Phase-change heat-exchange type secondary steam heat recovery utilization method, apparatus and use thereof

A technology of secondary steam and phase change heat, applied in separation methods, indirect heat exchangers, heat exchanger types, etc., can solve the problems of low utilization rate of heat energy, unavailability, and small application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Phase-change heat recovery and utilization device for secondary steam heat energy:

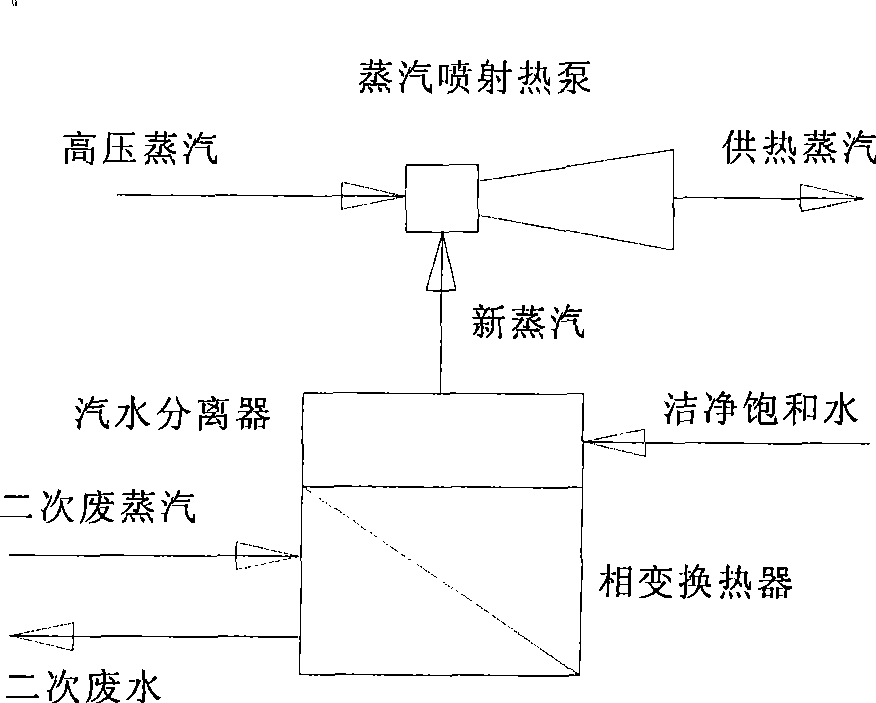

[0065] The phase-change heat recovery and utilization device for secondary steam heat energy is composed of a phase-change heat exchanger, a steam-water separator, a negative pressure mechanical compression heat pump or a steam injection heat pump, or a combination of them connected by pipelines (see Figure 3-Figure 6 );

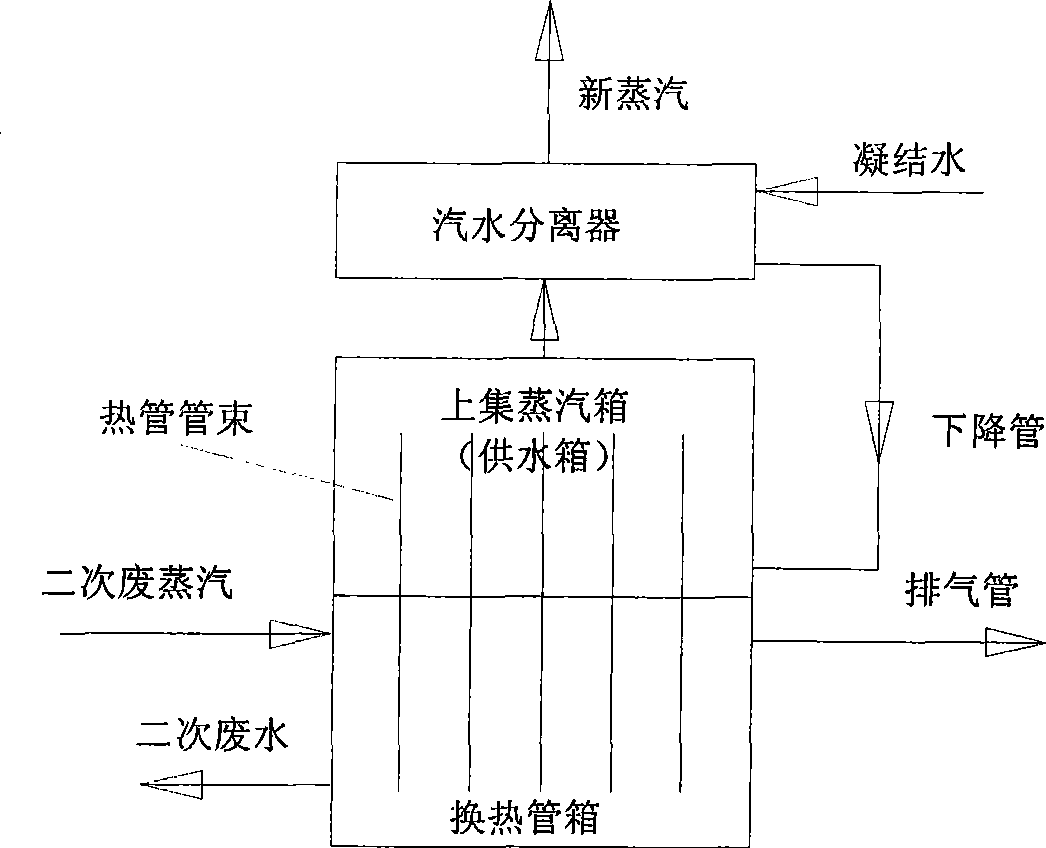

[0066] 1) Phase-change heat exchangers: divided into conventional (non-heat pipe) phase-change heat exchangers and heat pipe phase-change heat exchangers

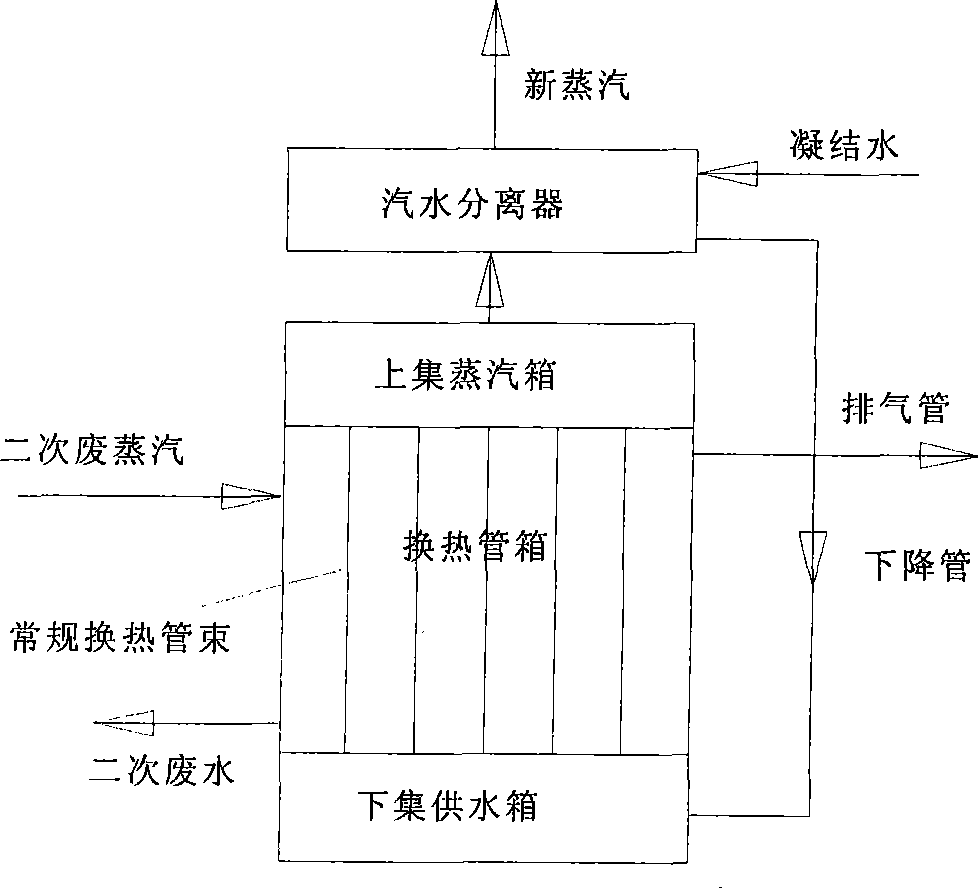

[0067] a. Schematic diagram of conventional phase change heat exchanger figure 1 As shown, it is composed of heat exchange tube box, lower water supply tank, upper steam box, secondary steam condensate and non-condensable gas exhaust pipe; its main function is to remove the vapor phase (dirty, corroded) entering the heat exchange tube box The secondary steam condenses into liquid-phase saturated water...

Embodiment 2

[0073] Example 2: Phase-change heat recovery and utilization method of secondary steam heat energy

[0074] 1) The steps of the phase-change heat recovery and utilization method of secondary steam heat energy:

[0075] a. First, inject evaporation water into the water supply tank under the phase change heat exchanger. If the saturated condensed water of the dryer, distiller or concentrator is used as the evaporation water, the water can be injected into the steam-water separator and descend through the steam-water separator. Connect the pipe to inject evaporation water into the lower header of the phase-change heat evaporator;

[0076] b. While injecting evaporation water into the phase-change heat exchanger, start the heat pump to draw negative pressure on the steam-water separator, phase-change heat evaporator, and each evaporation connecting pipe and box; the negative pressure value is set at a temperature lower than the boiling point of the evaporation water The saturatio...

Embodiment 3

[0087] Example 3: Application of phase-change heat recovery and utilization device and method for secondary steam heat energy in drying equipment

[0088] The principle of phase conversion heat recovery and utilization device for secondary steam heat energy applied to drying is as follows: Figure 7 Shown: The dotted line box in the figure is a phase-change heat recovery and utilization device for secondary steam heat energy.

[0089] The primary heating steam indirectly heats the wet material, the primary heating steam releases the heat of evaporation, conducts it to the material and condenses, and discharges it from the steam trap to the phase-change heat type secondary steam heat recovery device; the wet material absorbs the evaporation heat, and the temperature rises to When the water reaches the boiling point, it evaporates into secondary steam and the material enters the phase-change heat recovery and utilization device of secondary steam heat energy, and the wet materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com