Anaerobic cellulose-degrading methane producing composite bacterium

A technology for degrading cellulose and producing methane, applied to bacteria, microorganisms, waste fuels, etc., can solve the problems of single enzyme production, difficulty in degrading lignocellulose, and unrecoverable culture medium, so as to increase methane content, speed up fermentation start, The effect of fast and efficient hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An anaerobic cellulose-degrading methanogenic complex bacteria, composed of the following 13 strains, the cell number content of the 13 strains in the complex bacteria: Cytophaga fermentans accounted for 10%, Clostridium papyrosolvens accounted for 25%, Desulfovibrio vulgaris accounted for 1%, Butyrivibriofibrisolvens accounted for 1% 5%, Acetobacterium woodii 5%, Cellulomonas flavigena 1%, Clostridium termitidis 1%, Clostridium cellobioparum 2.5%, Syntrophomonas Wolfei 5%, Methanosarcina barkeri 19%, Methanobrevibacter arboriphilicus 15%, Methanosphaera stadtmaniae 8% vannielii accounted for 2.5%.

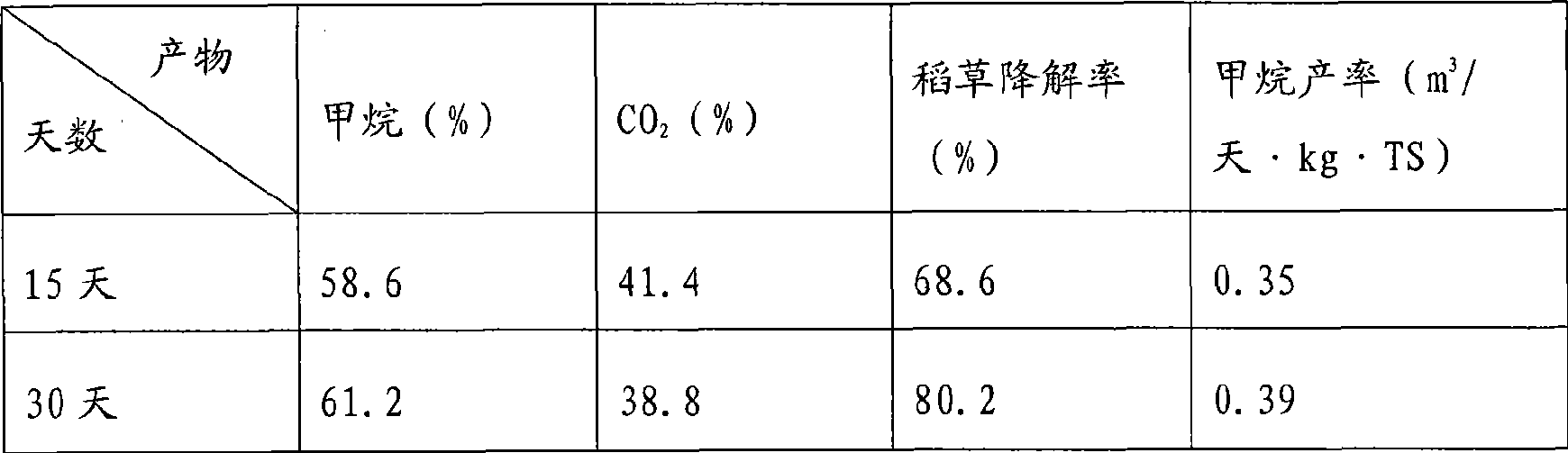

[0038] The composite bacteria with the above composition are inserted into the cellulose liquid culture medium with rice straw as the carbon source, sealed and cultured statically. See the table below for the straw degradation effect and the gas concentration results produced after cultivating for 15 days and 30 days:

[0039]

Embodiment 2

[0041] An anaerobic cellulose-degrading methanogenic complex bacteria, composed of the following 13 strains, the cell number content of the 13 strains in the complex bacteria: Cytophaga fermentans accounted for 7.5%, Clostridium papyrosolvens accounted for 35%, Desulfovibrio vulgaris accounted for 3%, Butyrivibriofibrisolvens accounted for 3% 4%, Acetobacterium woodii 5%, Cellulomonas flavigena 5%, Clostridium termitidis 3%, Clostridium cellobioparum 5%, Syntrophomonas Wolfei 5%, Methanosarcina barkeri 10%, Methanobrevibacter arboriphilicus 10%, Methanosphaera stadtmaniae 5%, vannielii accounted for 2.5%.

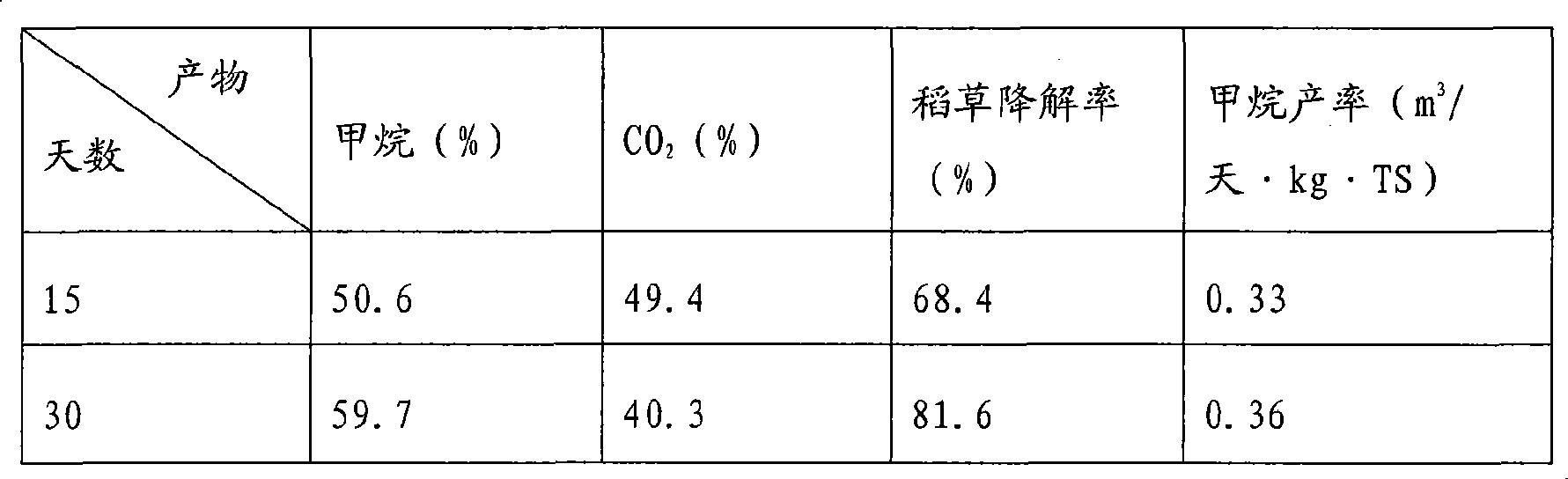

[0042] The composite bacteria with the above composition are inserted into the cellulose liquid culture medium with rice straw as the carbon source, sealed and cultured statically. See the table below for the straw degradation effect and the gas concentration results produced after cultivating for 15 days and 30 days:

[0043]

Embodiment 3

[0045] An anaerobic cellulose-degrading methanogenic complex bacteria, composed of the following 13 strains, the cell number content of the 13 strains in the complex bacteria: Cytophaga fermentans accounted for 6%, Clostridium papyrosolvens accounted for 25%, Desulfovibrio vulgaris accounted for 2%, Butyrivibriofibrisolvens 4%, Acetobacterium woodii 10%, Cellulomonas flavigena 5%, Clostridium termitidis 3%, Clostridium cellobioparum 3%, Syntrophomonas Wolfei 10%, Methanosarcina barkeri 13%, Methanobrevibacter arboriphilicus 10%, Methanosphaera stadtvanethanielcus 4% 5%.

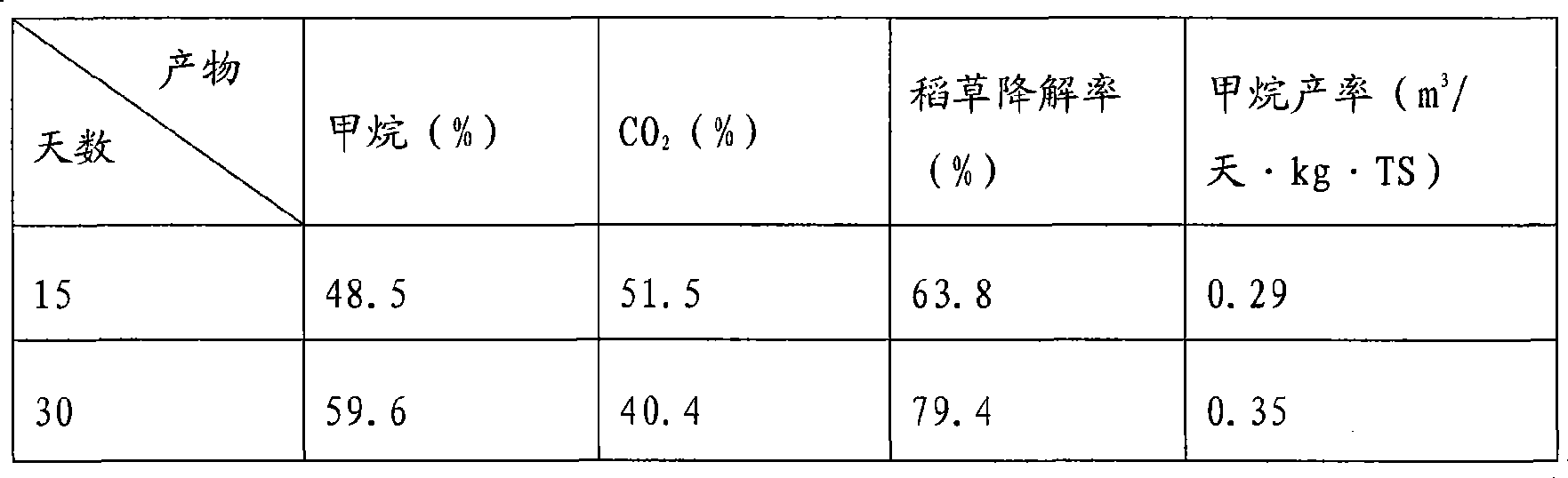

[0046] The composite bacteria with the above composition are inserted into the cellulose liquid culture medium with rice straw as the carbon source, sealed and cultured statically. See the table below for the straw degradation effect and the gas concentration results produced after cultivating for 15 days and 30 days:

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com