High efficient treatment method of alcoholic fermentation waste liquor and device thereof

A treatment method and technology of alcohol waste liquid, which is applied in the production of hydrogen, etc., can solve the problems of high water content, unpleasant smell, and high heat consumption of alcohol waste liquid, and achieve the goals of shortening the processing cycle, saving resources, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

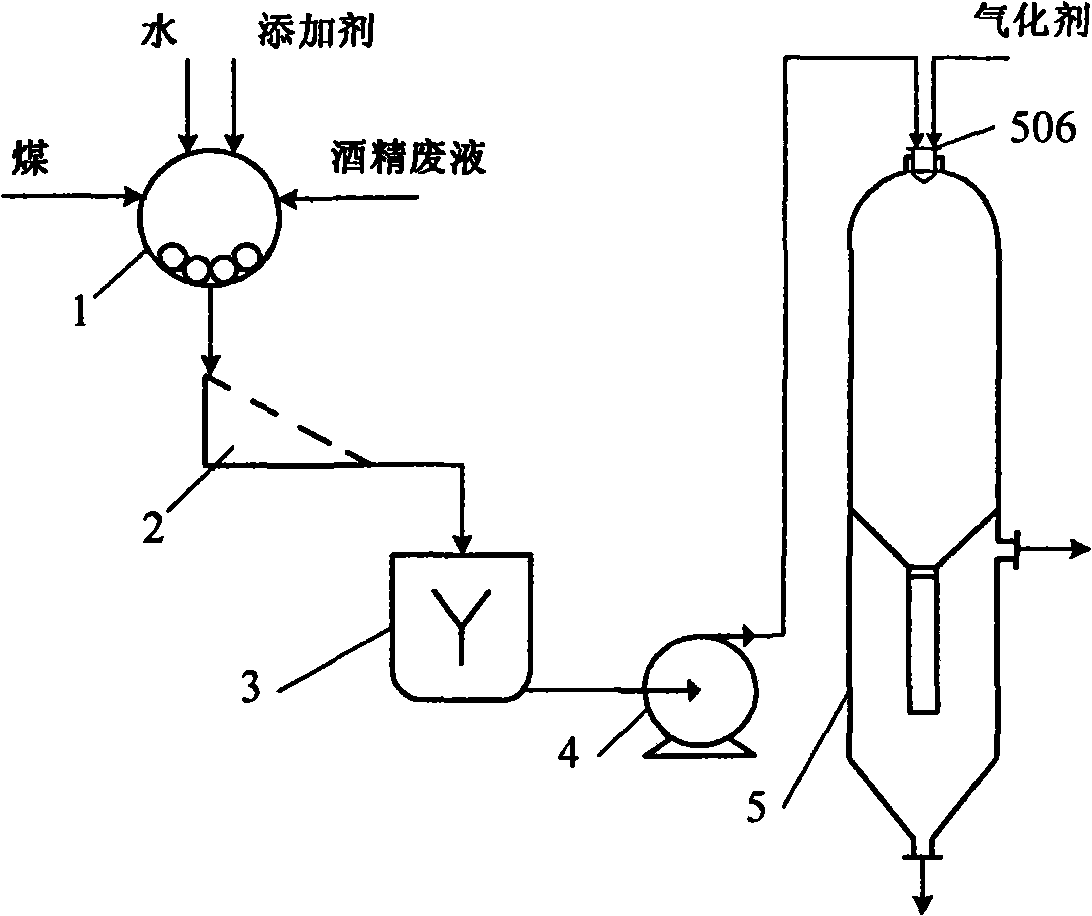

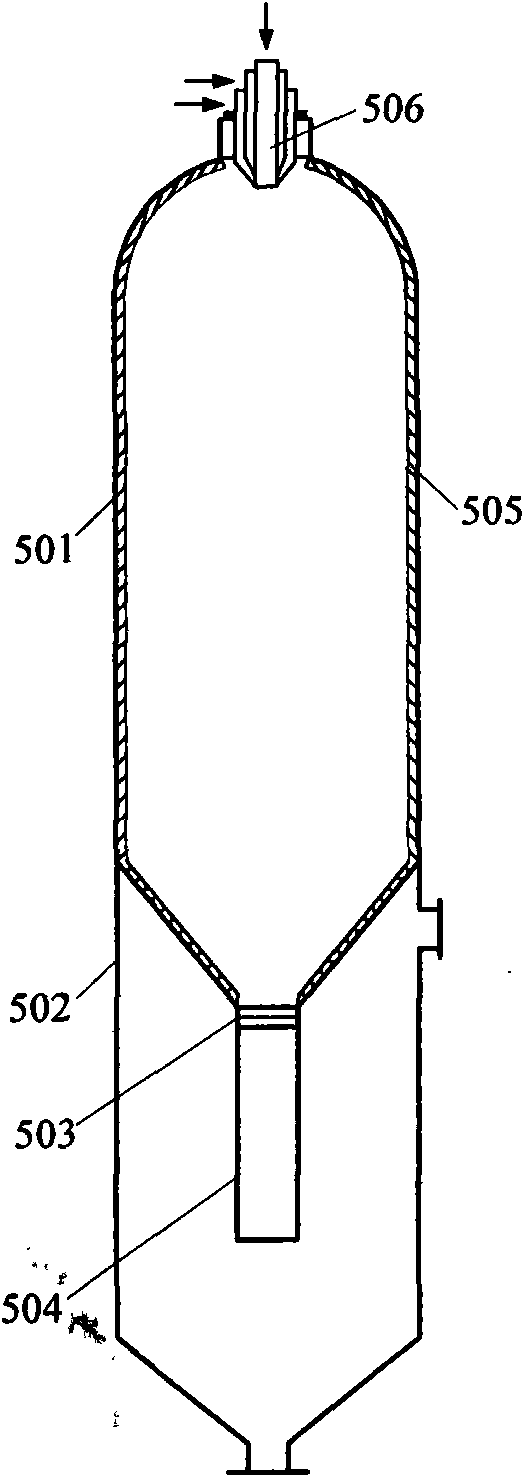

[0024] use figure 1 process and figure 2 The entrained entrained gasifier 5, wherein the nozzle 506 is provided with three channels.

[0025] The waste liquid with a water content of 96% (weight) discharged from the bottom of the crude distillation tower of a cassava fermentation ethanol plant is collected and enters the ball mill 1 with a flow rate of 5.81t / h through pumps and pipelines; at the same time, the particle size is less than 10mm and the water content is 7.00%. (weight), ash content of 5.35% (weight), ash melting point of 1179 ° C, carbon content of 78.35% (weight, dry basis), hydrogen content of 4.75% (weight, dry basis) of coal with a flow rate of 50.00t / h, The flow rate of fresh water is 18.64t / h, and additive is sent into the ball mill 1 with the flow rate of 0.47t / h. Cassava alcohol waste liquid, coal, water and a small amount of additives are ground and uniformly mixed in ball mill 1, and finally form solid particle particle diameter after vibrating screen...

Embodiment 2

[0027] Adopt the flow process identical with embodiment 1, the waste liquid of the water content 96% (weight) that alcohol waste liquor adopts the crude distillation column bottom discharge of certain cassava fermentation ethanol plant, flow rate is 1.13t / h; The water content of coal 10.00% ( weight), ash content 10.36% (weight), ash melting point 1243°C, carbon element content 71.18% (weight, dry basis), hydrogen element content 6.17% (weight, dry basis), flow rate 10.00t / h; fresh water flow rate is 2.84t / h, and the additive flow rate is 0.09t / h.

[0028] The cassava alcohol waste liquid coal slurry has a solid content of 65% (weight) and an apparent viscosity of 1050mPa.s.

[0029] The gasification agent is oxygen-enriched air (50% oxygen content), the pressure of the gasifier is 0.1MPa, and the temperature is 1306°C.

[0030] The dry basis composition of the obtained gas is (volume): 28.63% H 2 , 34.71% CO, 13.17% CO 2 , 28.63% N 2 , 0.13% H 2 S, 0.01% COS. The lower ...

Embodiment 3

[0032] Adopt the flow process identical with embodiment 1, the waste liquid of the water content 92% (weight) that alcohol waste liquid adopts the water content 92% (weight) discharge of some corn fermentation alcohol plant crude distillation tower bottom, flow rate is 3.56t / h; The water content of coal 5.00% ( weight), ash content 7.88% (weight), ash melting point 1218°C, carbon element content 73.84% (weight, dry basis), hydrogen element content 4.26% (weight, dry basis), flow rate is 30.00t / h; fresh water flow rate It is 14.61t / h, and the additive flow rate is 0.28t / h.

[0033] The solid content of the corn alcohol waste liquid coal slurry is 60% (weight), and the apparent viscosity is 980mPa.s.

[0034] The gasification agent is oxygen-enriched air (oxygen content 80%), the pressure of the gasifier is 3.0MPa, and the temperature is 1279°C.

[0035] The dry basis composition of the obtained gas is (volume): 30.54% H 2 , 45.82% CO, 15.76% CO 2 , 7.72% N 2 , 0.14% H 2 S,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap