Rhodium-tellurium intermetallic compound particle, method for producing the same, and use of the same

A technology for intermetallic compounds and manufacturing methods, which can be used in chemical instruments and methods, metal processing equipment, chemical/physical processes, etc., and can solve problems such as differences in the degree of reduction of metal salts, heterogeneous alloy particles, and difficulty in synthesizing intermetallic compounds. , to achieve the effect of less deterioration over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0259] Add 0.15 mol of rhodium chloride and 0.30 mmol of 1,3-dihydroxy-4-(2-pyridyl azo)benzene (1,3-dihydroxy-4-(2-pyridylazo)benzene) in distilled water (referred to as PAR: Formula C 11 h 9 o 2 N 3 ), then add sodium hydroxide, the pH is adjusted to 13, rhodium chloride and PAR are dissolved thus, prepare 10ml rhodium-containing solution. Let this solution be A solution.

[0260] Further, after adding and dissolving 0.40 mmol of citric acid in distilled water, 0.10 mmol of telluric acid was added and dissolved therein to prepare 10 ml of a tellurium-containing solution. Let this solution be B solution.

[0261] Then, the A solution and the B solution were mixed, and distilled water and sodium hydroxide were added thereto, the pH was adjusted to 13, the total amount was 48ml, then mixed with enough time, and then 2ml of 80% hydrazine hydrate solution was added, Reduction was carried out at 70°C for 3 hours.

[0262] In a nitrogen atmosphere, the black powder obtained ...

Embodiment 2

[0267] After raising the temperature of the compound powder of Example 1 to 150° C. in a nitrogen gas stream, the flowing gas was switched from nitrogen to hydrogen, and the temperature was further raised to 400° C. and kept for 2 hours, thereby performing heat treatment. Thereafter, the flowing gas was switched to nitrogen gas again, and cooled to room temperature to obtain a compound powder (compound powder of Example 2).

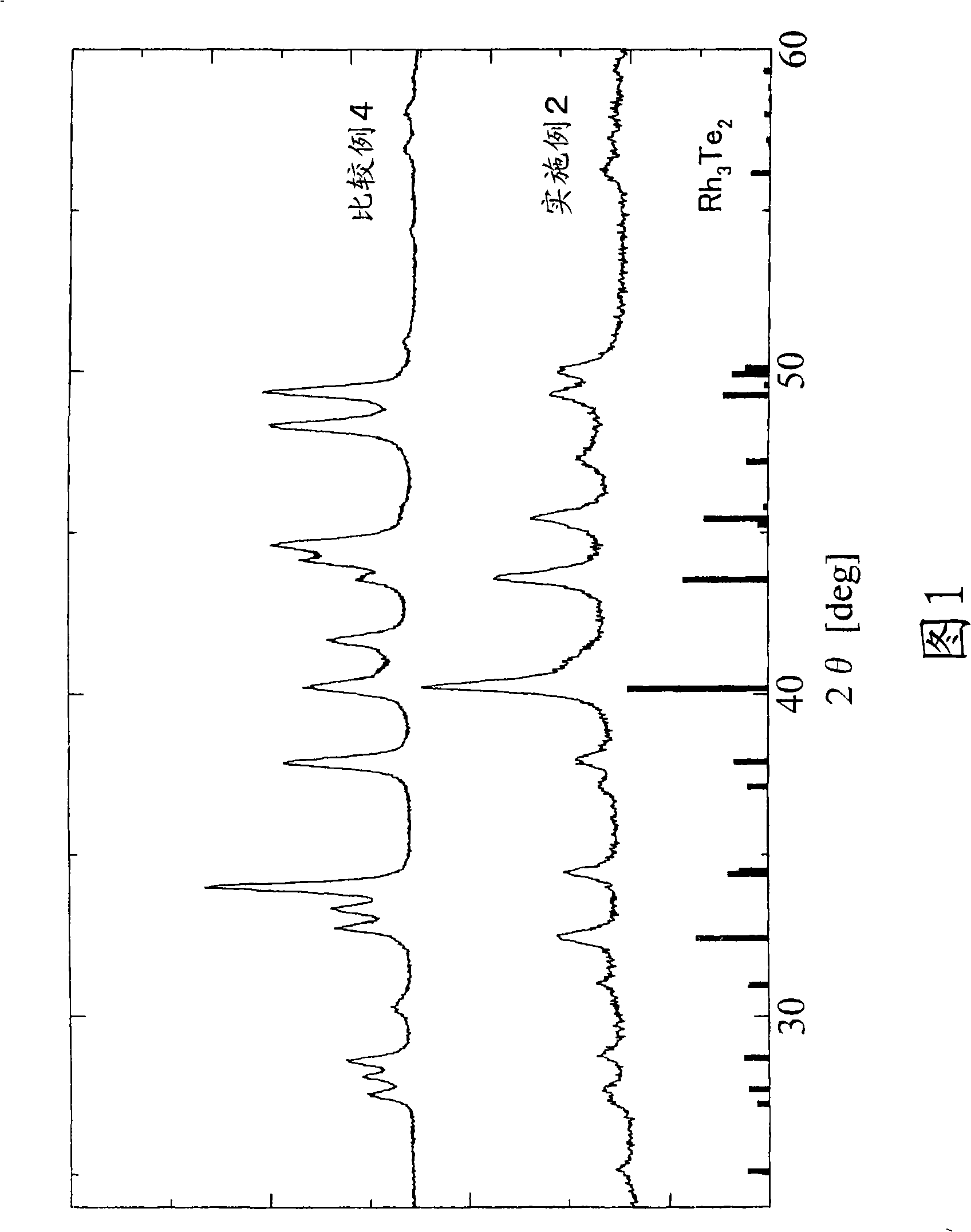

[0268] The compound powder of Example 2 was subjected to powder X-ray diffraction measurement. The obtained powder X-ray diffraction pattern was compared with Rh 3 Te 2 The standard peaks together are shown in figure 1 . Depend on figure 1 It can be clearly seen that the powder X-ray diffraction pattern of the compound powder of Example 2 is basically consistent with the standard peak, thus it can be known that the compound powder of Example 2 is an intermetallic compound, and the compound powder is a high-purity Rh 3 Te 2 .

Embodiment 3

[0270] 0.15 mol of rhodium chloride and 0.45 mmol of thiosalicylic acid were added and dissolved in distilled water, and then sodium hydroxide was added to adjust the pH to 13, thereby preparing 10 ml of a rhodium-containing solution. Let this solution be A solution.

[0271] Separately, after adding and dissolving 0.15 mmol of sodium tellurite in distilled water, sodium hydroxide was added to adjust the pH to 13, thereby preparing 10 ml of a tellurium-containing solution. Let this solution be B solution.

[0272] Separately, after adding and dissolving 2 mmol of sodium borohydride in distilled water, sodium hydroxide was added to adjust the pH to 13, thereby preparing 10 ml of a solution containing sodium borohydride. This solution is referred to as C solution.

[0273] Then, mix solution A and solution B, add distilled water and sodium hydroxide to it, and adjust the pH to 13, the total amount is 48ml, then mix with sufficient time, then add solution C, and carry out at 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com