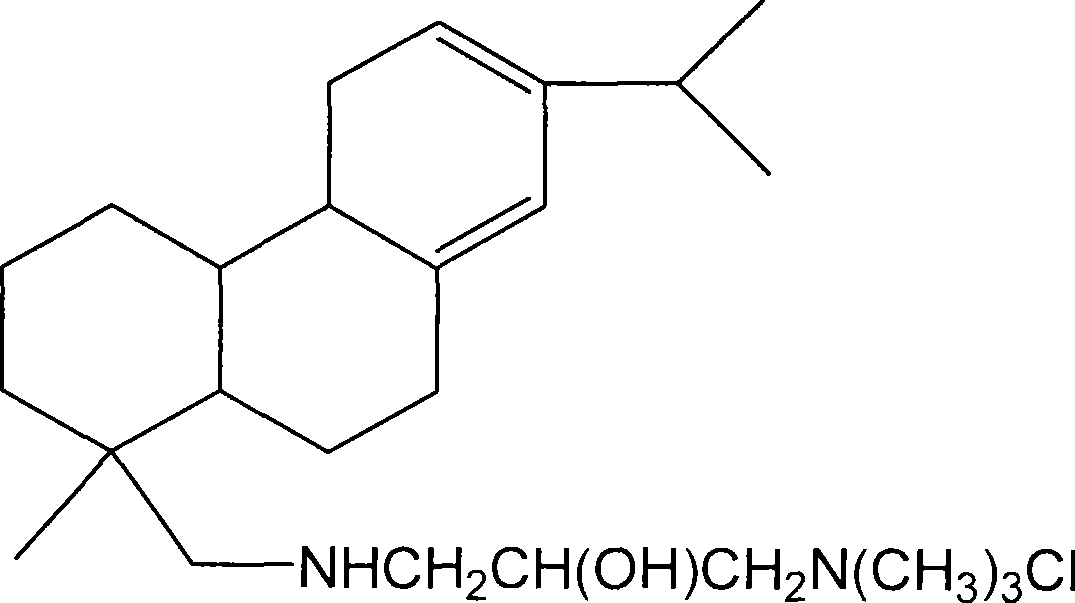

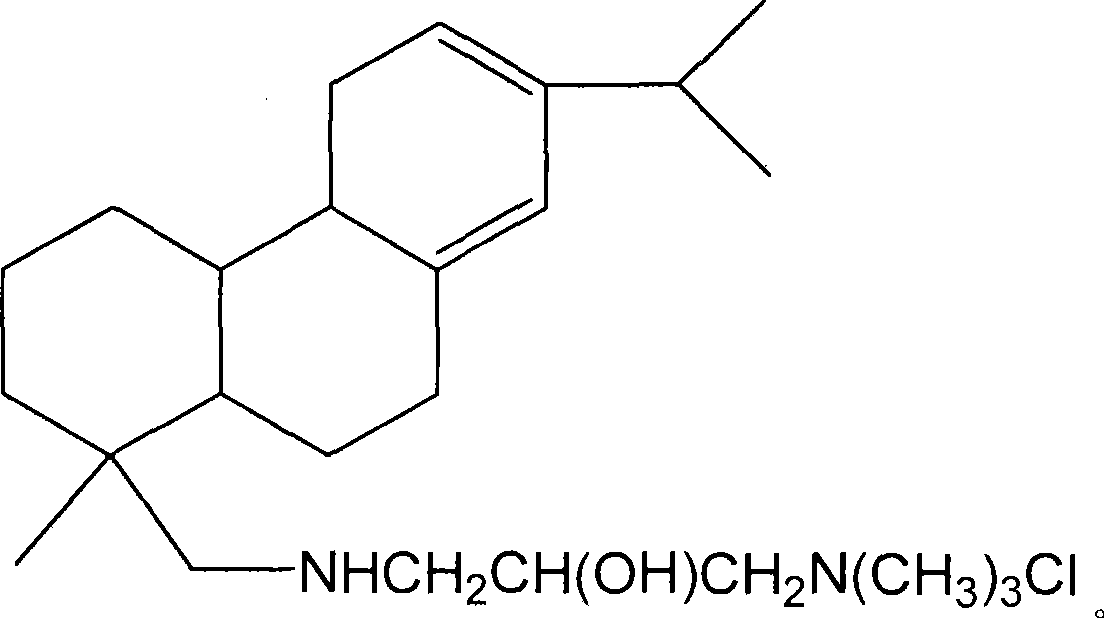

Method for preparing 3-rosin amino-2-hydroxypropyl trimethyl ammonium chloride

A technology of hydroxypropyltrimethylammonium chloride and epoxypropyltrimethylammonium chloride is applied in the field of preparing cationic surfactants containing rosin amine structure, which can solve the problem of low conversion rate of rosin amine and reaction steps Many, complex processes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 100 grams of rosin amine use 400 grams of 1,2-dichloroethane, dichloromethane, ethyl acetate, chloroform, N, N-dimethylformamide, acetonitrile in a mass ratio of 2:8:3:5: The composite solvent composed of 10:2 is dissolved to form a uniform solution, and then 100 grams of glycidyltrimethylammonium chloride and 3-chloro-2-hydroxypropyltrimethylammonium chloride are added in a mass ratio of 10:13. quaternizing reagent, and stirring to form a mixed material; add 50 grams of solid catalysts that are loaded with an acid-binding agent in the mixed material, wherein the carrier of the solid catalyst is made of 100 purpose alumina, 300 purpose silica gel, 150 purpose activated carbon by mass ratio 1 : 2: 3 composition, the acid-binding agent contained in the solid catalyst is composed of sodium carbonate, potassium carbonate, calcium carbonate, sodium bicarbonate, potassium bicarbonate, potassium hydroxide, sodium hydroxide, triethylamine, tripropylamine, tributyl The amine is ...

Embodiment 2

[0019] 100 grams of rosin amine use 800 grams of 1,2-dichloroethane, dichloromethane, ethyl acetate, chloroform, N, N-dimethylformamide, acetonitrile in a mass ratio of 5:10:7:5: The composite solvent composed of 10:6 is dissolved to form a uniform solution, and then 300 grams of glycidyltrimethylammonium chloride and 3-chloro-2-hydroxypropyltrimethylammonium chloride are added in a mass ratio of 1:13. quaternizing reagent, and stirring to form a mixed material; add 150 grams of solid catalysts that are loaded with an acid-binding agent in the mixed material, wherein the carrier of the solid catalyst is made of 300 purpose alumina, 300 purpose silica gel, 250 purpose activated carbon by mass ratio 2 : 7:9 composition, the acid binding agent contained in the solid catalyst is composed of sodium carbonate, potassium carbonate, calcium carbonate, sodium bicarbonate, potassium bicarbonate, potassium hydroxide, sodium hydroxide, triethylamine, tripropylamine, tributylamine The amin...

Embodiment 3

[0021] 100 grams of rosin amine use 1200 grams of 1,2-dichloroethane, dichloromethane, ethyl acetate, chloroform, N, N-dimethylformamide, acetonitrile in a mass ratio of 8:3:9:5: The composite solvent composed of 12:3 is dissolved to form a uniform solution, and then 50 grams of glycidyltrimethylammonium chloride and 3-chloro-2-hydroxypropyltrimethylammonium chloride are added in a mass ratio of 15:7. quaternizing reagent, and stirring to form a mixed material; add 80 grams of solid catalysts that are loaded with an acid-binding agent in the mixed material, wherein the carrier of the solid catalyst is made of 500 purpose alumina, 400 purpose silica gel, 400 purpose gac by mass ratio 10 :7:2 composition, the acid-binding agent contained in the solid catalyst is composed of sodium carbonate, potassium carbonate, calcium carbonate, sodium bicarbonate, potassium bicarbonate, potassium hydroxide, sodium hydroxide, triethylamine, tripropylamine, tributylamine The amine is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com