Composite sustained-release urea of organic materials and method of producing the same

An organic material and slow-release urea technology, applied in the agricultural field, can solve the problems of low production process cost, poor controlled-release performance, and unsatisfactory nutrient slow-release effect, so as to reduce agricultural costs, enhance the slow-release effect, and uniform product particles smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

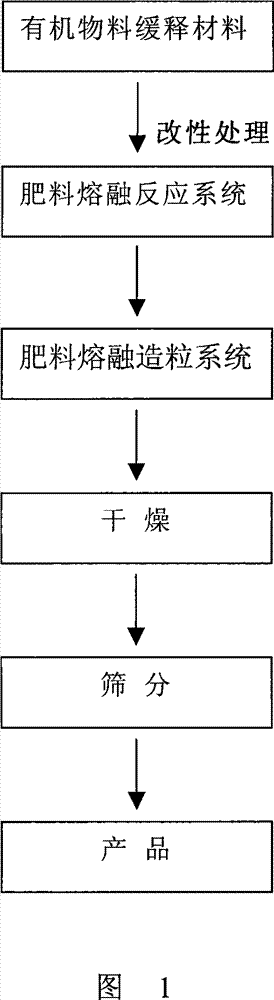

Image

Examples

Embodiment 1

[0024] The weathered coal material is crushed, sieved (≥80 mesh), and fermented and composted (for the method, see "Solid Waste Composting and Organic Compound Fertilizer Production", edited by Li Guoxue and Zhang Fusuo, 2000, Beijing: Chemical Industry Press ), after being decomposed, the organic material is dried (water content 2~3%), pulverized (fineness ≥ 100 mesh), and the urine or molten urea before the industrial synthetic urea granulation is added in the ratio of 3: 7 by weight (temperature 125 DEG C, mass percentage concentration 96%), stirring and mixing, the heating steam pressure in the urea melting tank is 1.0MPa. Then send it to the high-tower spray granulation equipment for spray granulation. The steam pressure of the urine pipeline insulation is 0.25MPa, the temperature of the material in the granulator is 62°C, and the water content of the material after granulation is 3-5%. After granulation, enter the drying cylinder for drying, which is the finished produc...

Embodiment 2

[0026] Organic waste residues such as food factories, wood processing enterprises and paper industry lignin wastes are crushed, sieved (≥80 mesh), and fermented and composted (method as in Example 1), and the organic materials are dried after they are well decomposed ( water content 2-3%), pulverized (fineness ≥ 100 mesh), and added to the urine or molten urea (temperature 125°C, mass percentage concentration 96%) in the ratio of 2:3 by weight before granulation of industrially synthesized urea , stirring and mixing, the heating steam pressure in the urea melting tank is 1.0MPa, and then sent to the high-tower spray granulation equipment for spray granulation. The steam pressure of the urine pipeline insulation is 0.25MPa, the temperature of the material in the granulator is 62°C, and the water content of the material after granulation is 3-5%. After granulation, enter the drying cylinder for drying, which is the finished product. The inlet temperature of the dryer is 150°C a...

Embodiment 3

[0028] Organic materials such as crop stalks and chaff are crushed, sieved (≥80 mesh), and fermented and composted (as in Example 1). degree ≥ 100 mesh), add the urine or molten urea (temperature 125°C, mass percentage concentration 96%) in the ratio of 1:1 by weight before industrial synthetic urea granulation, stir and mix, and heat steam in the urea melting tank The pressure is 1.0MPa, and then sent to the high-tower spray granulation equipment for spray granulation. The steam pressure of the urine pipeline insulation is 0.25MPa, the temperature of the material in the granulator is 62°C, and the water content of the material after granulation is 3-5%. After granulation, enter the drying cylinder for drying, which is the finished product. The inlet temperature of the dryer is 140°C and the outlet temperature is 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com