Preparation of conductive polymer / carbon nano-tube composite mesoporous nano-tube

A carbon nanotube composite and conductive polymer technology, which is applied in the field of preparation of conductive polymer/carbon nanotube composite mesoporous nanotubes, can solve problems that do not involve conductive polymer/carbon nanotube composite mesoporous nanotubes, Conducting polymer/carbon nanotube composite mesoporous nanotube synthesis and other issues, to achieve the effect of easy preparation, simple system and simple purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The typical steps for the synthesis of conductive polymer / carbon nanotube composite mesoporous nanotubes are as follows:

[0026] 1. Mix carbon nanotubes (including single-wall, double-arm and multi-wall carbon nanotubes) with potassium permanganate aqueous solution (0.01M~1M), react at 50~100℃ for 1~20 hours, precipitate and disperse and pass Filtration method is used for separation to obtain a composite nanostructure of carbon nanotubes coated with manganese dioxide. The potassium permanganate aqueous solution is more than five times the mass of the carbon nanotubes. In this embodiment, the potassium permanganate aqueous solution is 25 times the mass of the carbon nanotubes, and reacted at 70° C. for 6 hours.

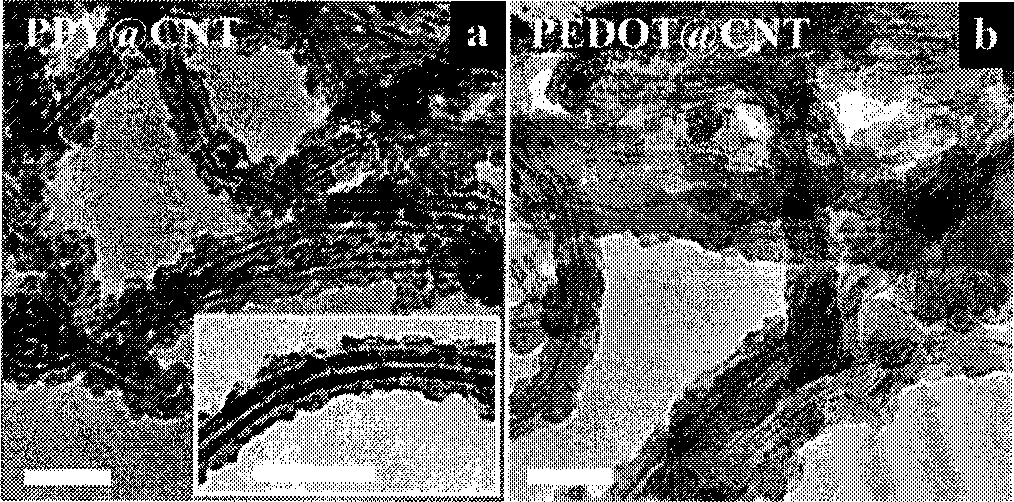

[0027] 2. Preparation of conductive polymer / carbon nanotube composite mesoporous nanotubes, MnO 2 The @CNTs raw material is dispersed in a solvent (solvent includes water and ionic liquid, etc.), and the conductive polymer monomer is dissolved with a solvent o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com