Biomass gasification apparatus

A technology of biomass and gasification equipment, which is applied in the direction of gasification process, biofuel, educts, etc., can solve the problems of uneven distribution of gasification agent, failure, insufficient synthetic gas, etc., and achieve the goal of increasing the operating temperature range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

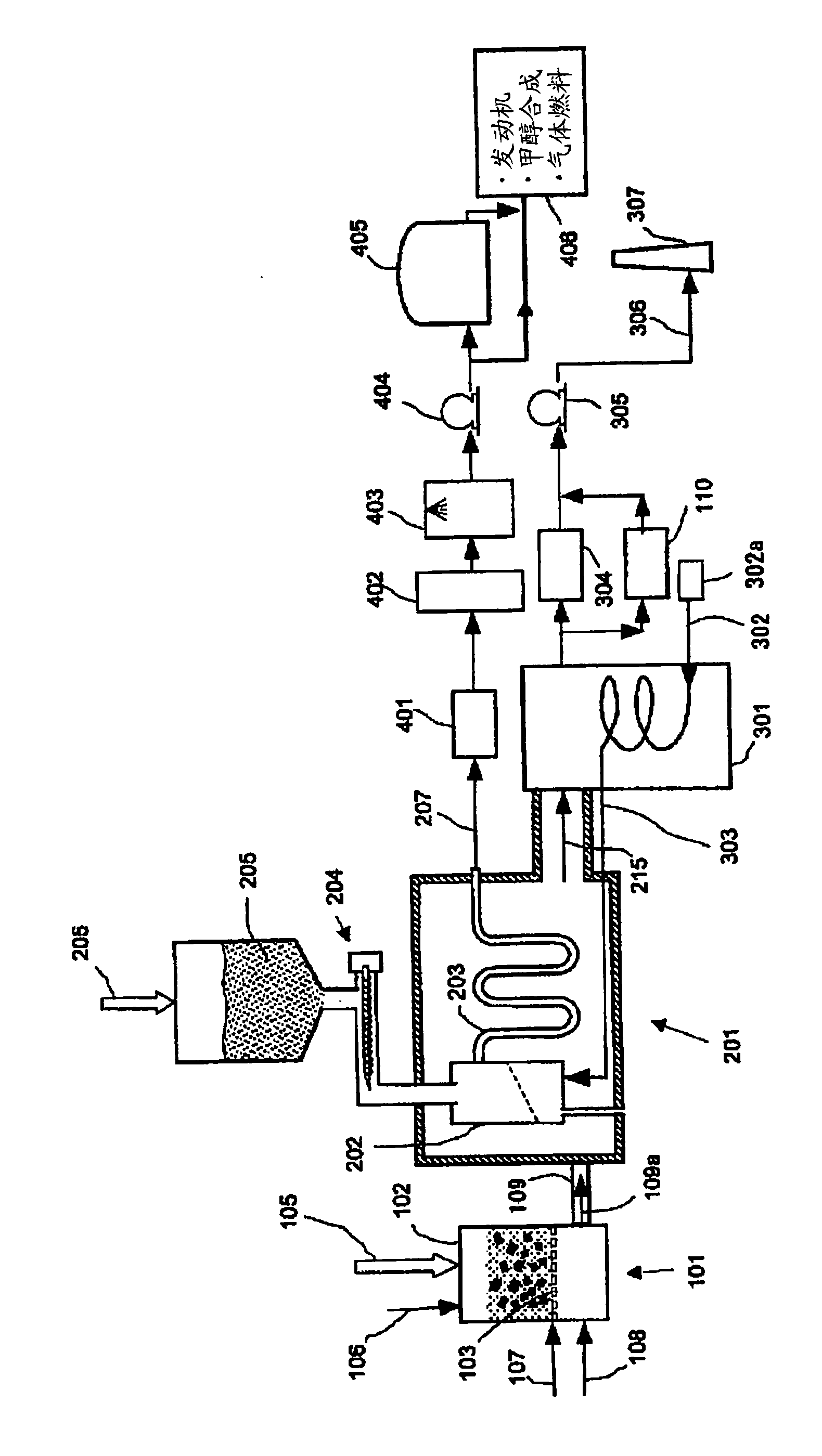

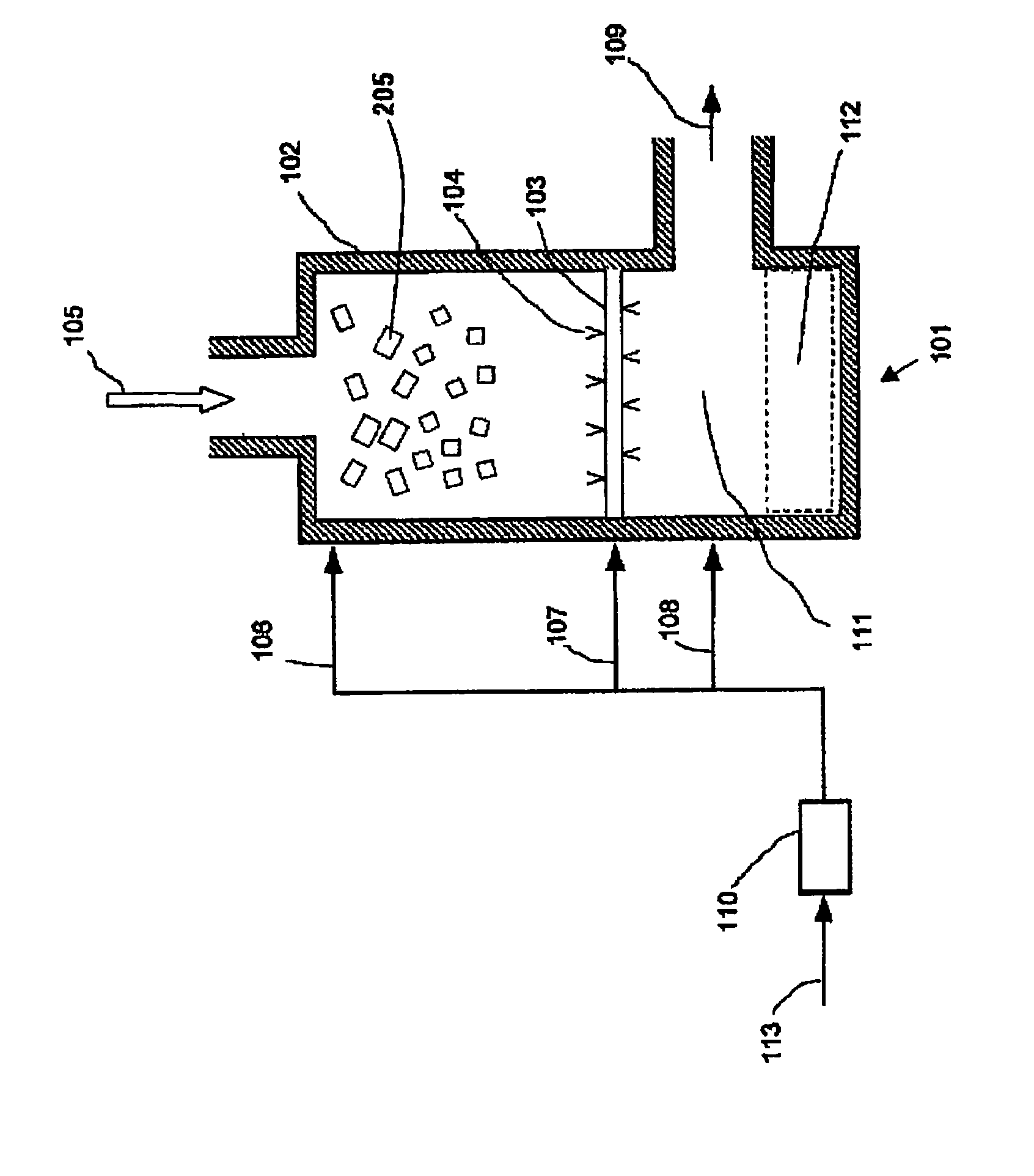

[0071] figure 1 An embodiment of the biomass gasification apparatus of the present invention is shown.

[0072] In the high-temperature combustion gas generator 101, biomass is burned to generate a high-temperature and clean combustion gas (indicated by an arrow) 109a exceeding 900°C. The combustion gas 109a is sent from the combustion gas supply line 109 to the gasification reaction device 201, and heats the primary gasification reaction chamber 202 arranged in the gasification reaction device 201 and the secondary gasification reaction chamber 202 connected to the primary gasification reaction chamber 202 from the outer wall surface. After the gasification reaction tube 203 , the waste gas 215 is formed and discharged from the gasification reaction device 201 .

[0073] The exhaust gas 215 generates superheated steam 303 in the waste heat boiler 301 . The superheated steam 303 is supplied from the gasification agent supply line 302 to the bottom of the primary gasification...

no. 2 Embodiment approach

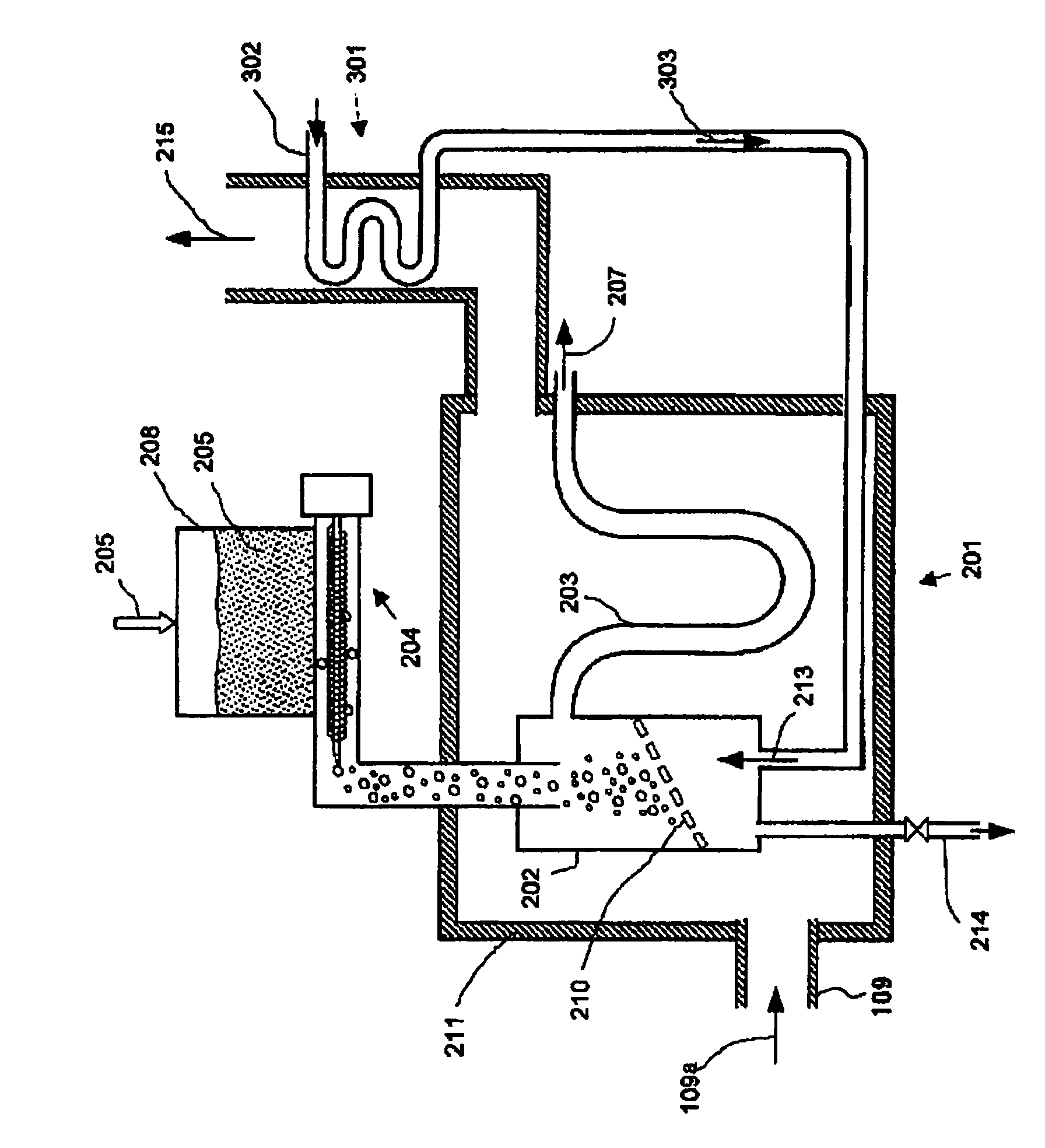

[0100] Figure 5 It is a schematic diagram of a gasification reaction apparatus 201 according to a second embodiment of the present invention provided with a biomass supply hopper 208 and a coarse powder parallel gas supply line 206 .

[0101] In this embodiment, the N 2 , CO 2 , air, or a mixture thereof is sent from the coarse powder parallel gas supply line 206 into the interior of the biomass supply hopper 208 for temporarily storing the coarsely pulverized biomass pieces 205 as the coarse powder parallel gas 206a. Most of the coarse powder parallel gas is dropped and supplied into the primary gasification reaction chamber 202 through the biomass supply line 204 together with the biomass sheet 205 .

[0102] When the coarse powder parallel gas 206 a is not supplied, a large amount of water vapor introduced into the primary gasification reaction chamber 202 through the biomass supply line 204 flows into the biomass supply hopper 208 . Therefore, it is known from experime...

no. 3 Embodiment approach

[0109] Figure 6 It is a schematic diagram of a gasification reactor according to a third embodiment of the present invention further provided with a heat-resistant partition inside.

[0110] In this embodiment, the primary gasification reaction chamber 202 and the secondary gasification reaction tube 203 are separated by a heat-resistant partition wall 212 for the purpose of blocking radiant heat, and the primary gasification reaction chamber 202 forms a The reaction tube 203 is independent of the high temperature chamber 209 of the reaction furnace. The combustion gas generated in the high-temperature combustion gas generating device 101 is sent to the gasification reaction device 201 , and firstly heats the gasification reaction chamber 202 once, and then heats the gasification reaction tube 203 twice. The primary gasification reaction chamber 202 forms a reaction furnace high temperature chamber 209 independent of the secondary gasification reaction tube 203, so the prima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com