Quantitative measuring method for trace amount of foreign gas in chlorine

A technology for quantitative determination and trace impurities, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of sample contamination data, large relative error, and inability to measure, so as to achieve good separation effect, reduce analysis error, and strict sampling process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

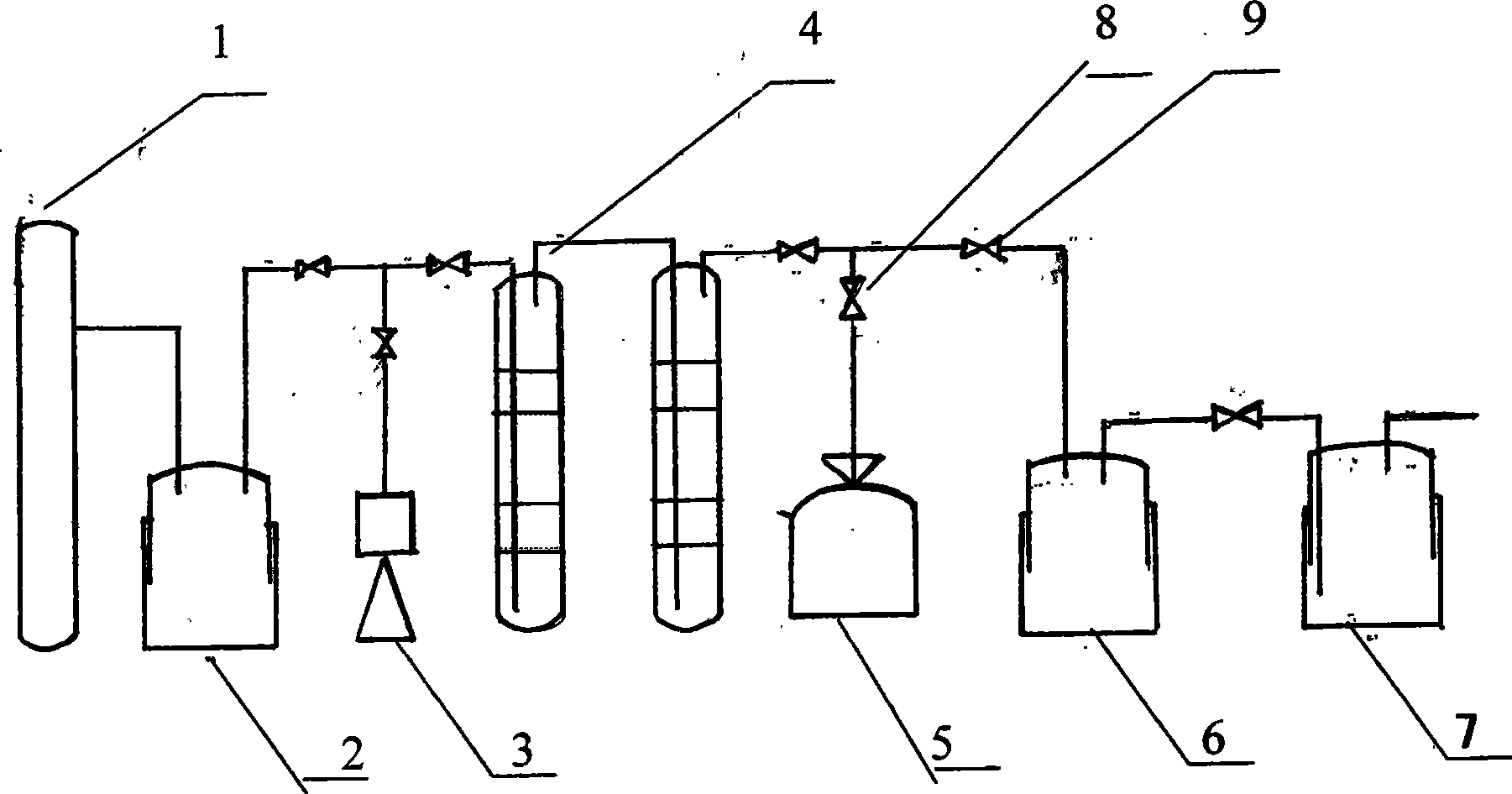

[0020] The present invention first sets up sampling device when implementing, and sampling device is as figure 1 As shown, it is a branch pipe connected from the chlorine gas pipe 1, and the branch pipe is successively connected with a gas-liquid separator 2, a vacuum pump 3 and a two-stage absorption bottle 4 filled with concentrated sulfuric acid. The outlet of the two-stage absorption bottle 4 is divided into two paths , one road is connected to the sampling bladder 5 through the air inlet valve 8, and the other road is connected to the residual gas buffer bottle 6 and the absorption bottle 7 that sodium hydroxide is housed through the air outlet valve 9.

[0021] When sampling, first replace the original gas in the sampling device with argon, then close the sampling bladder inlet valve 8 and outlet valve 9; open the branch pipeline and vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com