed on the experimental apparatus obtained from the processing apparatus 100 shown. The reactor 110 of the experimental device has an effective volume of 1m 3 , Hydraulic retention time 0.5 day operation. In the reactor 110, the granular sludge taken out from the anaerobic reactor for treating methanol is domesticated with a liquid to be treated described later, and is kept as a planktonic sludge. The concentration of the planktonic sludge in the reactor 110 is 4000 mg / L, 40% of the existing amount (compared with wet weight) is the methanogenic flora, and 60% is the self-digested residue of the methanogenic flora.

[0076] As water to be treated, organic matter-containing water having a total organic matter carbon concentration of 750 mg / L, a nitrogen concentration of 218 mg / L, and a phosphorus concentration of 1.0 mg-P / L was used. The composition of the total organic matter is tetramethylammonium hydroxide ...

Embodiment 2

[0080] In Example 2, instead of the UF membrane used in Example 1, an MF membrane with a pore diameter of 400 nm was used. Other than that, when the experiment was performed under the same conditions as in Example 1, the TOC concentration of the separated water from the membrane separation device equipped with the MF membrane was the same as in Example 1, and was in the range of 3 to 4 mg / L. In addition, the flow rate of the membrane separation device 112 was maintained at 1.0 m / day, and the flow rate when the separated water was treated with the reverse osmosis membrane device 114 in the same manner as in Example 1 was maintained at the original 90 m even after 20 hours from the beginning of water flow. %. On the other hand, the water passage resistance was a maximum of 40 kPa, which was higher than that of Example 1. In the sludge in the reactor 110, since the average diameter of the methanogenic bacteria group is 800nm, it is presumed that when the MF membrane is used, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com