Preparation method of gene coatings of medical device

A medical device and gene technology, applied in the field of preparation of gene coatings, can solve the problems of increasing matrix inflammation and restenosis, achieve the effect of avoiding inflammation and restenosis, meeting clinical needs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

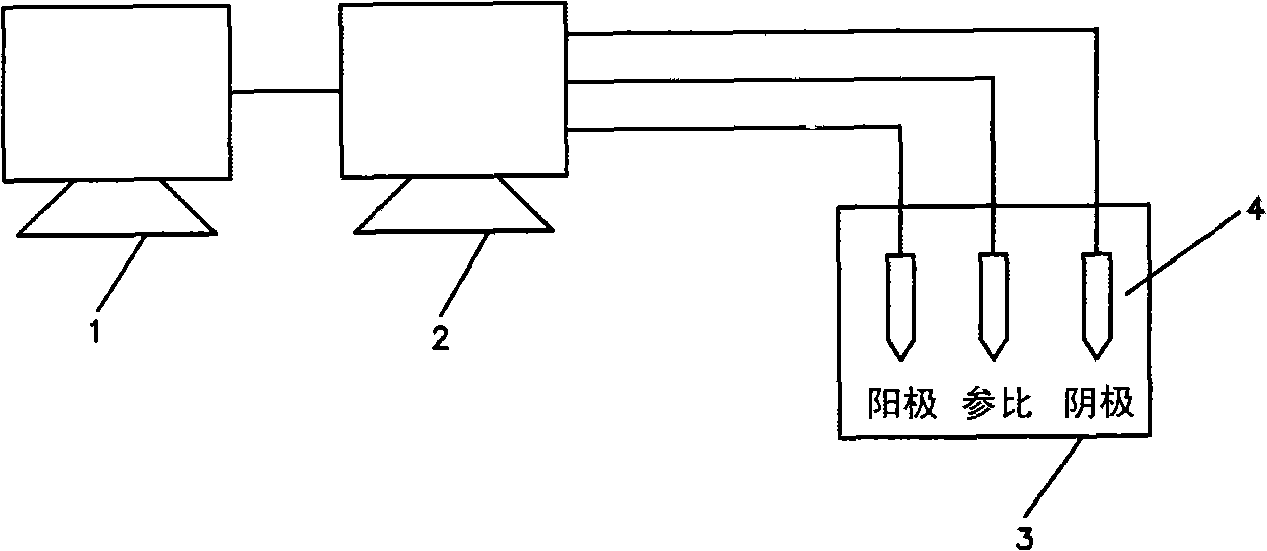

[0052] The preparation of embodiment 1 iNOS gene coating nanopore support

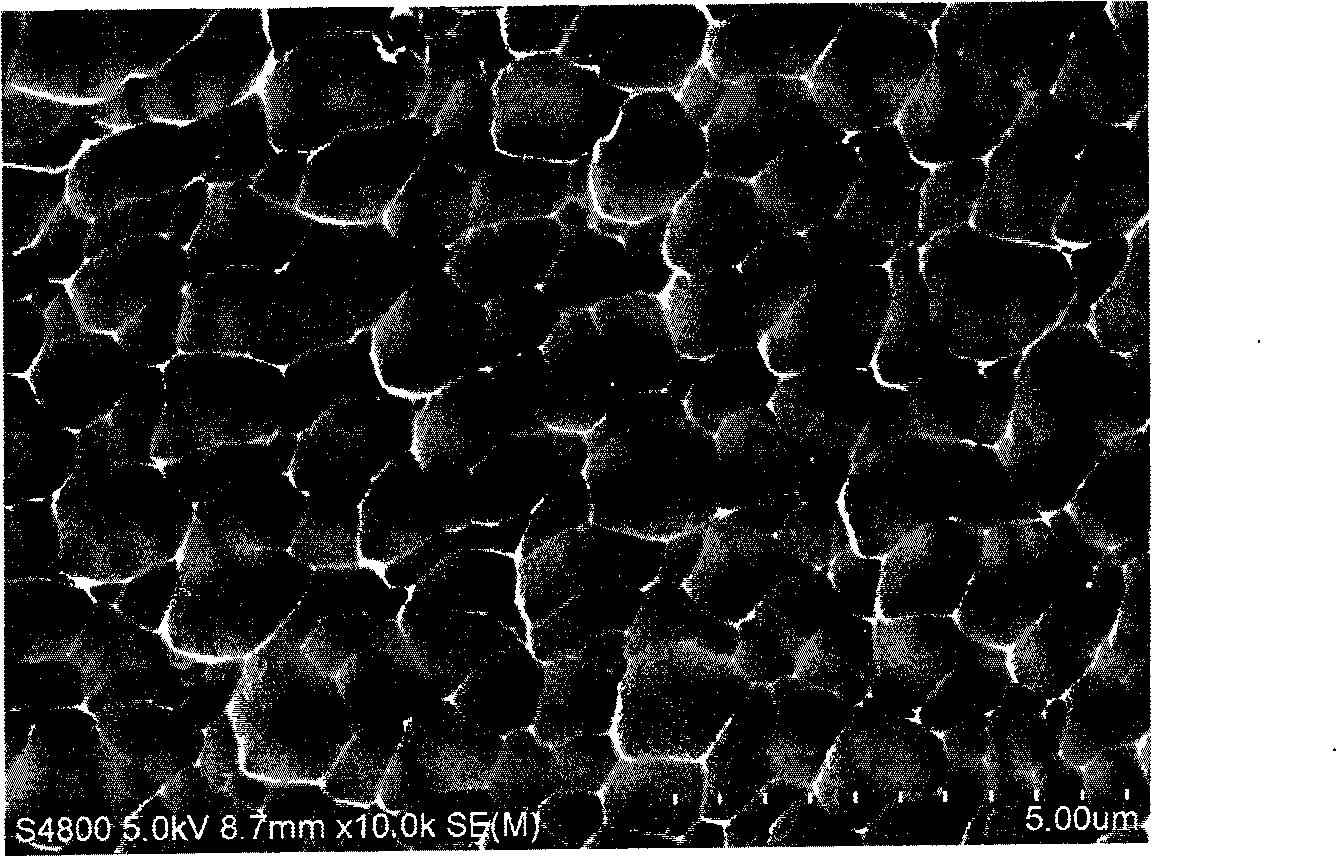

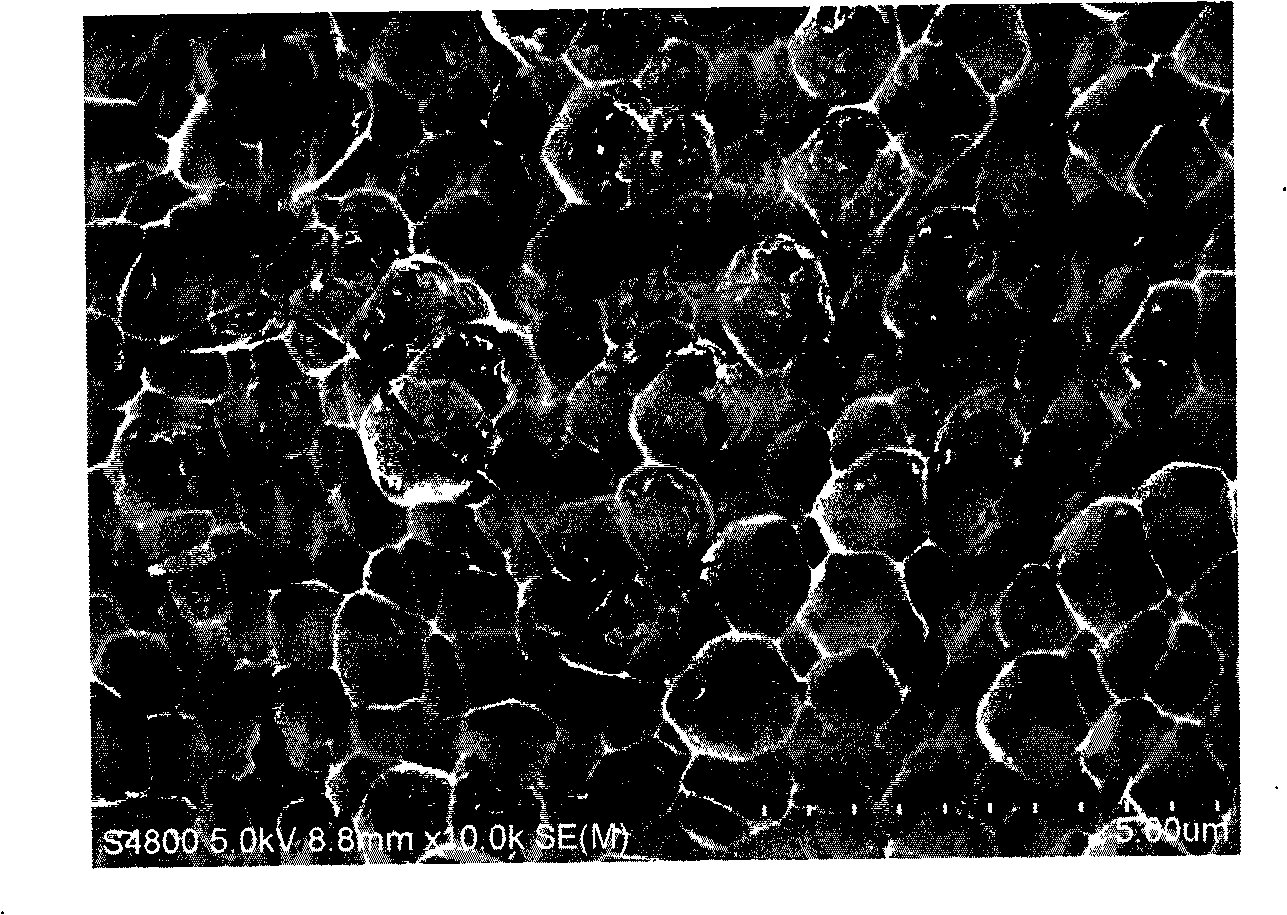

[0053] After the 316L stainless steel alloy is polished, it is laser-engraved into a vascular stent, and then through the combination of acid corrosion and anodic oxidation, the drug-loading holes are directly prepared on the local surface of the raw material of the device body, and the diameter of the holes is 200-300nm.

[0054] Then make the gene or oligonucleotide coating bioscaffold according to the following steps:

[0055] 1. Cleaning of the surface of the bracket body:

[0056] (1) Grinding the surface of the bracket body with an abrasive belt, mechanically removing oxides on the surface, and adjusting the surface roughness;

[0057] (2) Use ultrasonic waves to clean with 75% medical ethanol solution, 99.5% acetone solution, and deionized water in sequence. The ultrasonic frequency is 100KHz, and the cleaning time is 10 minutes;

[0058] (3) Soak the stent body in a 30g / L, 80°C sodium hydroxi...

Embodiment 2

[0067] Preparation of iNOS gene and rapamycin co-coated bioscaffold with nanopores

[0068] The cobalt-chromium alloy material is selected and polished, and then laser-engraved into a vascular stent; then, through the combination of acid corrosion, micro-arc oxidation and micro-arc nitriding, drug-loading holes are prepared on the surface of the stent, and the holes are drug-loading grooves. The diameter of the hole is 100-200nm. The gene-coated bioscaffold was prepared according to the following steps:

[0069] 1. Cleaning of the surface of the bracket body:

[0070] (1) Grinding the surface of the bracket body with an abrasive belt, mechanically removing oxides on the surface, and adjusting the surface roughness;

[0071] (2) Use ultrasonic waves to clean with 75% medical ethanol solution, 99.5% acetone solution, and deionized water in sequence. The ultrasonic frequency is 60KHz, and the cleaning time is 15 minutes;

Embodiment 3

[0082] Preparation of iNOS gene and rapamycin co-coated bioscaffold with nanopores

[0083] After the nickel-chromium alloy material is polished, it is carved into a vascular stent with a laser; then, through the combination of acid corrosion, micro-arc oxidation and micro-arc nitriding, drug-loading holes are prepared on the surface of the stent, and the holes are drug-loading grooves. The diameter of the hole is 150-300nm. The gene-coated bioscaffold was prepared according to the following steps:

[0084] 1. Cleaning of the surface of the bracket body:

[0085] (1) Grinding the surface of the bracket body with an abrasive belt, mechanically removing oxides on the surface, and adjusting the surface roughness;

[0086] (2) Use ultrasonic waves to clean with 75% medical ethanol solution, 99.5% acetone solution, and deionized water in sequence. The ultrasonic frequency is 28KHz, and the cleaning time is 15 minutes;

[0087] (3) Soak the stent body in a 30g / L, 100°C sodium hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com