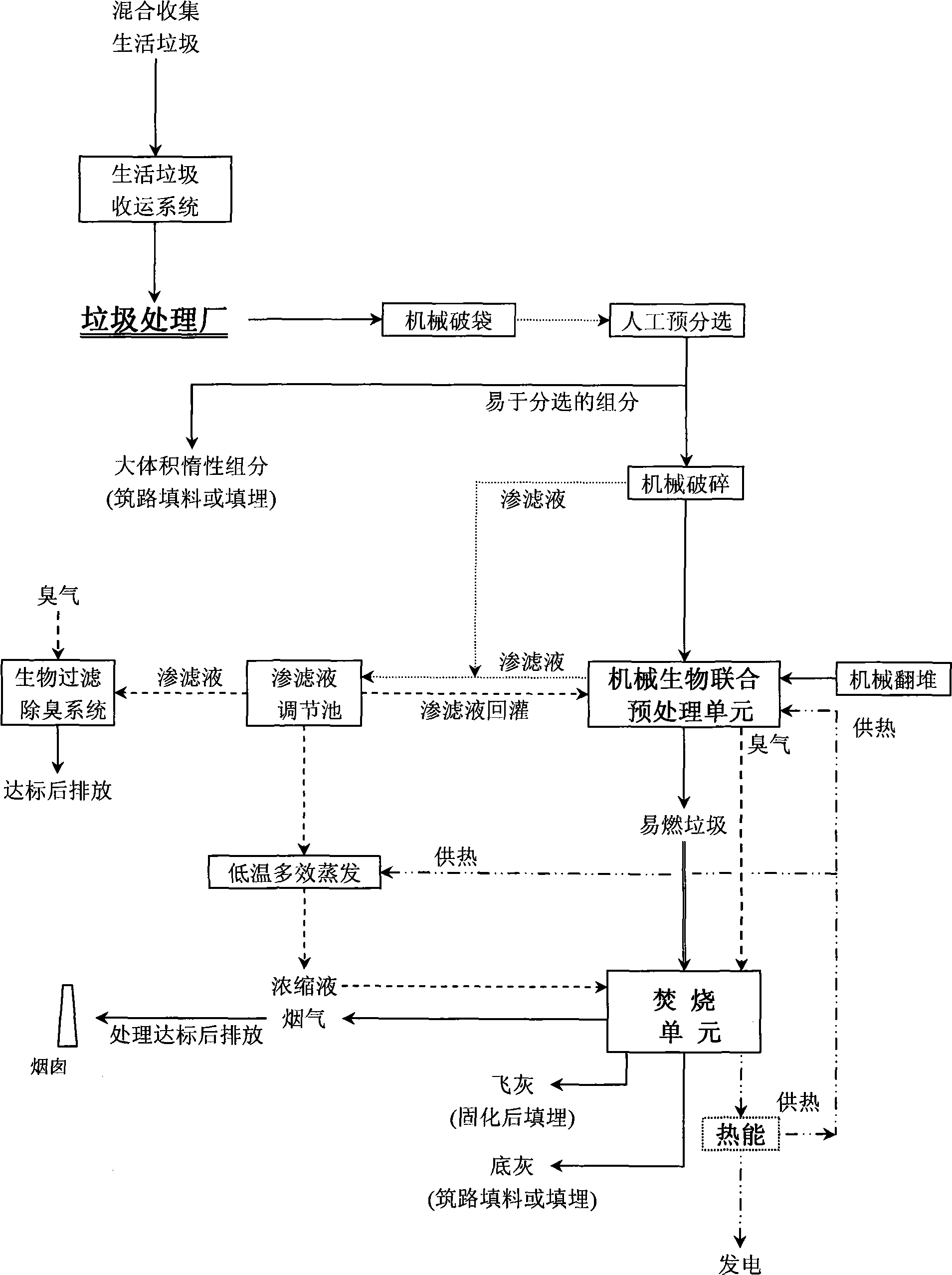

Domestic waste incineration process based on mechanical biological joint pretreatment and system thereof

A technology for domestic waste incineration and domestic waste, which is used in joint combustion mitigation, solid waste removal, incinerators, etc. Small land area, low cost and high heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

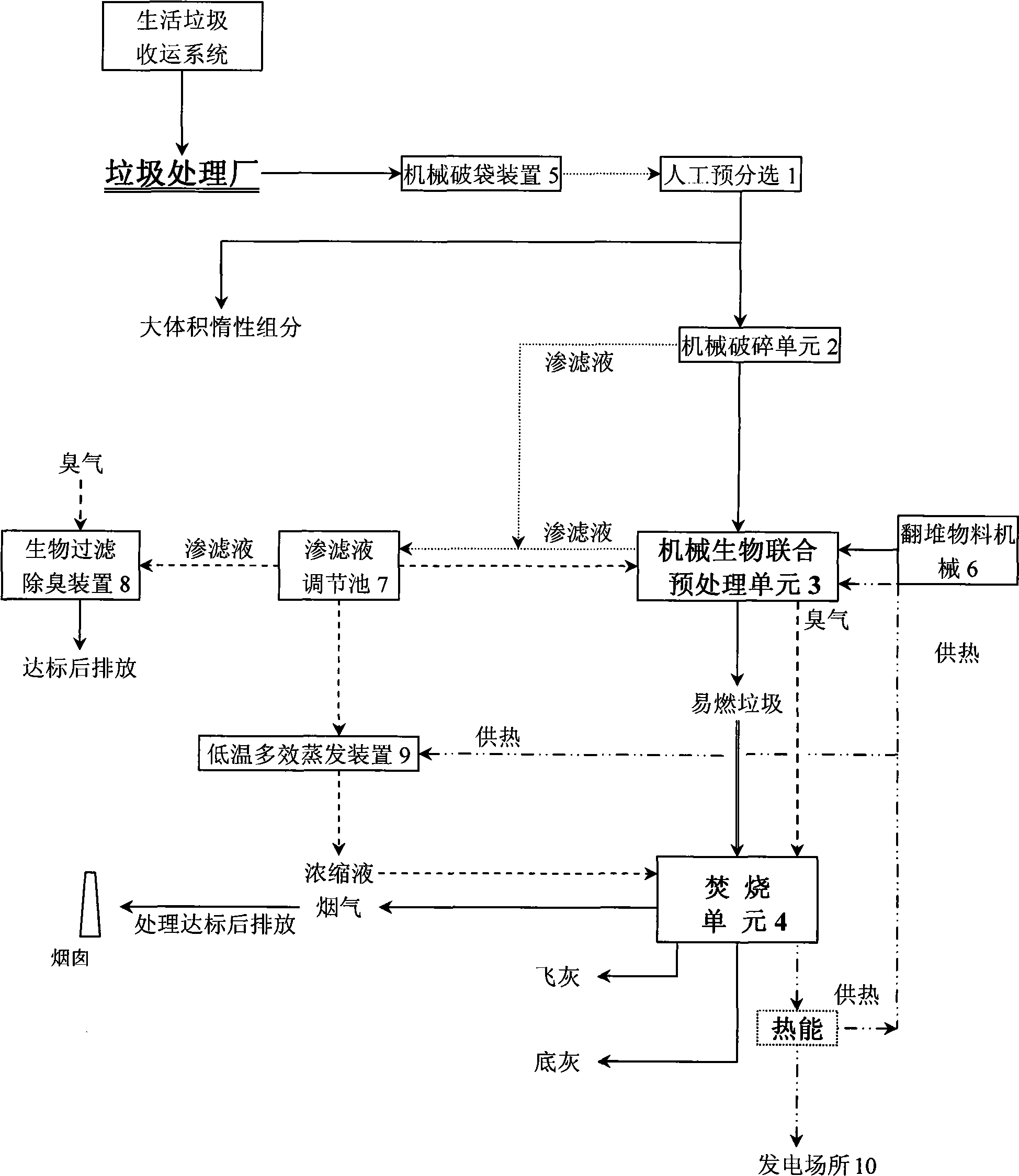

[0030] Such as figure 2 The shown domestic waste treatment system based on combined mechanical and biological pretreatment: includes manual pre-sorting unit, mechanical crushing unit, mechanical and biological combined pretreatment unit, and incineration unit; the manual pre-sorting unit is equipped with a mechanical bag breaking device, and the manual pre-sorting unit is The output of the sorting unit is transported to the mechanical crushing unit, and the output of the mechanical crushing unit is transported to the combined mechanical and biological pretreatment unit. The turning material machine is located in the processing unit to turn the material pile, and is equipped with a ventilation device to connect to the odor collection. unit, the discharge port of the combined mechanical and biological pretreatment unit is connected to the incineration unit to transport the material into the incineration unit, the liquid outlet of the combined mechanical and biological pretreatme...

Embodiment 2

[0032] Adopt the system of embodiment 1 to process the mixed collection of domestic waste, which mainly includes plastics, rubber, wood and bamboo, paper, lime soil, brick pottery, metal, glass, textiles and kitchen organic matter, etc. The specific process is as follows: :

[0033] 1) Manual pretreatment: After the domestic waste collected by the domestic waste collection and transportation system is weighed by the truck scale, the waste is poured into a closed reinforced concrete garbage storage tank, and the leachate is collected at the bottom of the garbage storage tank, and the storage tank keeps micro-negative Press down to prevent odor from leaking out. Use garbage bag breaking equipment to mechanically break bags of mixed garbage. After breaking bags, carry out manual pre-sorting on the conveyor belt to sort out large-volume bricks and pottery and other inert components to avoid adverse effects of large-volume inert components on subsequent processes.

[0034] 2) Mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com