Tea leaf and manufacturing method and applications thereof

A technology of tea and raw materials, which is applied in the field of tea and its preparation and application, and can solve problems such as unfavorable health and unreported natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1: Thick-axis green tea was prepared from the fresh leaves of Phyllostachys glabrata as raw material.

[0068] (1) According to the standard tea-making process, pick the fresh leaves of C. glabrata, heat them up instantly, knead them manually or mechanically, and dry them to obtain thick-stem green tea made of C. glabrata.

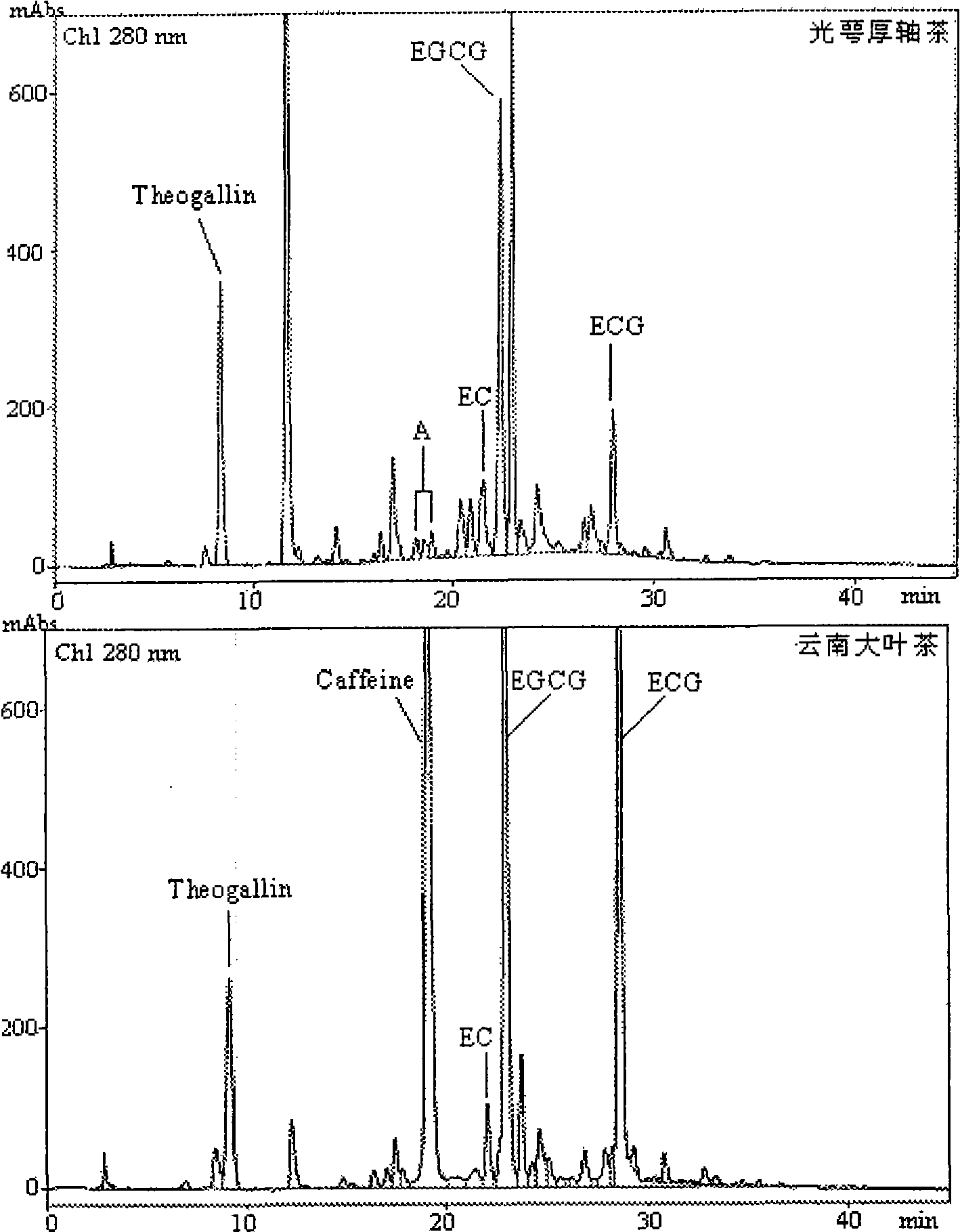

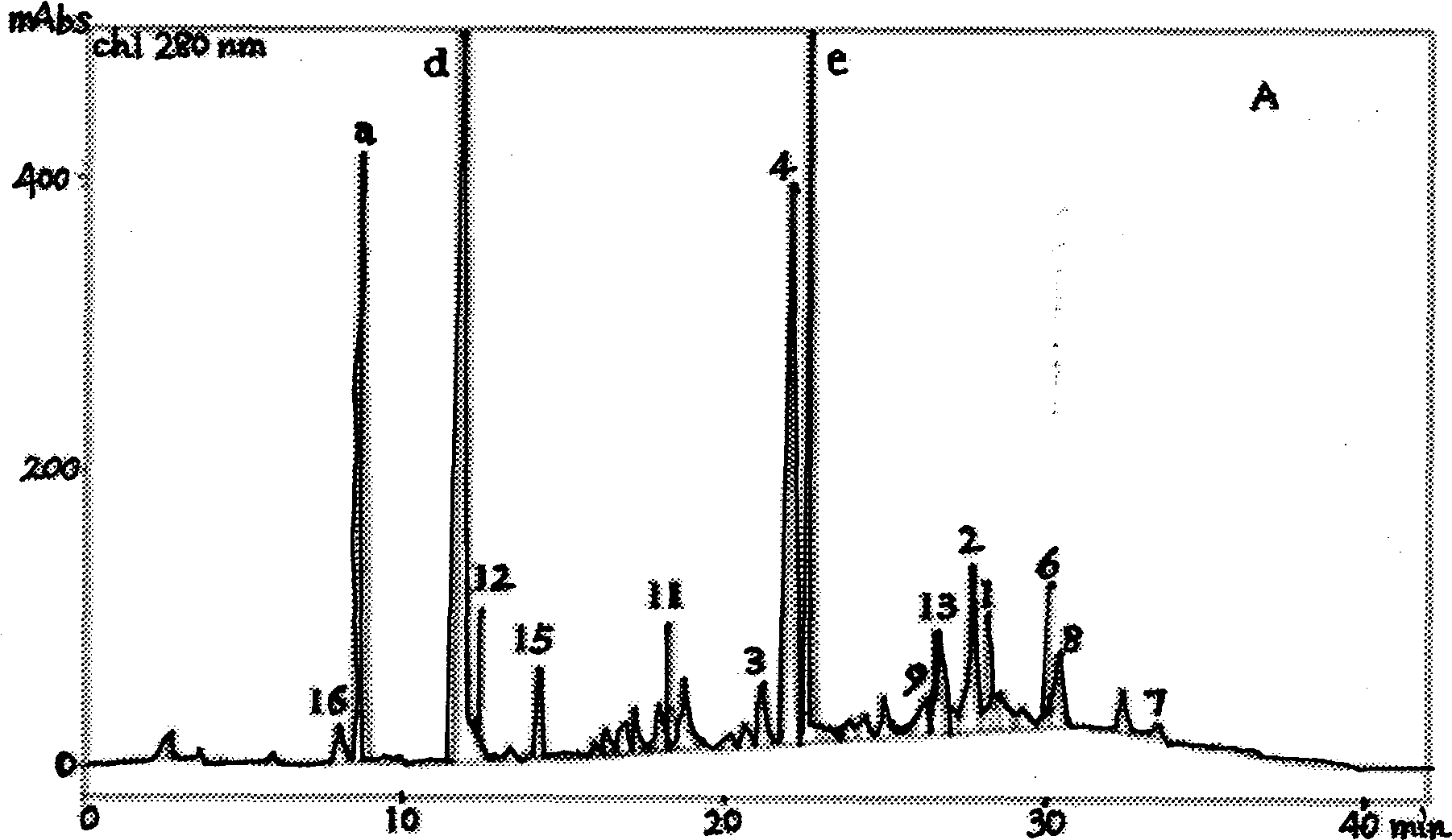

[0069] (2) The composition and content of tea polyphenols were detected by high pressure liquid chromatography (HPLC). HPLC analysis condition and result are as follows:

[0070] Instruments and reagents: Shimadzu 10AT high performance liquid chromatography, high-pressure binary pump, SPD-10Avp diode array detector, CLASS-LC10 workstation, chromatographically pure acetonitrile, ultrapure water. (1) Chromatographic conditions: the stationary phase is Agilent Zorbax SB-C18 (4.6×250mm, 5 μm) chromatographic column, the mobile phase is acetonitrile-0.34% phosphoric acid water gradient elution (0-45min, 4%-40% acetonitrile), the flow rate 1mL / m...

Embodiment 2

[0078] Example 2: Preparing Thick-shaft Sun-dried Green Tea with Fresh Leaves of Thick-shaft Tea

[0079] (1) According to the standard tea-making process, the fresh leaves of C. glabrata are picked, immediately heated to fix green leaves, manually or mechanically rolled, and dried in the sun to obtain thick-stem sun-dried green tea made of C. glabrata.

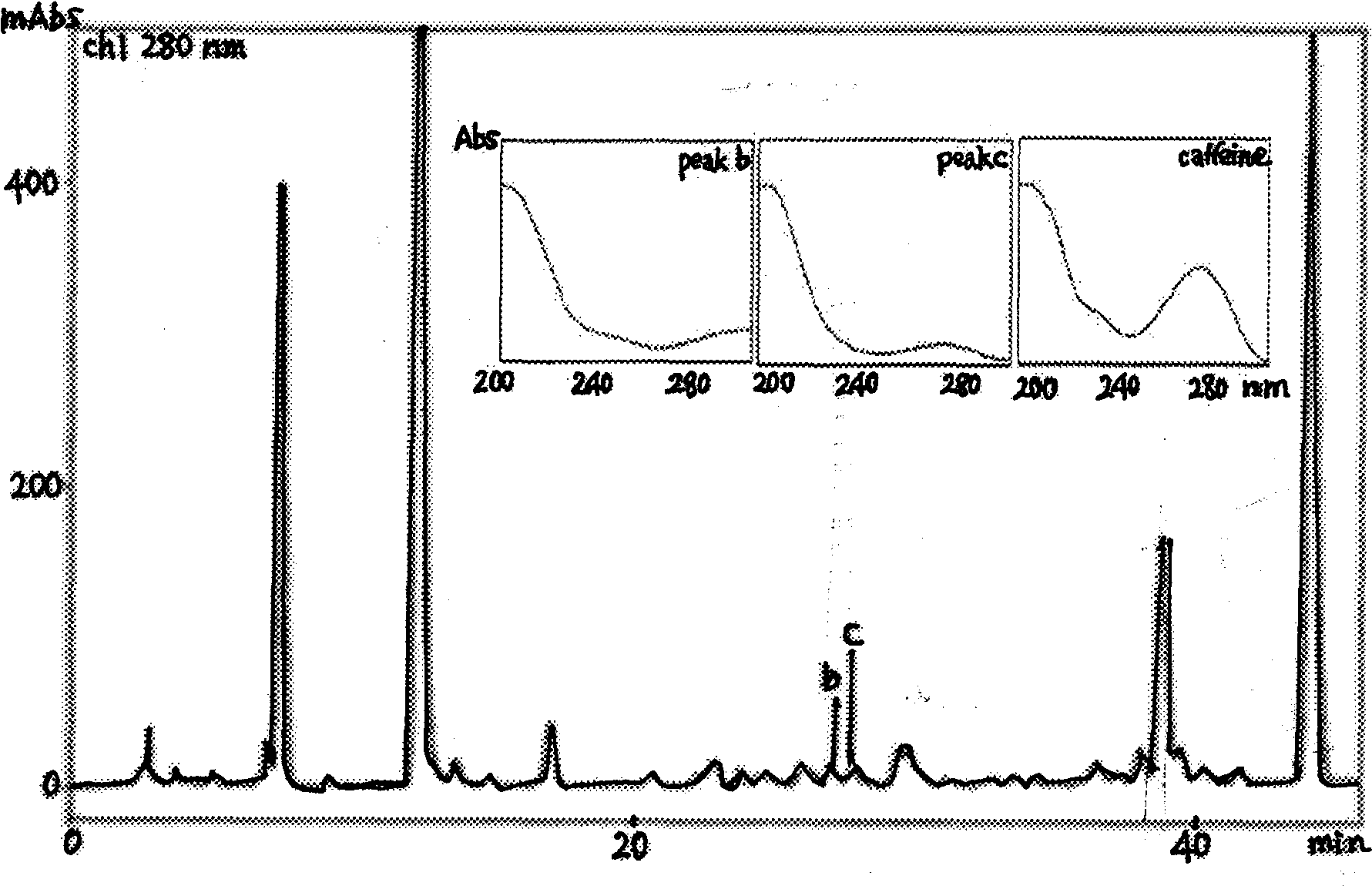

[0080] (2) High-pressure liquid chromatography (HPLC) and liquid chromatography-mass chromatography (LC-MS) were used to detect tea polyphenols, caffeine and theophylline and other components.

[0081] The analysis shows that the sun-dried green hair tea made from the fresh leaves of C. glabrata contains rich polyphenols and does not contain caffeine and theophylline. The HPLC analysis conditions are the same as in Example 1, and the results are shown in Table 4.

[0082] Table 4. Content Analysis of Main Components of Thick Shaft Sun-dried Green Tea

[0083]

Embodiment 3

[0084] Example 3: Tea beverages were prepared from tea leaves with thick shafts of calyx glabrata.

[0085] (1) Teabags and instant teas are made from the tea leaves made from the fresh leaves of C.

[0086] The detection results of high-pressure liquid chromatography (HPLC) and liquid chromatography-mass spectrometry (LC-MS) showed that the tea drink was rich in polyphenols and did not contain caffeine and theophylline. HPLC analysis condition is with embodiment 1, its result table 5:

[0087] Table 5. Content Analysis of Main Components of Thick Shaft Tea Beverage

[0088]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com